Novel intelligent one-piece flow hot-press gluing machine

A single-piece flow, gluing machine technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of repetitive labor, affect production efficiency, increase production cost, etc., to simplify the process and improve production efficiency. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

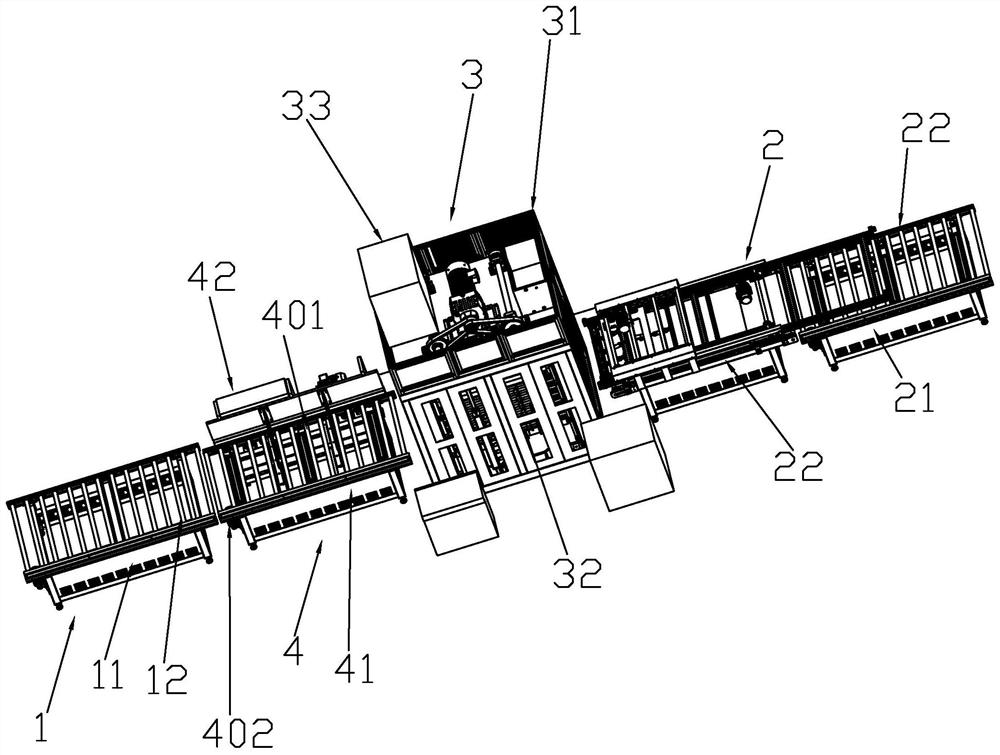

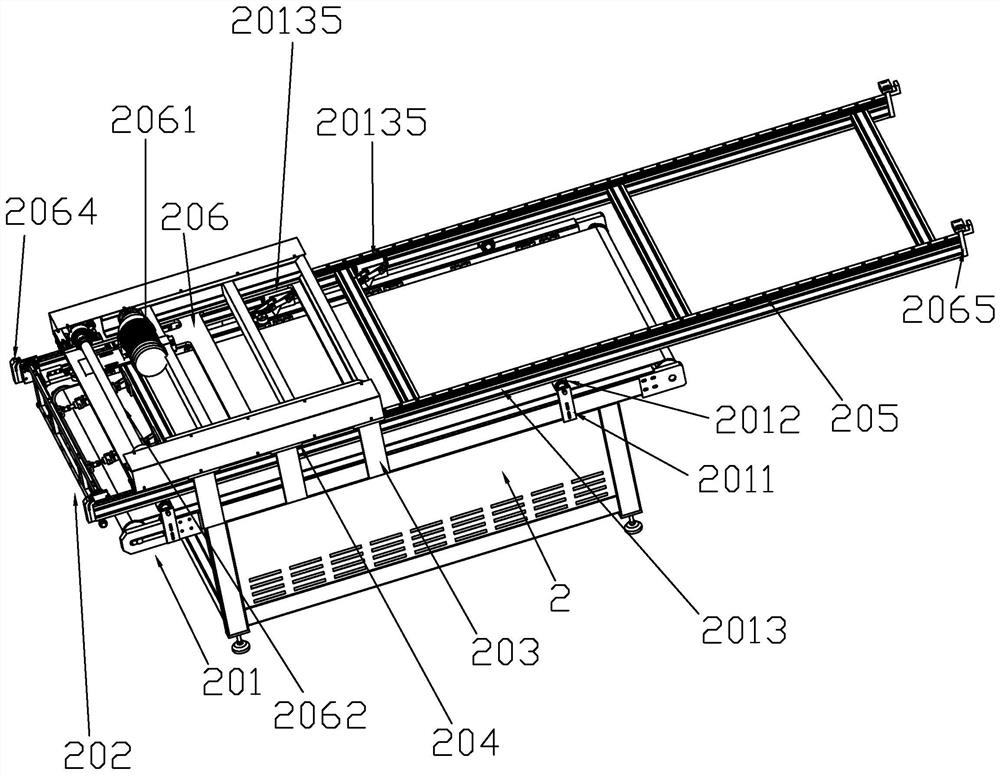

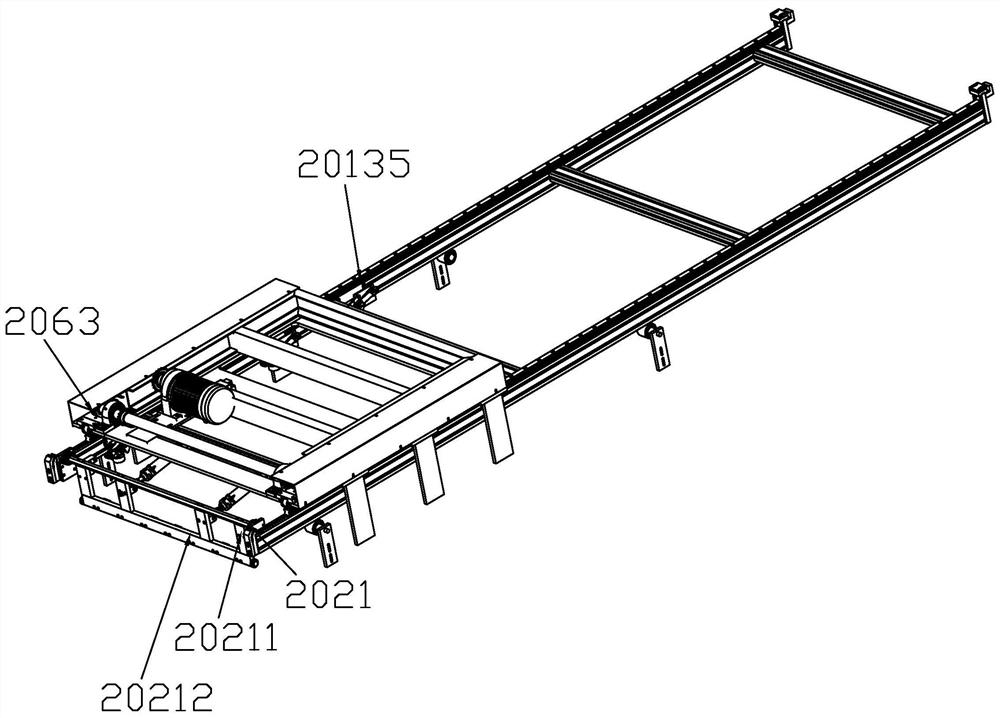

[0036] see Figure 1-Figure 18 Shown: a new type of intelligent single-piece flow hot-press gluing machine, including a gluing device 3, the gluing device 3 includes an organic body 31, a plurality of pressing plates 32 erected on the body 31 and arranged in stacks, and driving the pressing plates 32 to press or Separate driving mechanism, there is a pressing space between each pressing plate 32, and the body 31 is provided with a thermal energy generator 33 that can add heat energy to the inside of the pressing plate 32; In the body 31, the glued base 312 that is positioned at the lower part of the lowermost press plate 32 and can be vertically lifted along the body 31 and is arranged between the driving motor 311 and the glued base 312 can promote the transmission structure that the glued base 312 can be vertically lifted along the body. The glued base 312 and A first guide assembly is provided between the machine body 31, and a second guide assembly is provided between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com