Low-temperature-resistant medium-static-stiffness polyurethane microporous elastic base plate

A technology of microcellular elasticity and static stiffness, which is applied in the field of medium and static stiffness polyurethane microcellular elastic backing plates, can solve the problems of affecting the vibration reduction effect, decrease in elasticity, and high volume shrinkage rate of materials, so as to ensure the vibration reduction effect and increase the pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

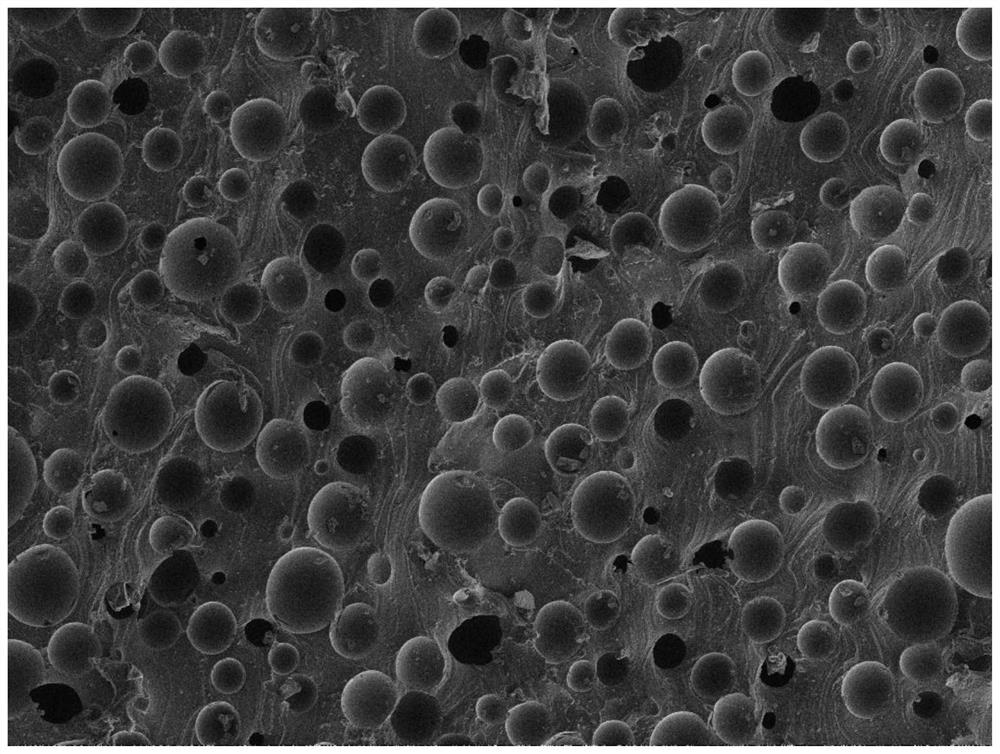

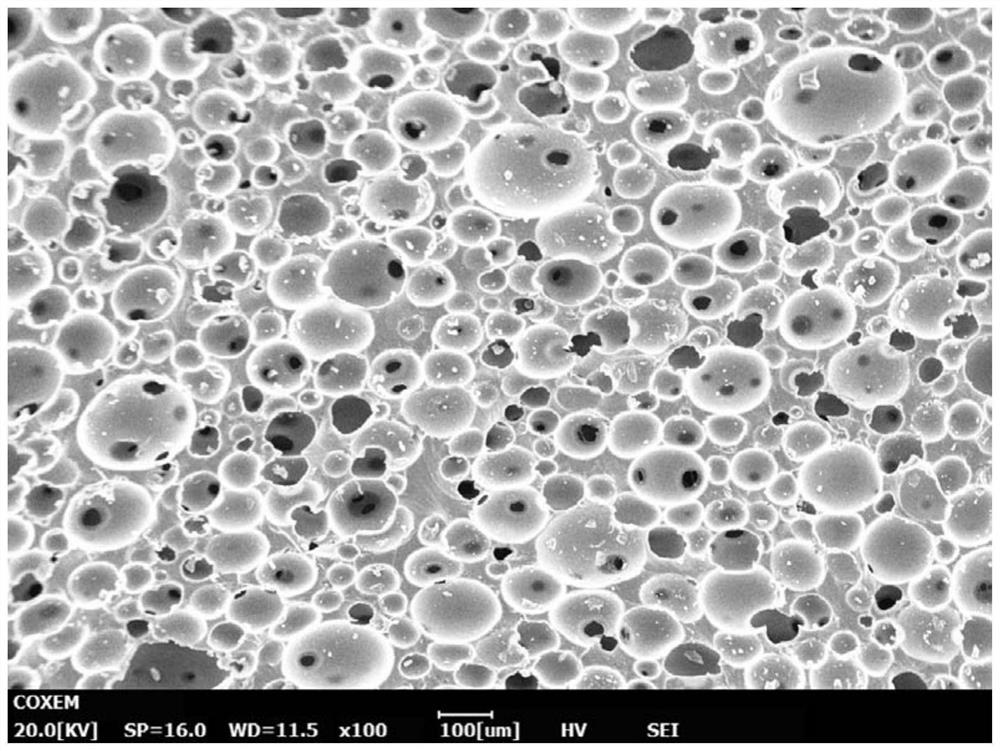

Image

Examples

Embodiment 1

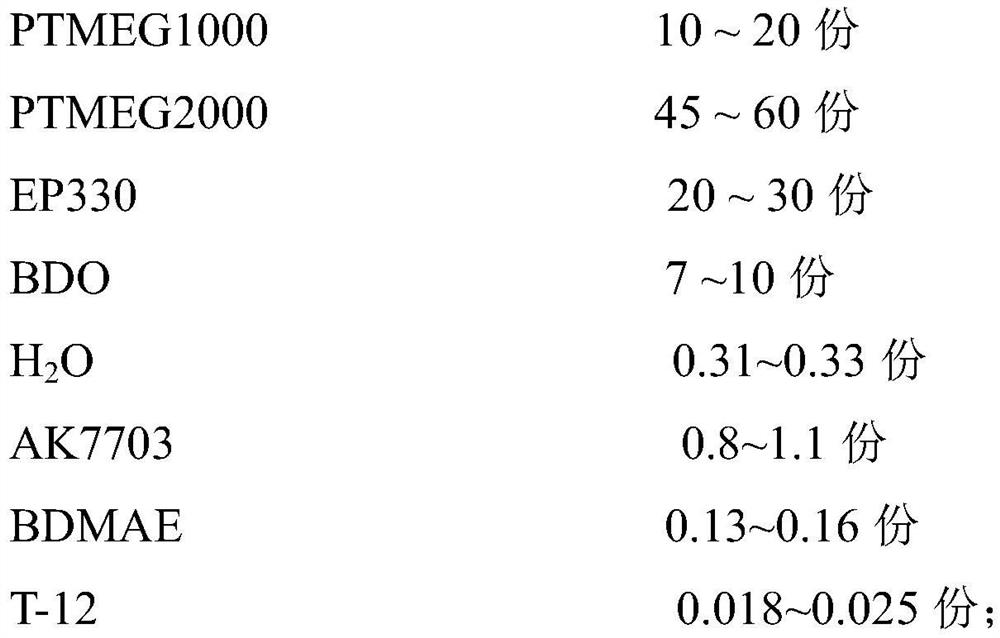

[0029] (1) 15 parts of PTMEG1000 (polytetrahydrofuran ether glycol with a functionality of 2 and a molecular weight of 1000), 51 parts of PTMEG2000 (polytetrahydrofuran ether glycol with a functionality of 2 and a molecular weight of 2000), 24.2 parts of EP330 (polytetrahydrofuran ether glycol with a functionality of 2, 3, polyoxypropylene triol with a molecular weight of 5000), 8.3 parts of BDO (1,4-butanediol), 0.31 parts of H 2 O, 1.03 parts of AK7703, 0.14 parts of BDMAE (bis(dimethylaminoethyl) ether) and 0.02 parts of T-12 (dibutyltin dilaurate) were mixed uniformly to obtain component A;

[0030]After mixing 50 parts of MDI (diphenylmethane diisocyanate), 30 parts of PTMEG1000 and 20 parts of PTMEG2000, under nitrogen protection atmosphere, stirred and reacted at 85°C for 4 hours to obtain component B with -NCO value of 13.39;

[0031] (2) According to the molar ratio of active -H in component A and -NCO group in component B: 1:1, component A preheated to 35°C and compo...

Embodiment 2

[0034] (1) 15 parts of PTMEG1000, 51 parts of PTMEG2000, 24.2 parts of EP330, 8.3 parts of BDO, 0.33 parts of H 2 O, 0.988 parts of AK7703, 0.16 parts of BDMAE and 0.022 parts of T-12 were mixed uniformly to obtain component A;

[0035] After mixing 50 parts of MDI, 30 parts of PTMEG1000 and 20 parts of PTMEG2000, under nitrogen protection atmosphere, stirred and reacted at 85°C for 4 hours to obtain component B with -NCO value of 13.39;

[0036] (2) According to the molar ratio of 1:1 molar ratio of active H in component A and -NCO group in component B, component A preheated to 35°C and component B preheated to 45°C were passed through two-component After the polyurethane pouring machine is mixed evenly, it is poured into a lockable mold preheated to 65°C, and the inner cavity volume is 868cm 3 Inject a mixture with a total mass of 434g into the mold, and then place the mold injected with the mixture at 65°C to cure for 10 minutes. After the mixture is expanded and molded, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com