Bacteriostatic dishwashing liquid capable of strongly emulsifying edible oil and preparation method of bacteriostatic dishwashing liquid

A technology of edible oil and dishwashing liquid, applied in the directions of biochemical equipment and methods, chemical instruments and methods, botany equipment and methods, etc., can solve the problem of poor practicability, poor antibacterial effect of dishwashing liquid, and inability to remove tableware Food oil and other problems, to achieve high-strength cleaning performance, enhance the effect of strong emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

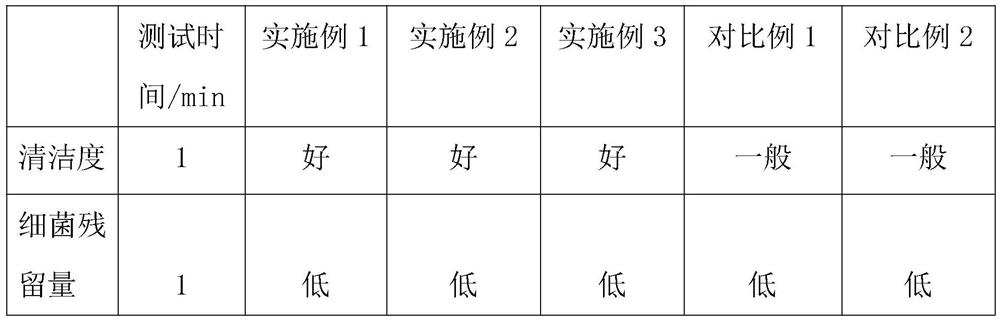

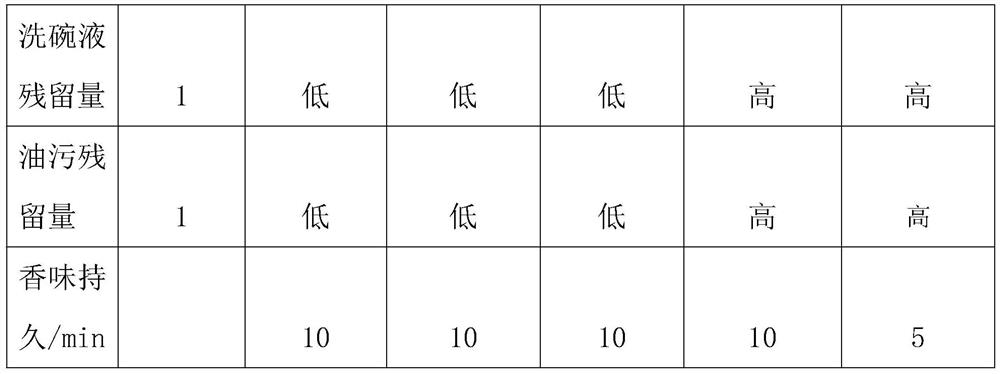

Examples

Embodiment 1

[0046] An antibacterial dishwashing liquid capable of strongly emulsifying edible oil and a preparation method thereof, wherein the antibacterial dishwashing liquid capable of strongly emulsifying edible oil comprises components A, B, C, D, E components and F components;

[0047] Described A component comprises the raw material of following mass percentage: Superemulsifier 5%, fatty alcohol polyoxyethylene ether ammonium sulfate 6% and lauryl dimethyl amine oxide 1%;

[0048] Described B component comprises the raw material of following mass percentage: coconut oil fatty acid diethanol amide 1% and cocamidopropyl amine oxide 20%;

[0049] The C component includes the following raw materials in mass percentage: 5% of alkyl glycoside and 1% of propylene glycol;

[0050] The D component includes the following raw materials in mass percentage: 0.1% triclosan and 0.2% alcohol;

[0051] The E component includes the following raw materials in mass percentage: 0.1% of fruity essence...

Embodiment 2

[0082] An antibacterial dishwashing liquid capable of strongly emulsifying edible oil and a preparation method thereof, wherein the antibacterial dishwashing liquid capable of strongly emulsifying edible oil comprises components A, B, C, D, E components and F components;

[0083] Described A component comprises the raw material of following mass percent: Superemulsifier 10%, fatty alcohol polyoxyethylene ether ammonium sulfate 12% and lauryl dimethyl amine oxide 5%;

[0084] Described B component comprises the raw material of following mass percentage: coconut oil fatty acid diethanol amide 4% and cocamidopropyl amine oxide 30%;

[0085] The C component includes the following raw materials in mass percentage: 10% of alkyl glucoside and 2% of propylene glycol;

[0086] The D component includes the following raw materials in mass percentage: 0.3% triclosan and 0.5% alcohol;

[0087] The E component includes the following raw materials in mass percentages: 0.5% fruity essence, ...

Embodiment 3

[0118] An antibacterial dishwashing liquid capable of strongly emulsifying edible oil and a preparation method thereof, wherein the antibacterial dishwashing liquid capable of strongly emulsifying edible oil comprises components A, B, C, D, E components and F components;

[0119] Described A component comprises the raw material of following mass percent: superemulsifier 8%, fatty alcohol polyoxyethylene ether ammonium sulfate 9% and lauryl dimethyl amine oxide 3%;

[0120] Described B component comprises the raw material of following mass percentage: coconut oil fatty acid diethanol amide 2% and cocamidopropyl amine oxide 25%;

[0121] The C component includes the following raw materials in mass percentage: 8% of alkyl glucoside and 1.5% of propylene glycol;

[0122] The D component includes the following raw materials in mass percentage: 0.2% triclosan and 0.35% alcohol;

[0123] The E component includes the following raw materials in mass percentage: 0.3% of fruity essence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com