Needle-beam rotary formwork full-circle lining trolley and its rotary formwork method for small-radius shield tunnels

A lining trolley and small-radius technology, which is applied in tunnel lining, shaft lining, tunnel, etc., can solve the problems of large construction interference, affecting construction progress, and many construction joints, so as to reduce construction interference, increase construction progress, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

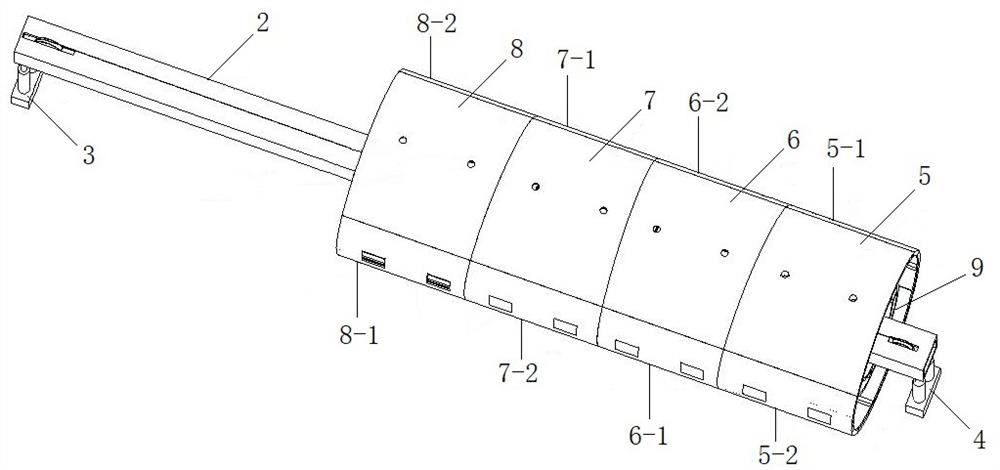

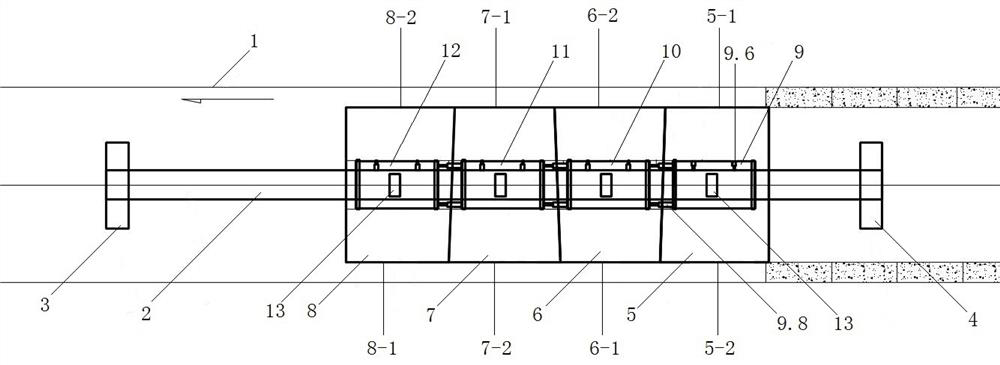

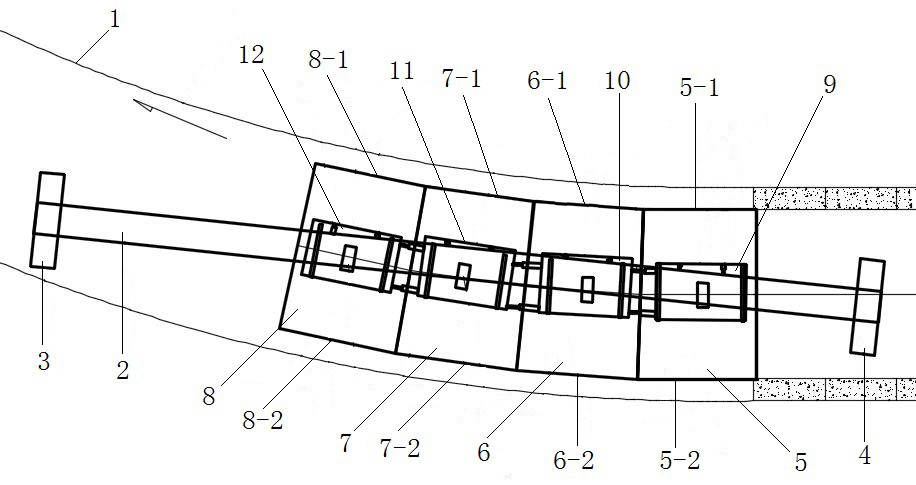

[0074] This embodiment provides a needle-beam rotary mold full-circle lining trolley for a small-radius shield tunnel, including a needle beam and a needle beam longitudinal movement system 2, a needle beam front support 3, a needle beam rear support 4, a rotation offset frame and template system;

[0075] Needle beam and needle beam longitudinal movement system 2 includes needle beam 2.1 and needle beam longitudinal movement device; needle beam 2.1 is a box-shaped hollow structure made of steel, and two pulley holes 2.4 are arranged longitudinally on the top plate; needle beam longitudinal movement The device includes wire rope 2.2.2, wire rope retractable mechanism, pulley 2.2.6, self-aligning bearing 2.2.7 and needle beam hinge ear 2.2.8; the needle beam hinge ear 2.2.8 is set on both sides of the pulley hole 2.4, and is located Inside the beam 2.1; the wheel shaft of the pulley 2.2.6 is rotationally connected with the needle beam hinge ear 2.2.8 through the self-aligning b...

Embodiment 2

[0101] This embodiment provides a method for rotating the formwork of the needle-beam type rotating formwork full-circle lining trolley for the small-radius shield tunnel described in Embodiment 1, which is divided into straight line section construction and curved section construction.

[0102] When constructing a straight line section, the following steps are included:

[0103] S1, elongate the needle beam front support 3 and the needle beam rear support 4, so that the needle beam 2.1 supports the rotation offset frame and formwork system;

[0104] S2, separation of formwork system: through the frame clutch mechanism, each formwork is separated longitudinally along the needle beam 2.1, specifically, all the frame clutch cylinders 9.8 are extended, so that each rotation offset frame and the formwork connected to it are separated longitudinally;

[0105] S3, lifting the counterweight system 13: operate all counterweight cylinders 13.2, lift all counterweight blocks 13.1 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com