Spray water valve group

A water valve and main control valve technology, applied in servo motor components, struts/brackets, dustproof, etc., can solve the problems of electromagnetic pilot valve damage, stuck, blocked, etc., to achieve the effect of normal temperature and ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

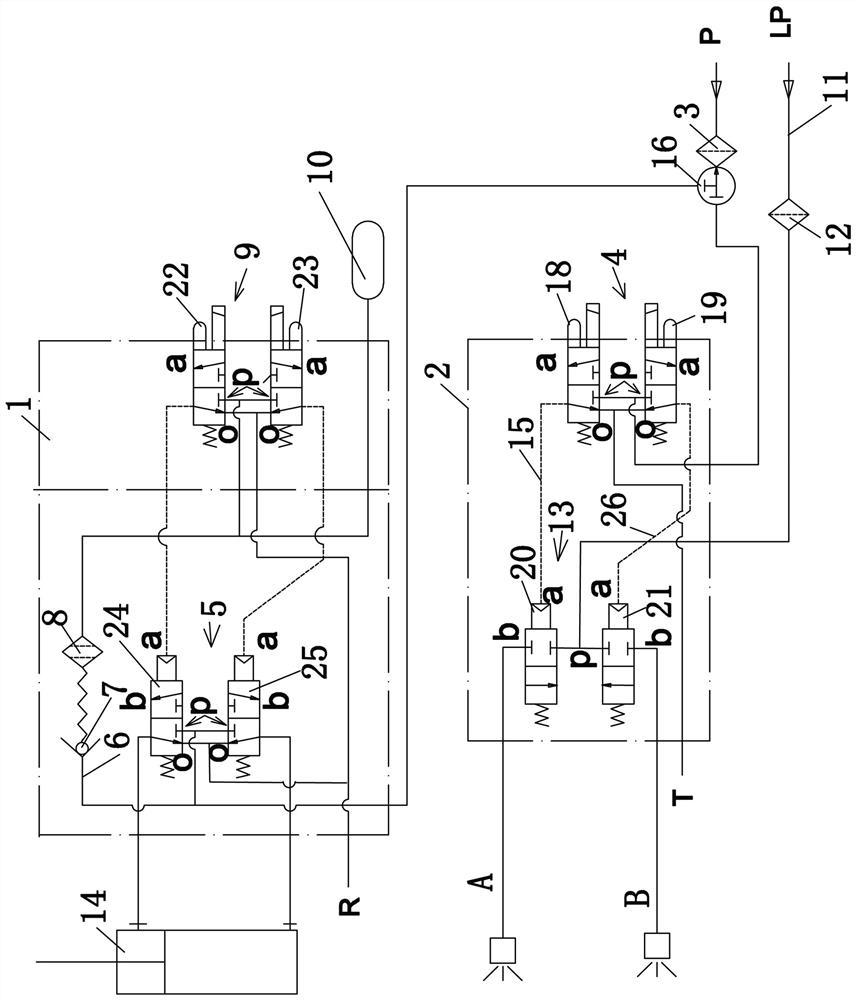

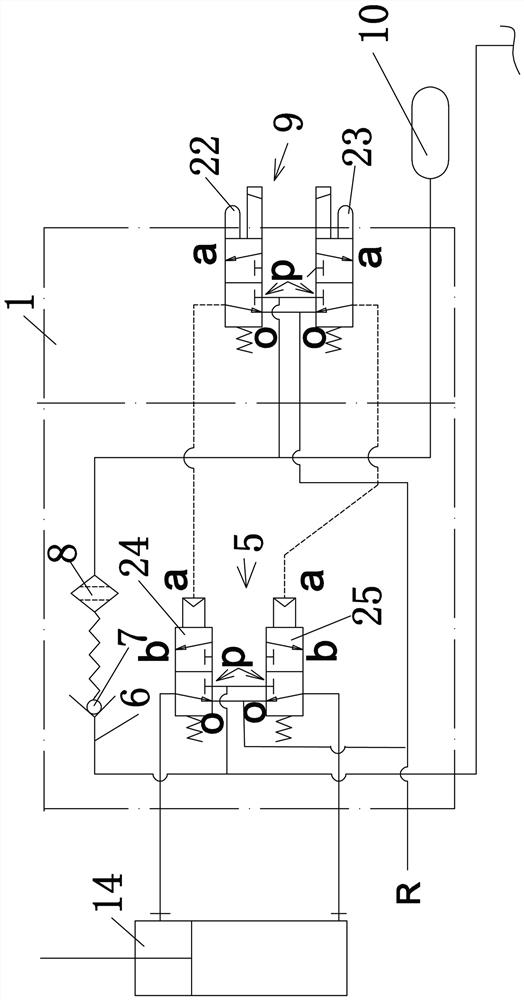

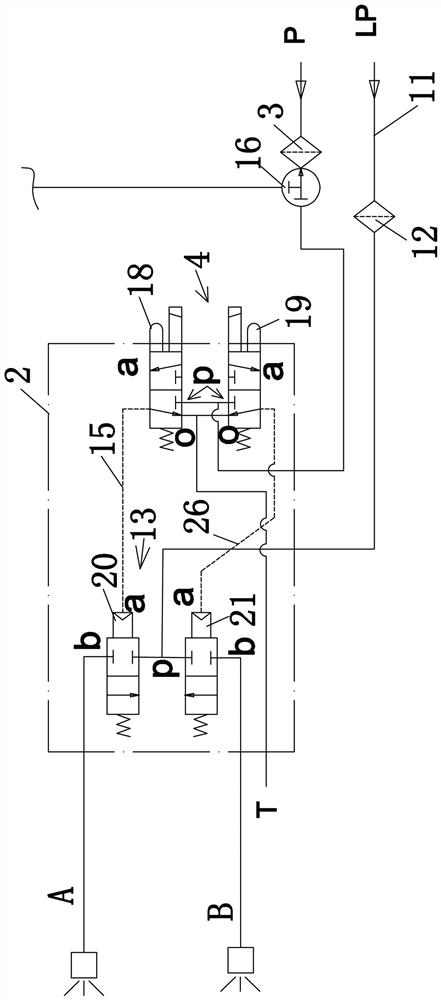

[0046] take a look first figure 1 The difference between the liquid supply line:

[0047] The electro-hydraulic reversing valve group 1 and the spray water valve group 2 are respectively the parts in the corresponding dot-dash line frame, which is a known technology.

[0048] The high-pressure emulsion P is divided into two liquid paths through the main filter 3 (filter precision 40 μm) and the original three-way joint 16: one joint supplies liquid to the electromagnetic pilot valve 4 of the spray water valve through the high-pressure rubber hose. One way enters the electro-hydraulic reversing valve group 1 through the high-pressure rubber hose, and is divided into two hydraulic circuits in the valve group. One liquid circuit supplies liquid to the main valve 5 of the large-flow electro-hydraulic reversing valve, and the other passes through the damping hole 6 and the damping check valve. 7. After the pilot valve filter 8, it is divided into two liquid circuits, one supplying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com