Curtain grouting method for large-space large-dip-angle goaf

A technology of curtain grouting and goaf, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems that large-space curtain grouting cannot be realized, so as to improve construction efficiency, reduce project cost, and ensure The effect of barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

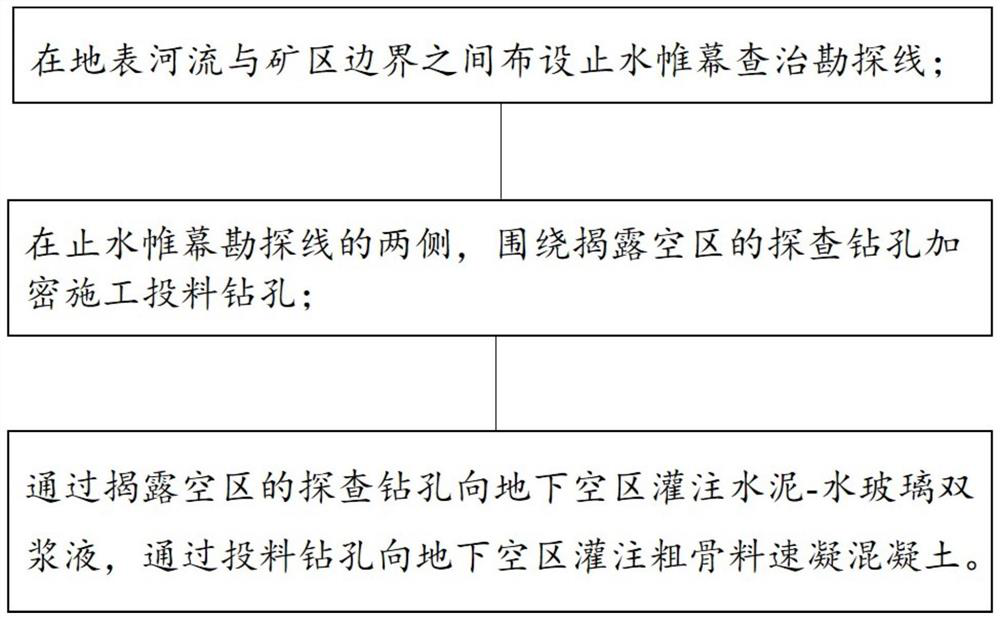

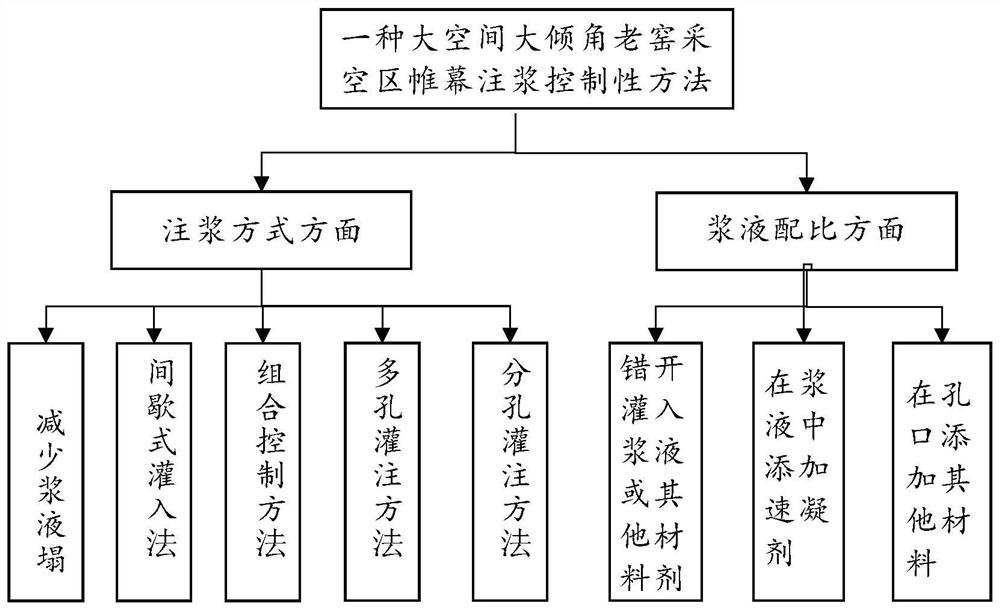

[0038] A specific embodiment of the present invention discloses a curtain grouting method for gobs with large space and large inclination angle, the operation flow is as follows figure 1 As shown, the grouting control principle is as follows figure 2 As shown, the method includes the following steps:

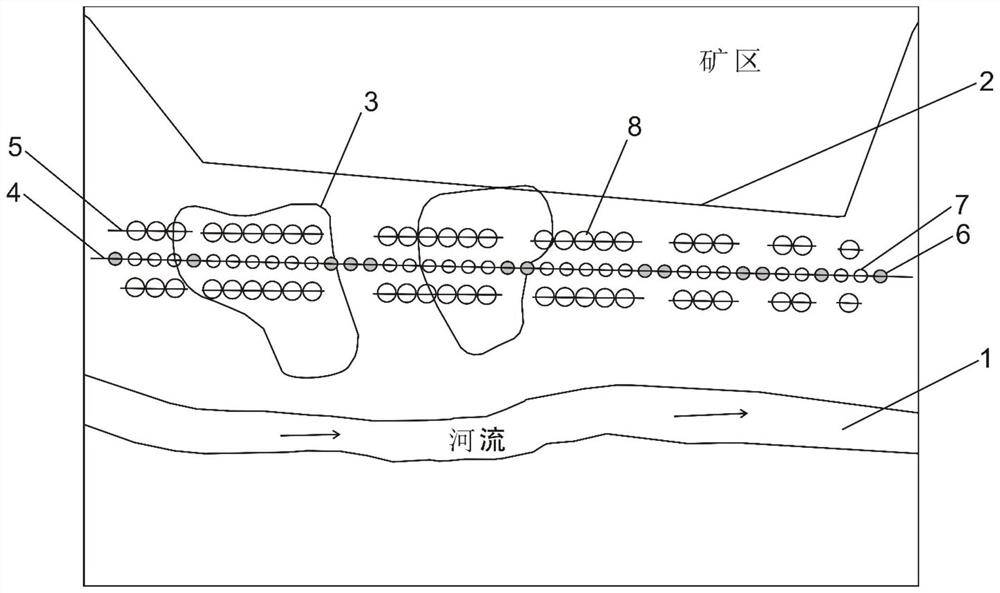

[0039] Set up a water-stop curtain inspection and exploration line between the surface river and the boundary of the mining area, and the water-stop curtain inspection and inspection line passes through the underground space in the mining area to be treated;

[0040] On both sides of the water-stop curtain exploration line, around the exploratory boreholes that expose the void area, the construction feeding boreholes are intensified. The empty area is poured with coarse aggregate quick-setting concrete.

[0041] In this embodiment, the goaf with large space and large inclination angle means that the height of the goaf is greater than or equal to 4m, and the inclination angle ...

Embodiment 2

[0097] Yet another specific embodiment of the present invention discloses a method for curtain grouting in goafs with large space and large inclination, which is improved on the basis of Embodiment 1. Before grouting in the interior, carry out hydrological tracer test, based on the hydrological tracer test, accurately determine the key blocked water passages and estimate the required amount of mud.

[0098] Before grouting in the exploration borehole 7 of the exposed void area, when the proposed grouting water plugging curtain exploration borehole detects an old void or old lane, select one or more in the dense feeding borehole 8 The feeding borehole 8 is used as a temporary hydrological observation hole 9. After the monitoring task is completed, the temporary hydrological observation hole 9 and other feeding boreholes 8 are plugged with feeding grouting, and a permanent hydrological observation hole 10 is constructed outside the encrypted feeding line 5. The depth of the hydrol...

Embodiment 3

[0107] Since the suitable construction time in high-altitude areas is only from April to May each year, the suitable construction time is very short. Traditionally, the existing method of first detection and then treatment is adopted. It is necessary to find all the water passages first, and then build the underground waterproof curtain. It is impossible to complete the exploration and construction of the underground waterproof curtain wall in just two months, and it is difficult to complete the construction of the curtain wall within a suitable construction period.

[0108] Based on the above problems, another specific embodiment of the present invention, on the basis of Embodiment 1 and Embodiment 2, discloses a curtain grouting method for large-space and large-inclination goafs. During the construction of the exploratory drilling on the water-stop curtain inspection and exploration line 4, grouting is carried out in the exploratory drilling 7 of the exposed empty area to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com