Zero-cold-water functional waterway capable of realizing telescopic vertical water replenishing

A scalable, zero-cold water technology, applied in the direction of functional valve type, valve operation/release device, valve housing structure, etc., can solve the problems of impurities entering, reducing the service life of the pump, and being unable to adapt, so as to prevent condensed water Access, improved sealing performance, reliable and reasonable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

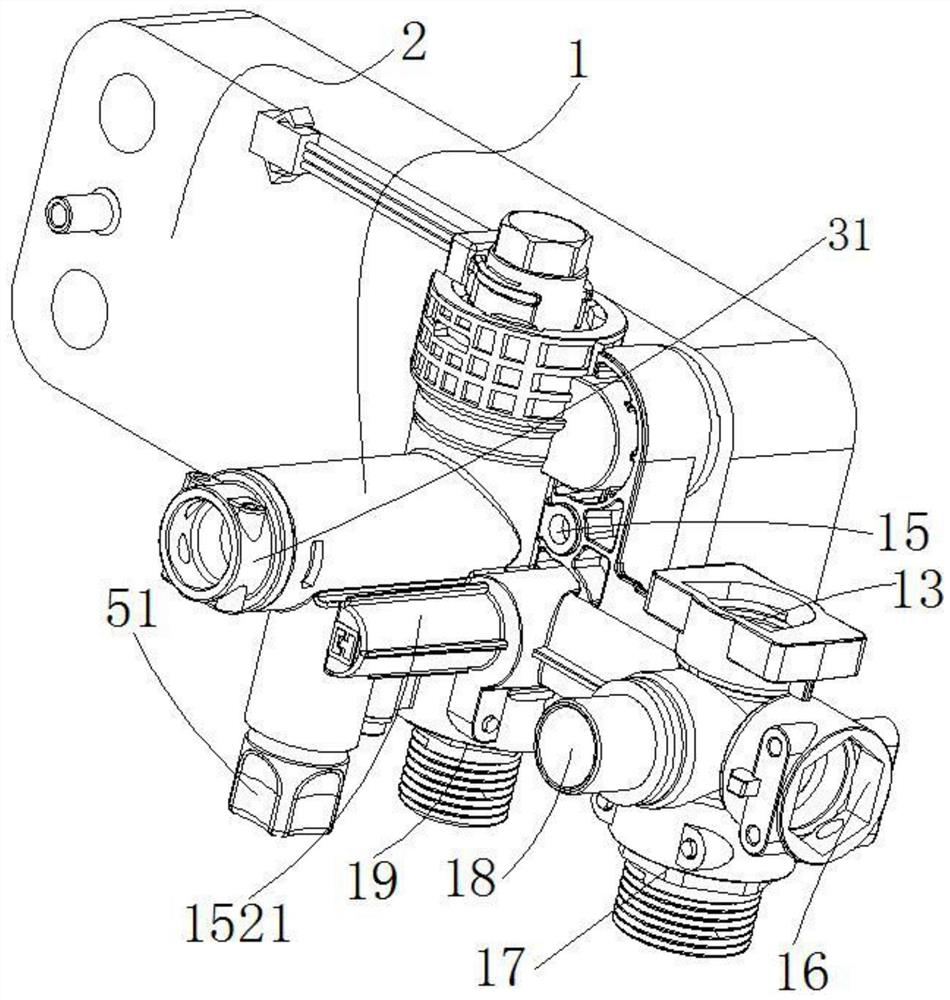

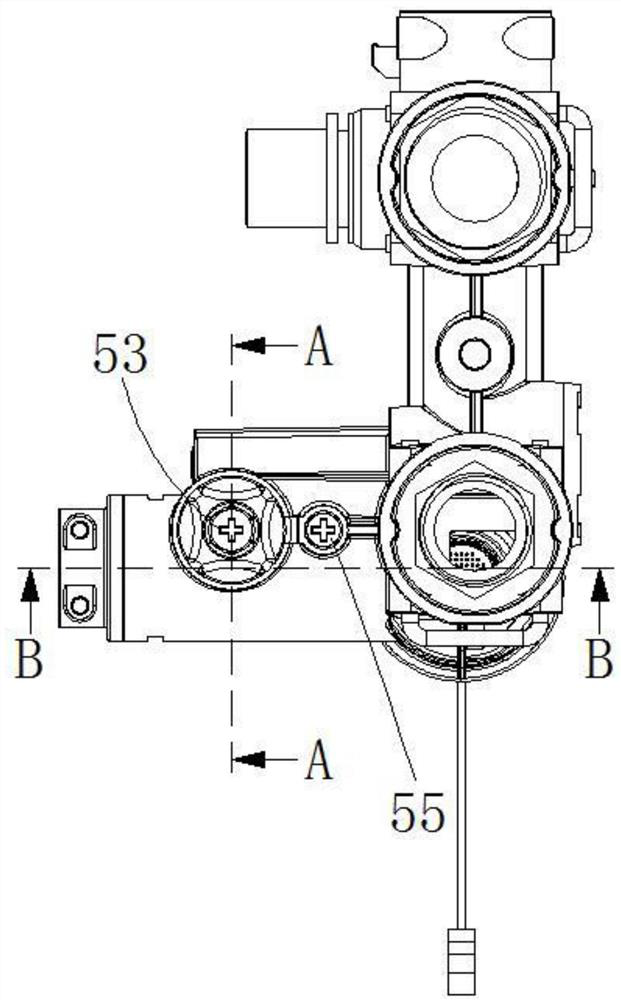

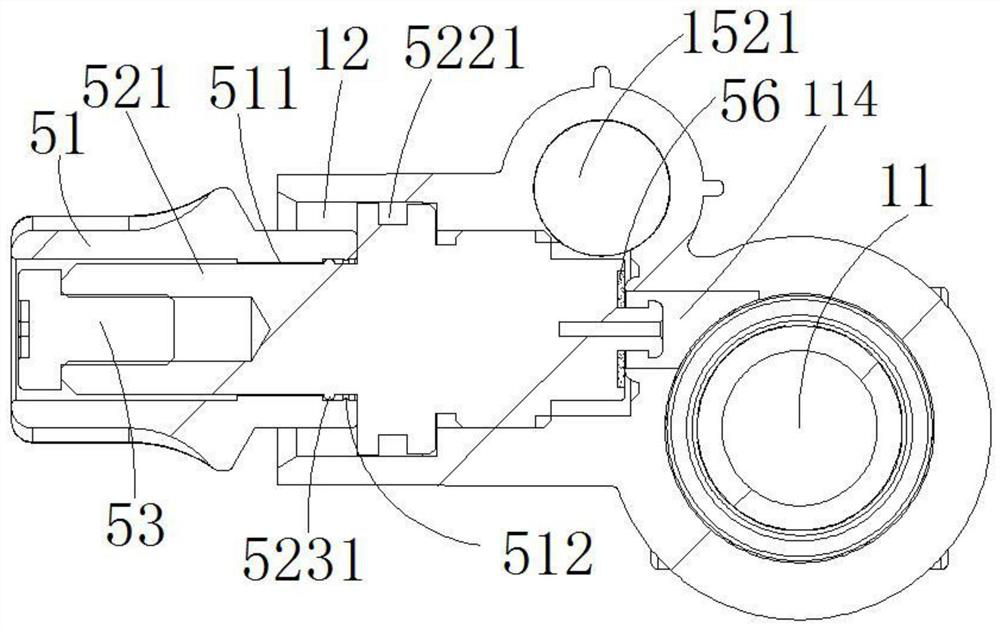

[0045] like Figure 1 to Figure 14 As shown, a zero-cold water functional waterway with scalable vertical replenishment includes a casing 1 made of plastic material.

[0046] The housing 1 includes a water supply channel 11, a water supply control channel 12, a water inlet channel 19, a water outlet channel 151, a hot water channel 152 and a water pump interface 18, the hot water channel 152 communicates with the water pump interface 18, and the water inlet channel 19 and the water outlet channel 151 are communicated by the water channel 14, what circulate in the water inlet channel 19, the water outlet channel 151, the water channel 14 is normal temperature water, and a flow sensor is installed in the water channel 14.

[0047] The housing 1 includes a safety valve seat 13 communicating with a hot water channel 152 , an expansion tank seat 16 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com