Air supply pipe joint leakage detection alarm device

A leakage detection and alarm device technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of untimely alarm, high labor intensity, and many pipe joints under the vehicle, so as to improve work efficiency, The effect of reducing labor intensity and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

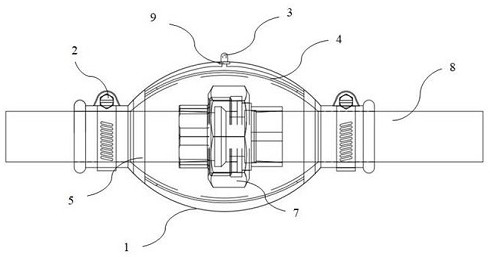

[0039] Such as figure 1 As shown, the leakage detection and alarm device for air supply pipe joints in this embodiment includes: a sealing capsule 1; a sealing and fastening device 2; an alarm 3; a piezoelectric sheet 4; a collector ring 5;

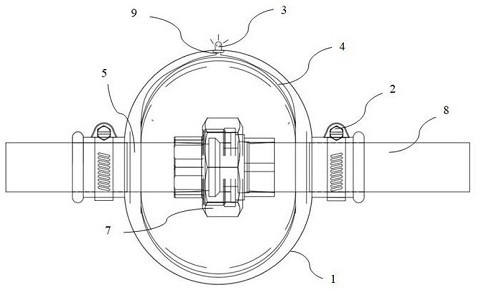

[0040] Wherein, the sealing capsule 1 is wrapped outside the air supply pipe joint 7; made of flexible rubber, the two ends of the sealing capsule 1 are sleeved on the air supply pipe 8, and the sealing device 2 is used to further fix the sealing capsule 1 on the air supply pipe 8, to avoid the relative displacement of the two ends of the sealed capsule 1 relative to the air supply pipe 8 due to the deformation of the middle position of the sealed capsule 1; to completely eliminate the leakage of the air supply pipe joint; when the sealed capsule 1 is in a non-alarm state oval in shape; figure 2 As shown, the sealed capsule 1 is circular when in the alarm state. The piezoelectric sheets 4 are arranged on the upper and lower sides of th...

Embodiment 2

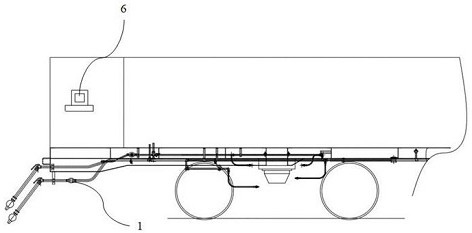

[0049] Compared with Embodiment 1, a photoelectric sensor is used to replace the position sensor 9 in this embodiment, and the photoelectric sensor is connected in parallel with the alarm 3, and the alarm 3 here also sends out an alarm signal by flashing the alarm light. After the photoelectric sensor detects the alarm signal, the alarm signal and the alarm position are also sent to the integrated alarm display 6 through wireless transmission.

[0050] From the description in Embodiment 1, it can be seen that because the deformation of the piezoelectric sheet 4 is not accomplished overnight, the generated voltage is also increased from small to large; as Figure 4 As shown, the alarm device 3 and the position sensor 9 in Embodiment 1 are connected in series. Since the rated voltages of the two are different, when the rated voltage of the alarm device 3 is lower than the position sensor 9, when the alarm device 3 sends an alarm signal, The position sensor 9 does not send the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com