Method and device for multi-objective optimization of moea/d extrusion process parameters

A multi-objective optimization and process parameter technology, applied in data processing applications, forecasting, instruments, etc., to achieve good population diversity and convergence, reduce mold wear, and improve yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

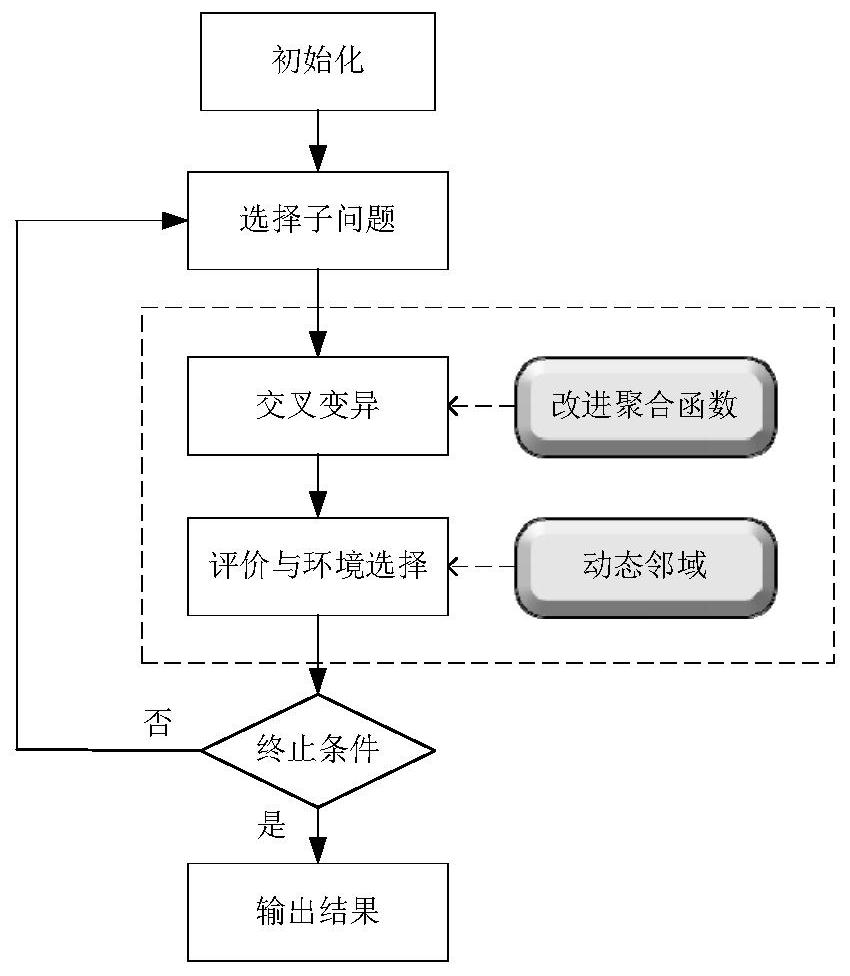

Method used

Image

Examples

Embodiment

[0119] 1. Evaluation indicators

[0120] The anti-generational distance evaluation index IGD is the average value of the minimum distance between the actual PF individual and the approximate solution set obtained by the algorithm. Therefore, the smaller the value of IGD, the better the convergence and distribution of the algorithm. IGD is calculated as follows:

[0121]

[0122] Hypervolume evaluation means that HV calculates a set of algorithm PF approximate solutions and distributes them at the reference point of the target space governs the volume of the target space, the formula is as follows:

[0123]

[0124] In the formula, VLO(·) represents the Lebesgue measure. The larger the HV value, the more S is similar to the entire PF, so the higher the HV value, the better the convergence and distribution of the algorithm.

[0125] 2. Algorithm comparison

[0126] 2.1. Parameter setting

[0127] In order to verify the performance of the improved MOEA / D algorithm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com