Solvent extraction method and solvent extraction equipment

An extraction equipment and solvent technology, applied in the field of mass transfer and separation, can solve the problems of lower mass transfer ratio, lower extraction efficiency, and poor absorption of solute by the extractant, so as to improve mass transfer ratio, reduce back-mixing, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

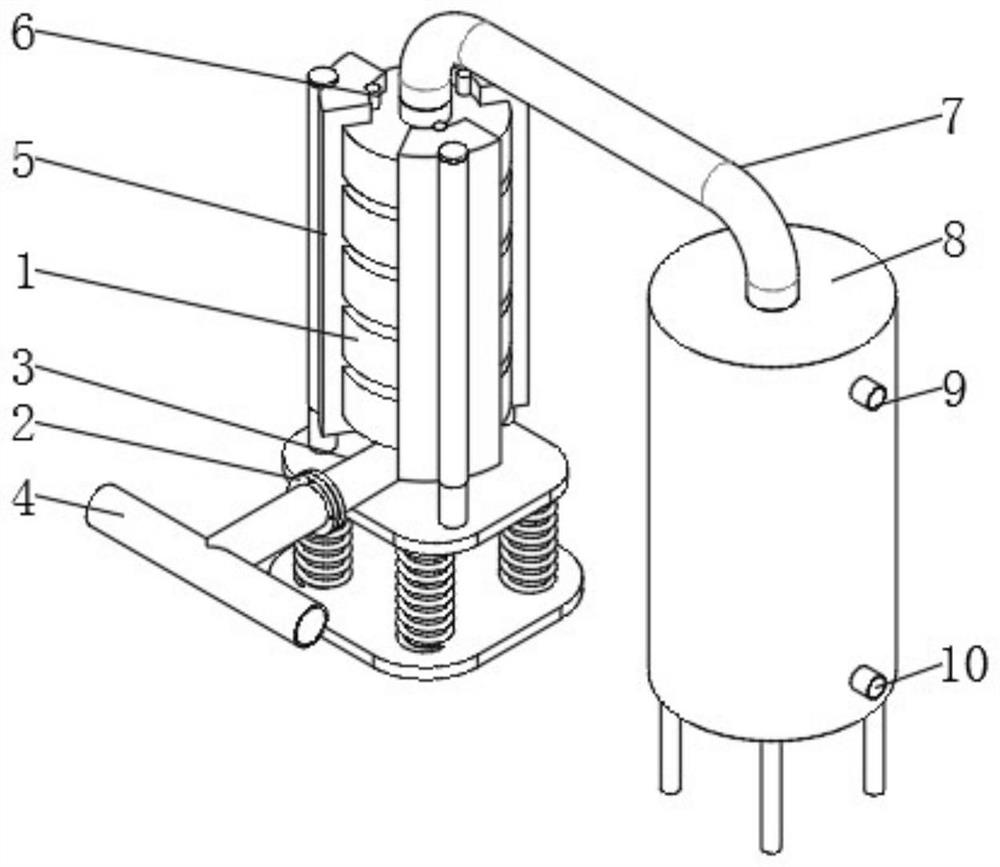

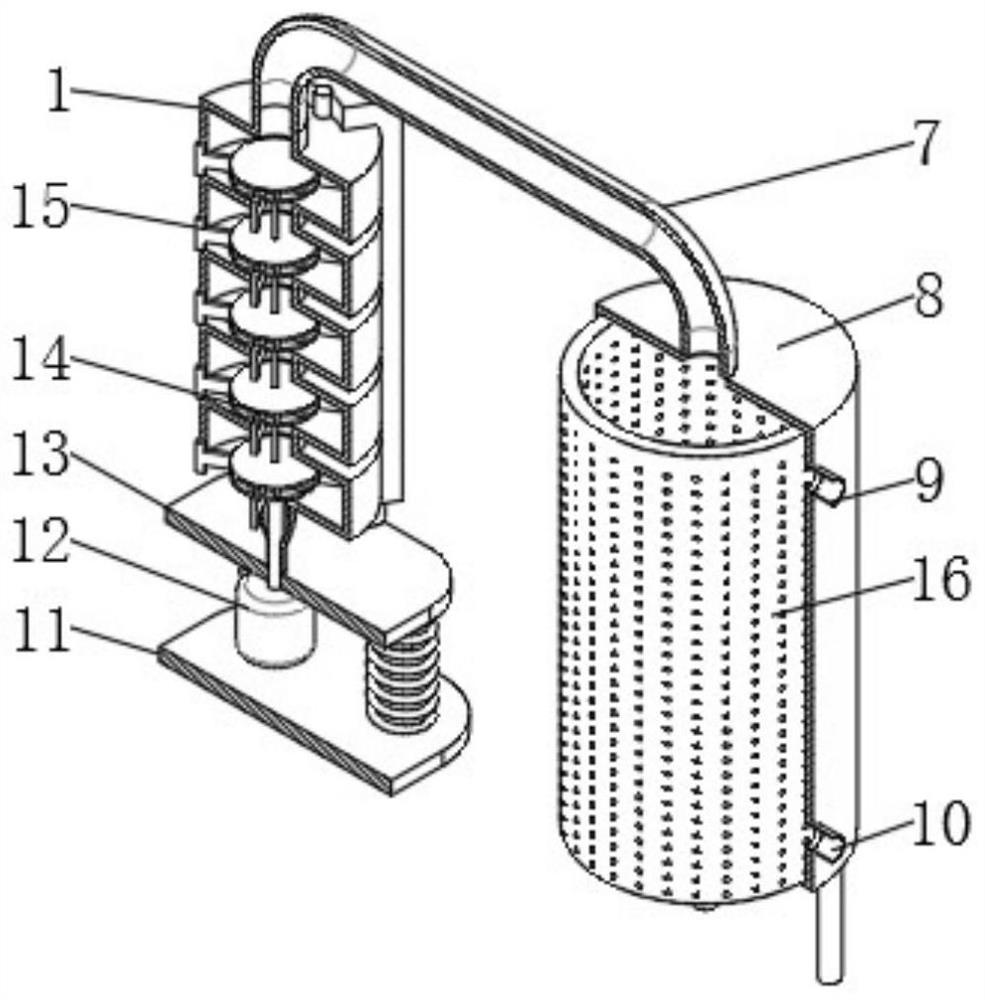

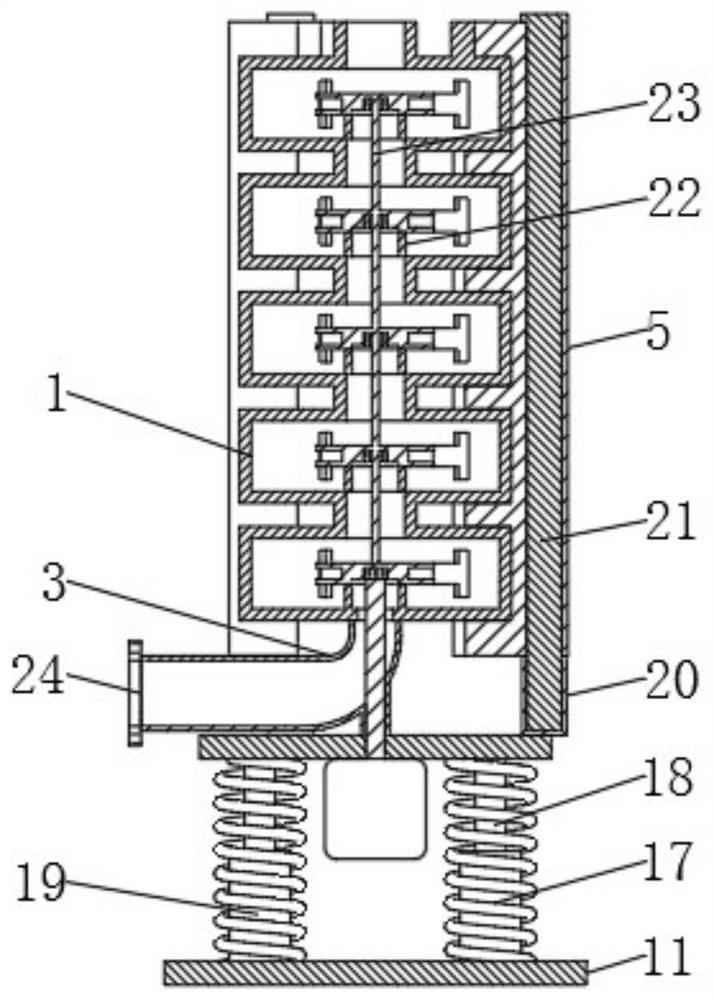

[0031] Example: Reference figure 1 , 2 A solvent extraction equipment shown in 3 and 4 includes an extraction tower 1 and a plurality of fixed components. The inner wall of the extraction tower 1 is provided with a plurality of stirring chambers distributed at equal distances, and a plurality of stirring chambers are connected in series to form a tower-shaped structure, The extraction tower 1 can be any base structure in the prior art, such as a metal box

[0032] Sealing cylinders 22 are fixedly installed in the middle parts of the inner walls of the bottoms of the plurality of stirring chambers, and centrifugal impellers 14 are installed on the tops of the plurality of sealing cylinders 22 rotatably. Inside 22, the sealing cylinder 22 ensures that the centrifugal impeller 14 axially enters the liquid smoothly.

[0033] The tops of the plurality of centrifugal impellers 14 are provided with fixing holes, the connecting rods 23 are fixedly installed in the plurality of fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com