Natural gas catalytic desulfurization purification device and process

A purification device and catalytic desulfurization technology, which is applied in the direction of combined devices, gas fuel, gas treatment, etc., and can solve problems such as removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

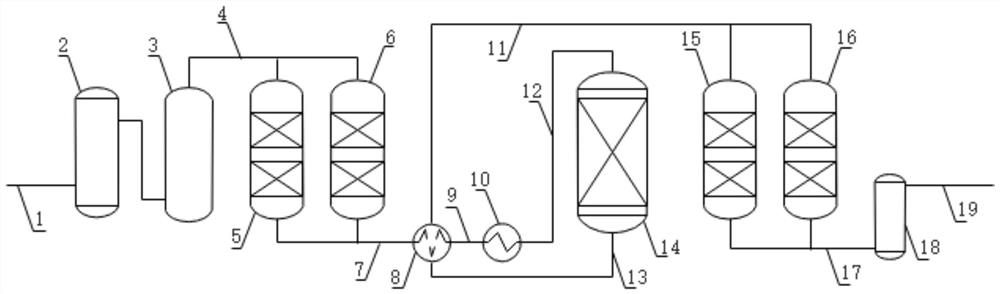

[0023] A catalytic desulfurization purification device for natural gas, comprising a gravity separator 2, a filter separator 3, a primary fine desulfurization device, a heat exchange device 8, a heating device 10, a catalytic conversion device 14, a secondary fine desulfurization device, and a dust filter 18, Valves, air source (connection) pipes.

[0024] The raw natural gas is transported by the pressurization station, and the gravity separator 2 removes impurities, and the filter separator 3 removes hydrocarbon liquid and moisture. 2 S, after being preheated by the heat exchange device 8, the heater (heating device 10) is heated to an appropriate reaction temperature, enters the catalytic conversion device 14, and organic sulfur, especially COS, CS 2 , mercaptan, thioether and other sulfides are converted into H 2 S form, after cooling through the heat exchange device 8 again, enter the secondary fine desulfurization device to remove the conversion product H 2 S, the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com