Bonding breakout logical judgment method based on space-time sequence characteristics

A technology of logical judgment and steel leakage, applied in the configuration of indicating equipment/measuring equipment, image enhancement, instruments, etc., can solve the problem of many false alarms and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

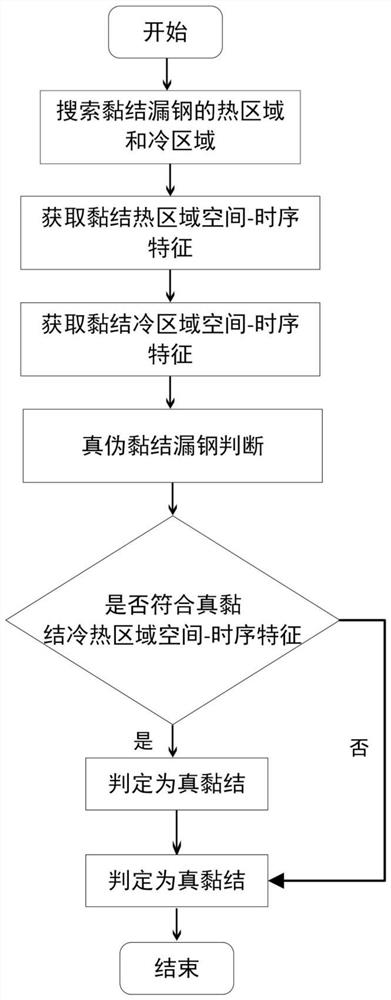

[0035] like figure 1 As shown, a method for logically judging bonded breakout based on space-sequential features of the present invention includes the following steps:

[0036] 1) Search for hot and cold areas of bonded breakout

[0037] (1) According to the abnormal bonding area and on-site inspection results, establish a sample database of casting billet bonding in the mold;

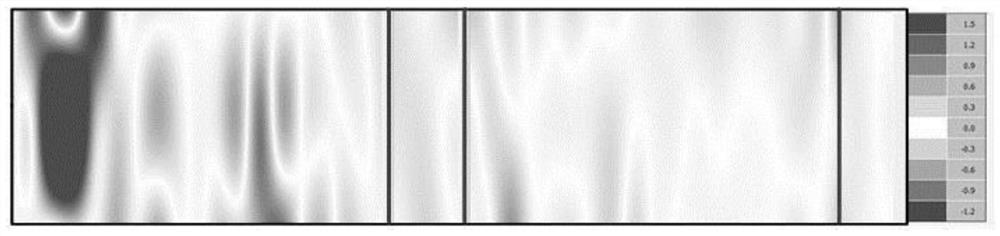

[0038](2) Based on the continuous casting mold breakout visualization monitoring system, the abnormal bonding area in the mold is visualized, and the thermal image is as follows figure 2 shown;

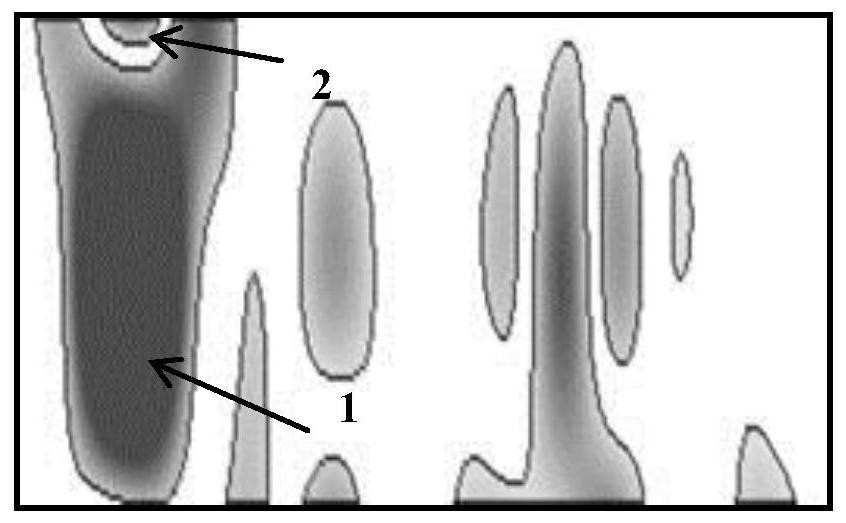

[0039] (3) Search for hot and cold areas of bonded breakout;

[0040] 2) Obtain the space-sequential features of the hot area of the bond breakout

[0041] (1) Obtain the characteristics of the hot zone area, and determine the maximum value S of the hot zone area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com