Ship noise reduction plate and preparation method thereof

A technology for noise reduction panels and ships, applied in the direction of hull paneling, chemical instruments and methods, hull, etc., can solve the problems of multi-directional noise that is difficult to deal with, cannot be cut off transmission, etc., achieve low density, reduce quality, and enhance compression resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

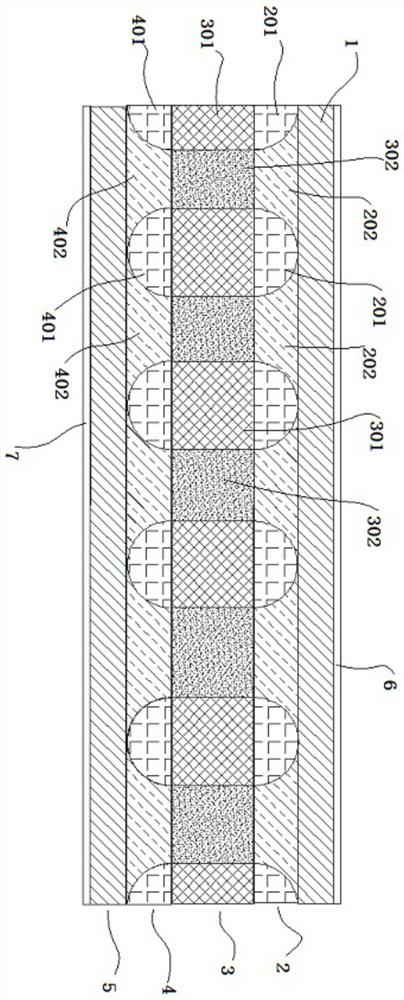

[0038] This embodiment provides a ship noise reduction board, the specific manufacturing method is as follows:

[0039] (1) Manufacture the first sound-absorbing and insulating composite panel and the third sound-absorbing and insulating composite panel formed in one piece:

[0040] The butyl rubber body is dug out to fill the expanded polytetrafluoroethylene cavity, and then the inner wall of the cavity is coated with epoxy resin adhesive, and then the expanded polytetrafluoroethylene treated with naphthalene sodium liquid is filled to the In the cavity, the first sound-absorbing and insulating composite board and the third sound-absorbing and insulating composite board integrally prepared are obtained.

[0041] (2) Manufacture the second sound-absorbing and insulating composite panel integrally formed: dig out a cavity for butyl rubber on the glass wool main body, then apply epoxy resin adhesive inside the cavity, and then fill the butyl rubber into the cavity to obtain the...

Embodiment 2

[0054] This embodiment provides a ship noise reduction board, the specific manufacturing method is as follows:

[0055] (1) Manufacture the first sound-absorbing and insulating composite panel and the third sound-absorbing and insulating composite panel formed in one piece:

[0056] The butyl rubber body is dug out to fill the expanded polytetrafluoroethylene cavity, and then the inner wall of the cavity is coated with epoxy resin adhesive, and then the expanded polytetrafluoroethylene treated with naphthalene sodium liquid is filled to the In the cavity, the first sound-absorbing and insulating composite board and the third sound-absorbing and insulating composite board integrally prepared are obtained.

[0057] (2) Manufacture the second sound-absorbing and insulating composite board according to the above method.

[0058](3) The first metal plate and a sound-absorbing composite board are bonded with an epoxy resin adhesive, the third sound-absorbing composite board and the...

Embodiment 3

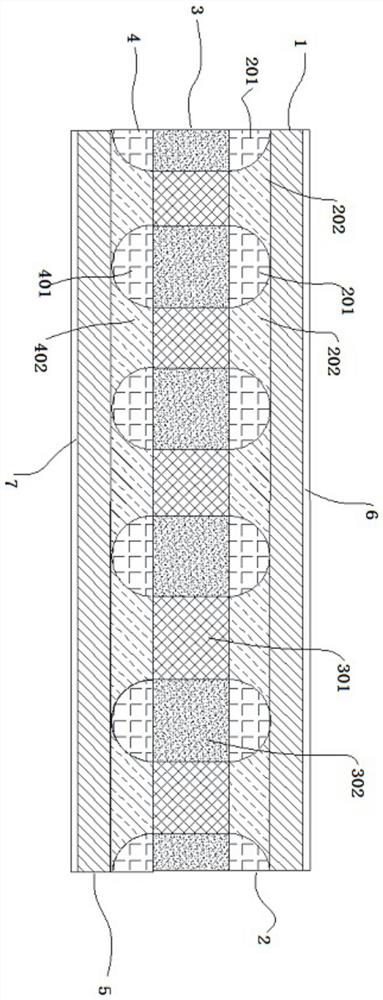

[0070] This embodiment provides a ship noise reduction board, the specific manufacturing method is as follows:

[0071] (1) Manufacture the first sound-absorbing and insulating composite panel and the third sound-absorbing and insulating composite panel formed in one piece:

[0072] A cavity for butyl rubber is dug out on the main body of glass wool, and then epoxy resin adhesive is coated inside the cavity, and then butyl rubber is filled into the cavity to obtain the first sound-absorbing and insulating compound prepared in one piece board and the third sound-absorbing and insulating composite board.

[0073] (2) Manufacture the integrally formed second sound-absorbing and insulating composite board according to the above method.

[0074] (3) The first metal plate and a sound-absorbing composite board are bonded with an epoxy resin adhesive, the third sound-absorbing composite board and the second metal plate are bonded with an epoxy resin adhesive, and the second metal pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com