Construction method of lock catch steel pipe pile cofferdam suitable for thin covering layer hard riverbed

A construction method and technology of steel pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficult construction and high cost, and achieve the effect of fast construction progress, high bending rigidity and good waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

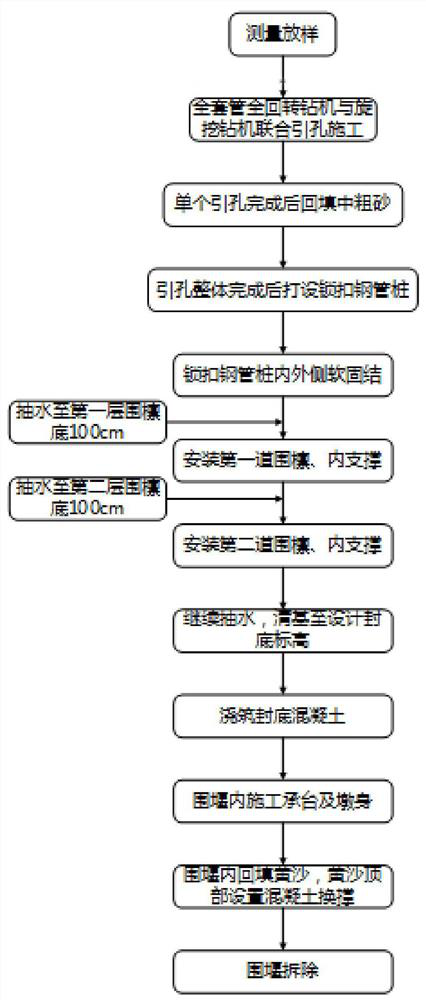

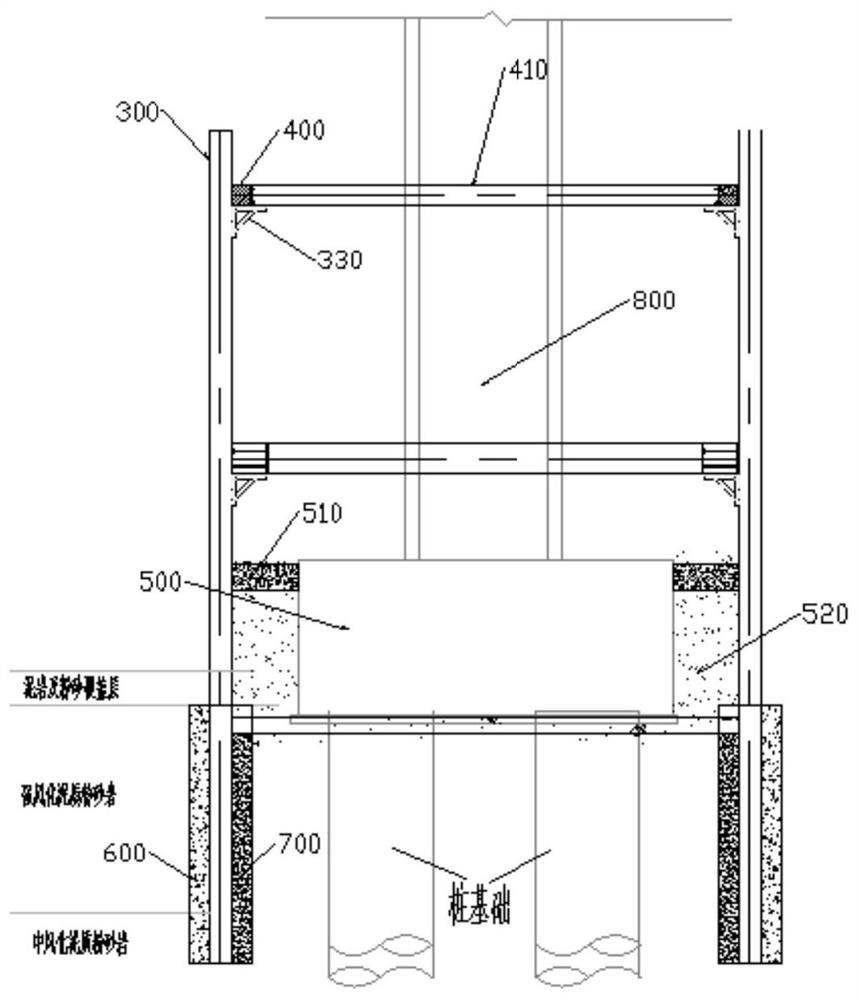

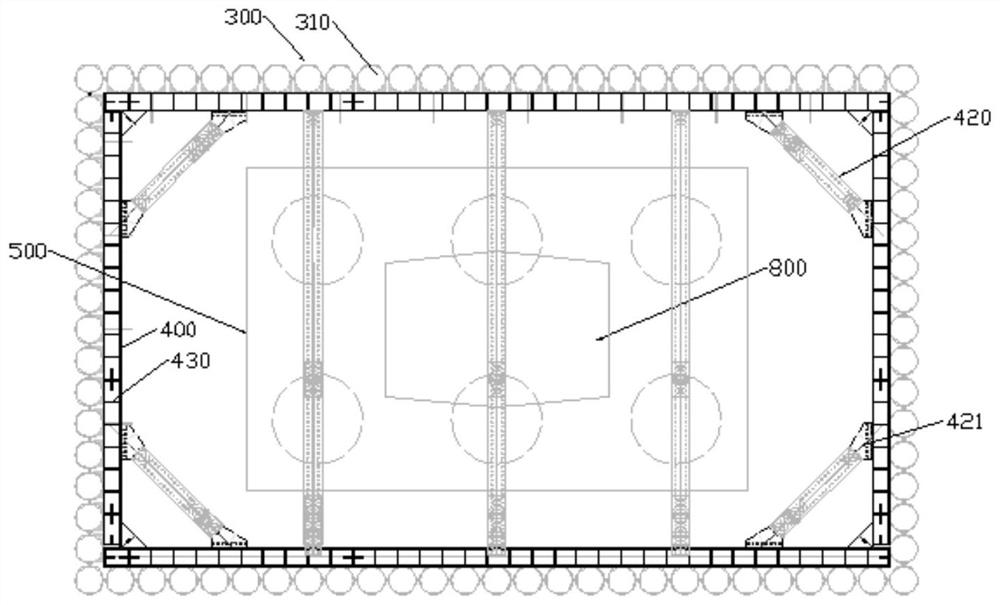

[0041] Such as Figure 1-Figure 9 As shown, the present invention provides a kind of locking steel pipe pile cofferdam construction method applicable to thin overburden hard riverbed, comprising the following steps:

[0042] Set up a working steel platform 100 and a trestle bridge 110 above the water surface, and then carry out measurement and stakeout according to the size of the cofferdam.

[0043] The positioning guide plate 200 is set on the steel platform 100, the positioning guide plate 200 is placed between the steel platform 100 and the trestle 110, and the corners of the positioning guide plate 200 are spot welded for reinforcement, wherein the positioning guide plate 200 is provided with a circular The guide cavity 240, and the circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com