Pressure control communication oil jacket annulus control valve

An oil casing annulus and pressure control technology, applied in the direction of wellbore/well valve devices, cleaning tools, wellbore/well components, etc., can solve the problems of equipment applications that cannot be opened or closed normally, cannot be opened or closed, etc. , to achieve the effects of preventing deposition, quick assembly, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with the accompanying drawings for further description:

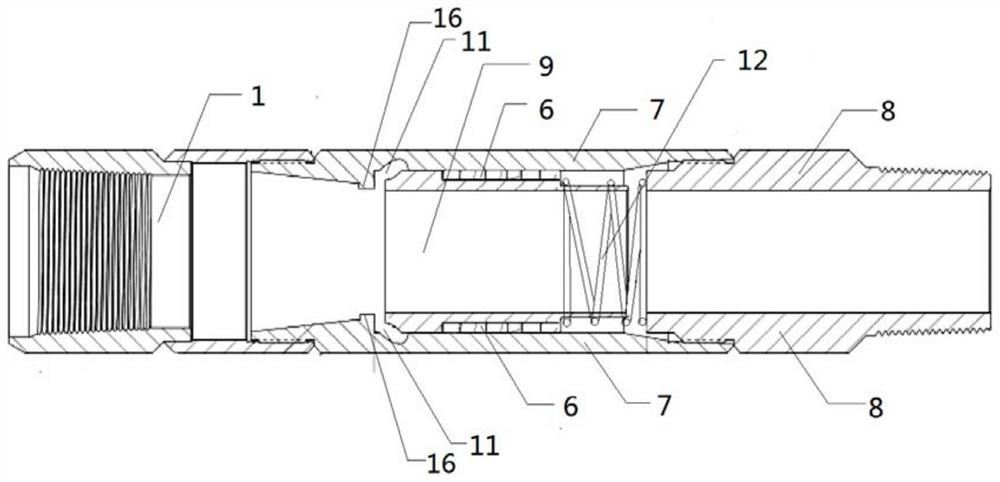

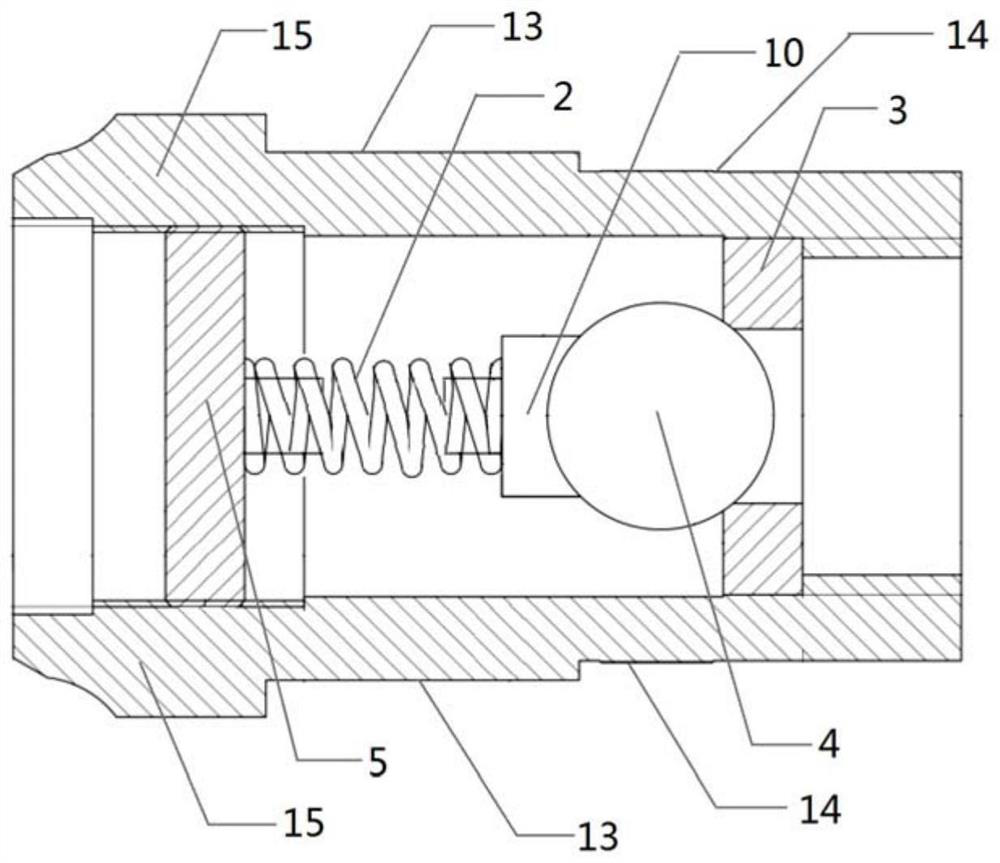

[0035] The embodiment of the present invention provides a pressure control communicating oil sleeve annulus control valve, such as figure 1 and figure 2 As shown, it includes upper joint 1, righting spring 2, sealing ball seat 3, sealing ball 4, positioning pin 5, sealing member 6, sealing shell 7, lower joint 8, sealing piston 9, spring top seat 10, oil discharge hole 11. Piston spring 12, necking step 13, end step 14 and piston housing 15;

[0036] The sealing piston 9 is composed of a piston housing 15, a necking step 13, an end step 14, a positioning pin 5, a centralizing spring 2, a spring top seat 10, a sealing ball 4, and a sealing ball seat 3; the sealing piston 9 is arranged in the sealing housing 7, the sealing member 6 is used to seal between the sealing piston 9 and the sealing housing 7, and the sealing piston 9 moves through the action of the piston spring 12;

[0037] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com