Diffractive optical element and optical equipment

A diffractive optical element and optical microstructure technology, applied in the field of optical diffraction, can solve the problems of large energy loss of diffracted optical signals and uneven energy distribution of diffracted optical signals, so as to improve the uniformity of energy distribution, reduce energy loss, and simplify boundaries. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

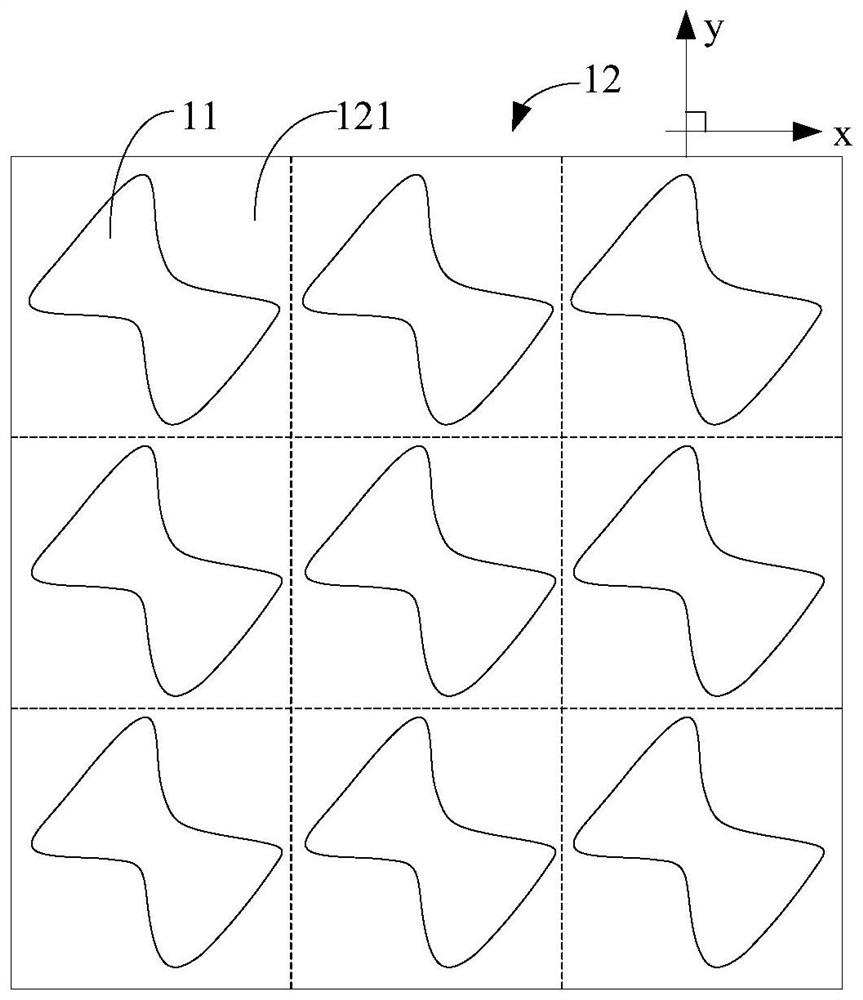

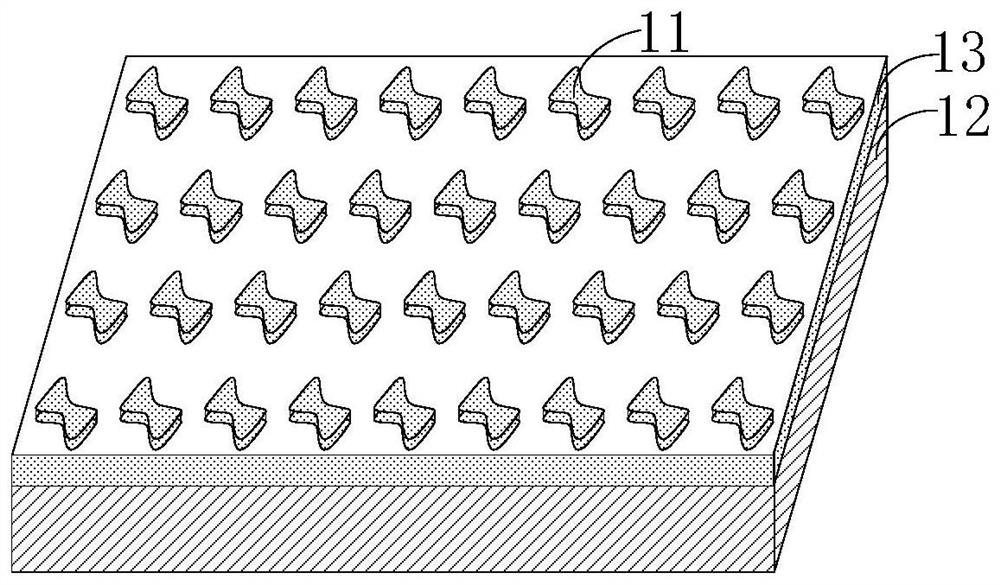

[0047] Such as figure 1 As shown, the embodiment of the present invention provides a diffractive optical element, which includes: a plurality of optical microstructures 11 and a substrate 12 .

[0048] Wherein, a plurality of rectangular setting areas 121 are arranged in an array on the substrate 12 ; the projection profile of each optical microstructure 11 along the direction perpendicular to the substrate 12 is located in the corresponding rectangular setting area 121 .

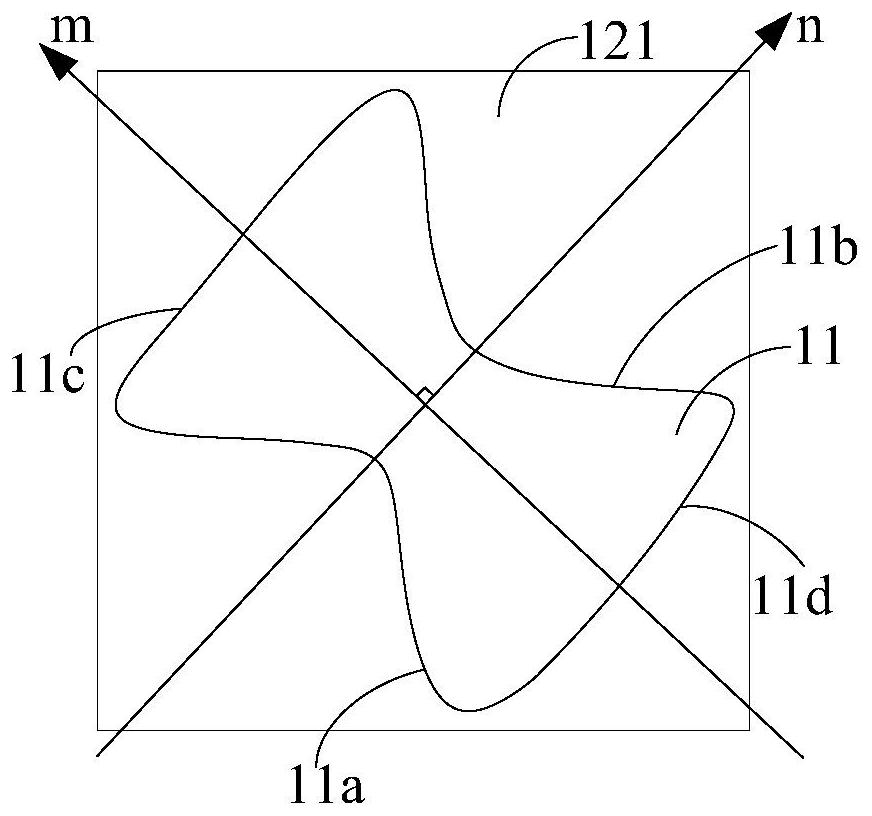

[0049] It should be noted that each optical microstructure 11 in the plurality of optical microstructures 11 is the same, and one of the optical microstructures 11 is taken as an example for illustration.

[0050] In the embodiment of the present invention, such as figure 2 As shown, the projected profile of each optical microstructure 11 includes a first boundary 11a and a second boundary 11b oppositely arranged along the first direction m, and the distance between the first boundary 11a and the second b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com