Liquefied natural gas transfer pipe for supplying fuel of ship engine

A technology for liquefied natural gas and fuel supply, which is applied in the direction of propulsion engine, ship propulsion, ship construction, etc., and can solve the problem of continuous deformation state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

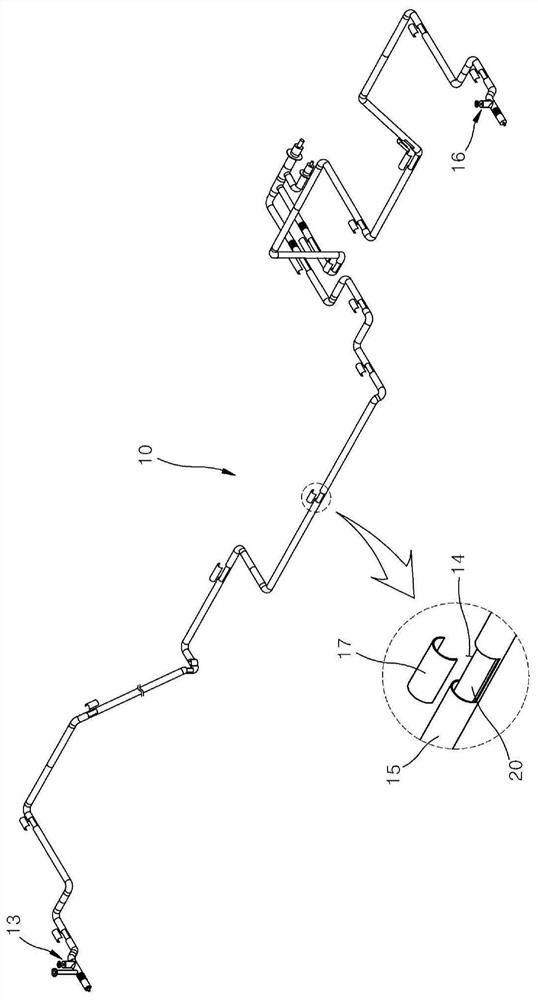

[0032] The liquefied natural gas delivery pipe for marine engine fuel supply according to the present invention can be applied to all paths or part of the path where liquefied natural gas moves from the storage tank of an LNG carrier fueled by liquefied natural gas to the marine engine, and can be used in various industries. Transportation of liquefied natural gas in facilities, hazardous areas.

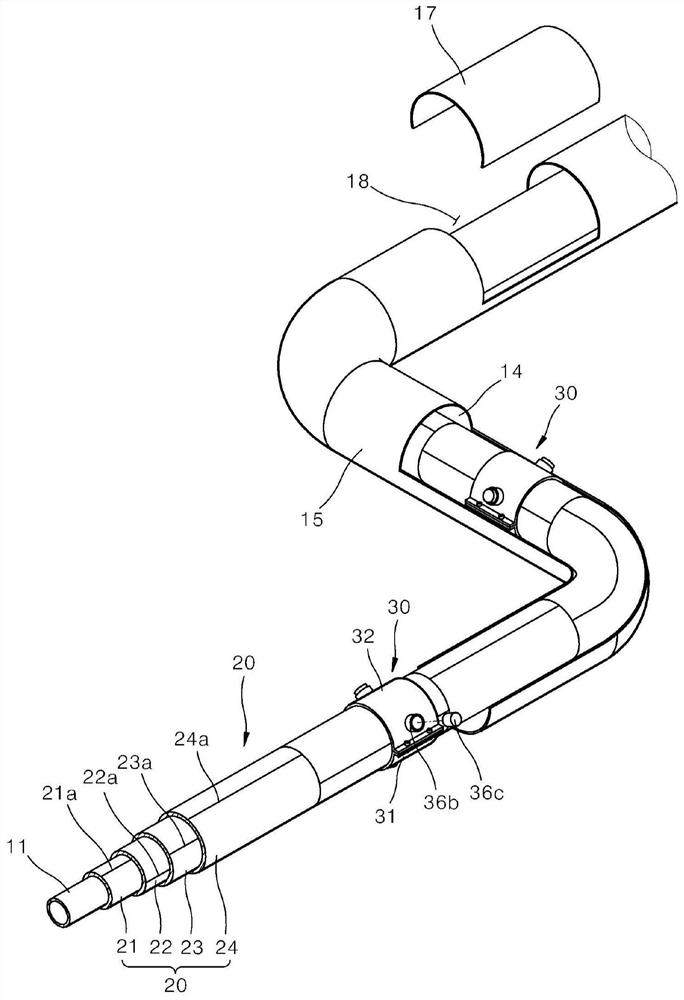

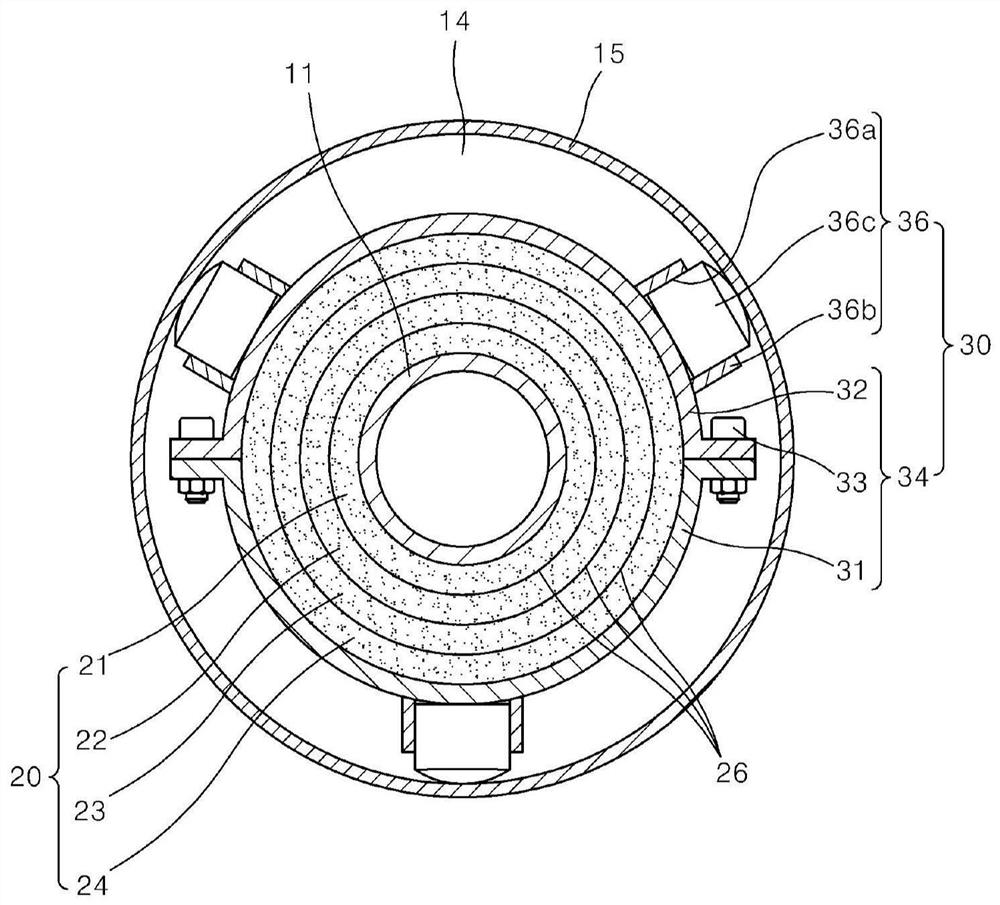

[0033] Figure 1 to Figure 3 A LNG delivery pipe for fuel supply of a marine engine according to an embodiment of the present invention is shown.

[0034] Referring to the accompanying drawings, the liquefied natural gas delivery pipe 10 for ship engine fuel supply is used to transport liquefied natural gas from the LNG fuel storage tank of the ship for LNG fuel transportation to the ship engine, which includes: an inner pipe 11, forming a flow path for the movement of liquefied natural gas; The heat insulating part 20 is formed to surround the outer peripheral surface of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com