Fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as high material load, machine pressure ratio and power density limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

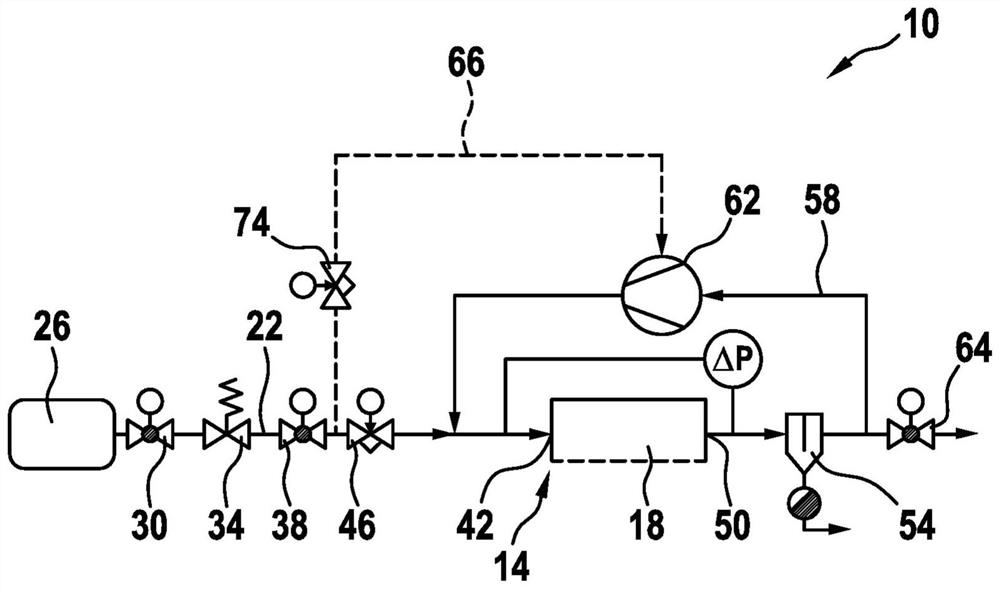

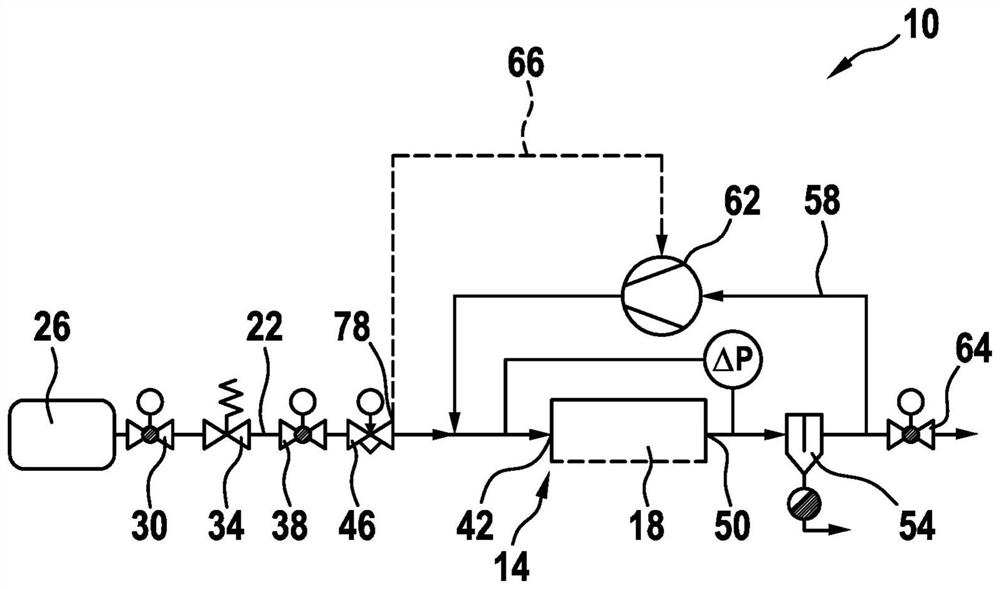

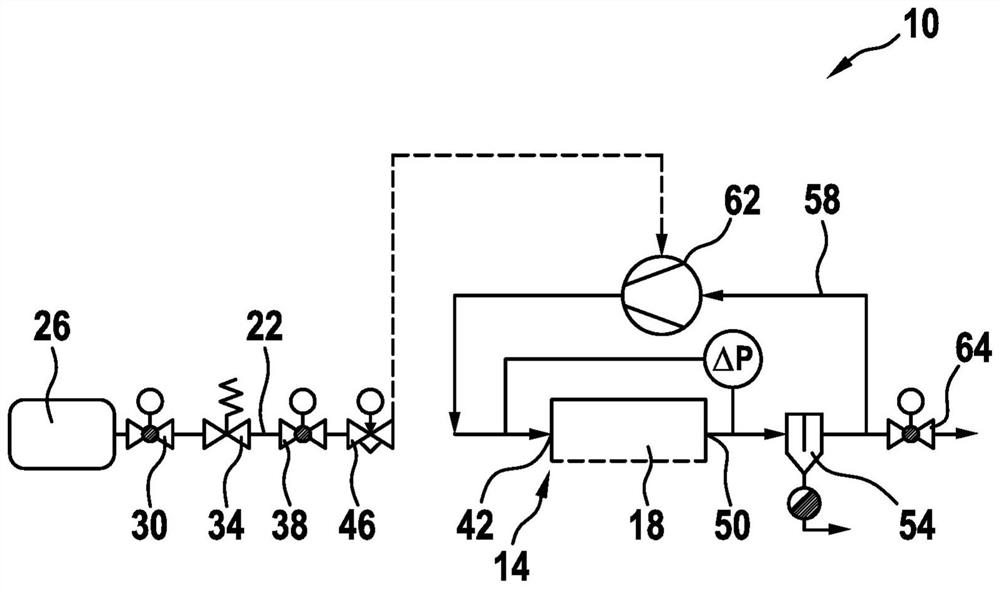

[0034] exist figure 1A first embodiment of a fuel cell system 10 according to the invention is shown in . The fuel cell system 10 here comprises a fuel cell 14 , of which only the anode space 18 is shown here. The anode chamber 18 is fluidically connected via a hydrogen supply line 22 to a hydrogen store 26 , which is here designed as a hydrogen tank. In the hydrogen supply line 22 , a tank shutoff valve 30 is arranged downstream of the hydrogen storage 26 in order to shut off the supply of hydrogen from the hydrogen storage 26 .

[0035] Downstream of the tank shut-off valve 30, a pressure reducer 34 is arranged in the hydrogen supply line 22 in order to bring the high pressure of the hydrogen storage 26 to a low pressure level. Downstream of this pressure reducer 34 , a low-pressure shut-off valve 38 is arranged in the hydrogen supply line 22 in order to interrupt the hydrogen supply in the low-pressure region. A hydrogen metering valve 46 is arranged between the low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com