Ultrasonic-assisted lost foam casting device for magnesium-aluminum bimetal casting and application

A lost foam casting and ultrasonic-assisted technology, applied in the field of metal casting manufacturing, can solve the problems of poor process stability of lost foam casting solid-liquid composite technology, and achieve the effects of reducing the heating rate, promoting the diffusion of elements, and refining the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

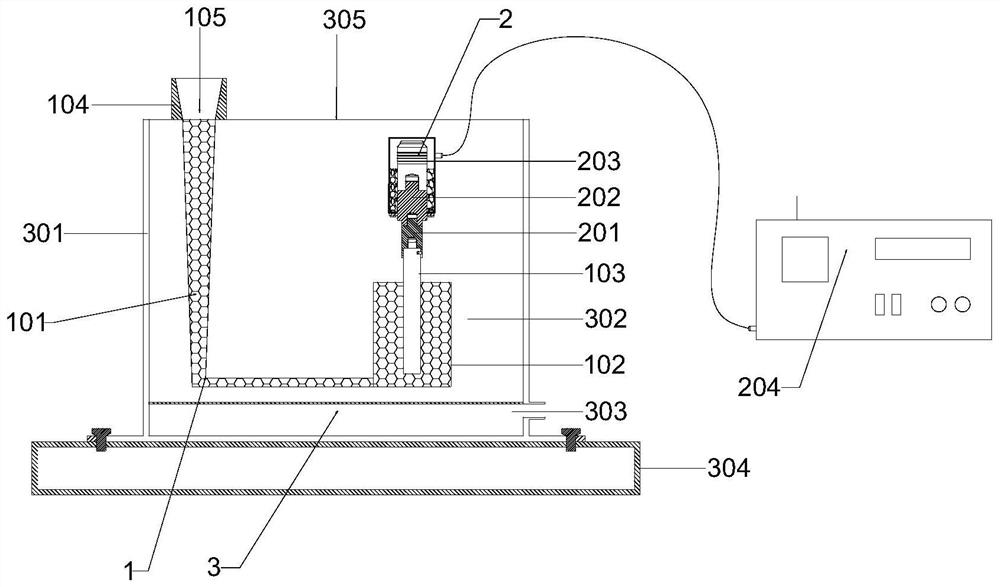

[0051] An apparatus for ultrasonically assisted lost foam casting of magnesium-aluminum bimetallic castings such as Figure 1-2 As shown, it includes a lost foam casting composite model 1, an ultrasonic vibration assembly 2 and a sand box 3. The lost foam casting composite model includes a gating system 101, a casting model 102 connected to the gating system 101, and a solid embedded casting model 102. Body 103;

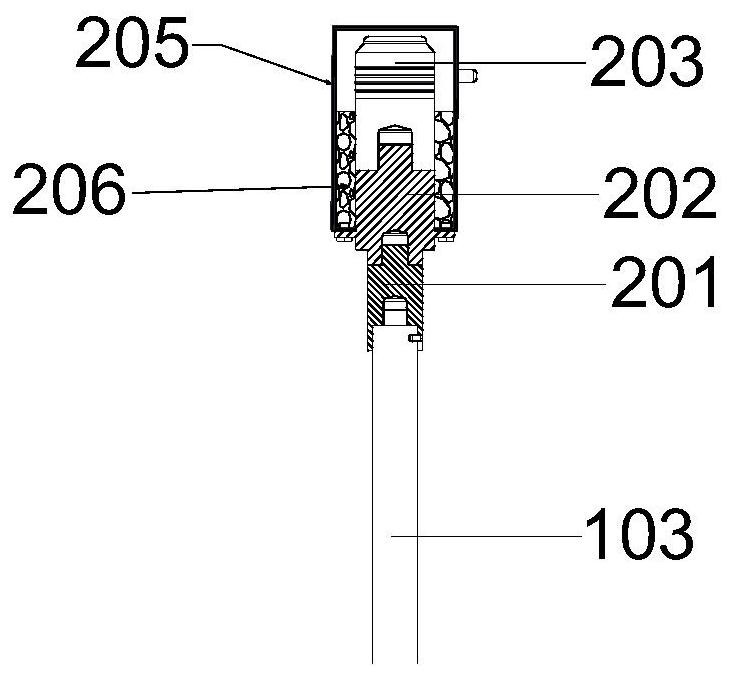

[0052] The ultrasonic vibration assembly 2 includes a connector 201, a transducer holder 202 detachably connected to the connector 201, an ultrasonic transducer 203 detachably connected to the transducer holder 202, and an ultrasonic transducer 203 An electrically connected ultrasonic generator 204, the connector 201 is fixedly connected to the solid inlay 103;

[0053] The sand box 3 includes a box body 301 and a vibrating table 304 located below the box body 301 , the composite model 1 and the ultrasonic vibration assembly 2 are located in the box body 301 and can...

Embodiment 2

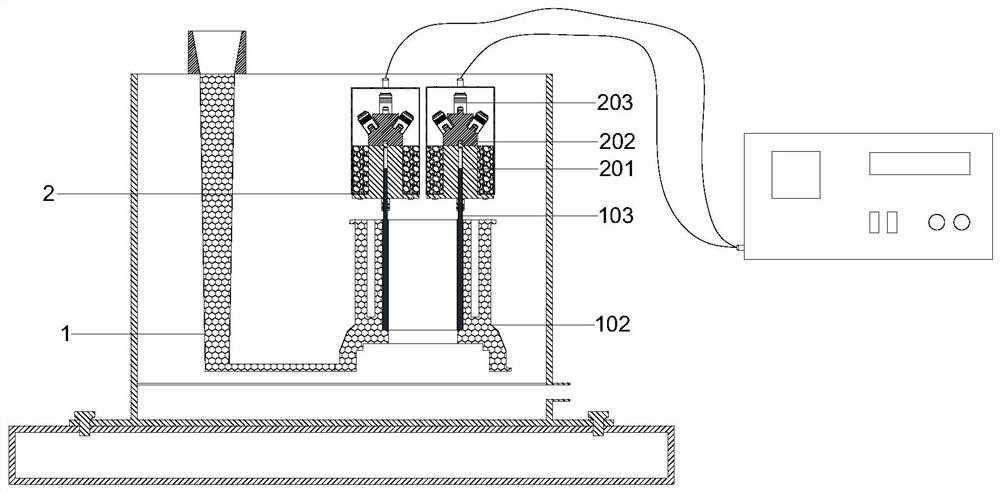

[0059] The difference between this embodiment and Embodiment 1 is that two ultrasonic vibration components 2 are provided, such as Figure 3-4 As shown, the solid inlay 103 is a geometric body with a regular shape, and a plurality of ultrasonic vibration components 2 are arranged symmetrically along the geometric body.

Embodiment 3

[0061] The difference between this embodiment and Embodiment 2 is that the ultrasonic generator 204 includes a master ultrasonic transducer 207 and two slave ultrasonic transducers 208, and the slave ultrasonic transducer 208 uses the master ultrasonic transducer The device 207 is arranged axisymmetrically. Preferably, the included angle between the slave ultrasonic transducer 208 and the master ultrasonic transducer 207 is 45-75°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com