Long-arm-span mechanical arm joint in large-magnetic-field high-vacuum strong-radiation environment

A radiation environment and high vacuum technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of open joints where radioactive substances are easy to reside, radiation pollutants are easy to reside, and the angle range is limited, achieving smooth and regular surfaces. Increase the range of activities and reduce the effect of staying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

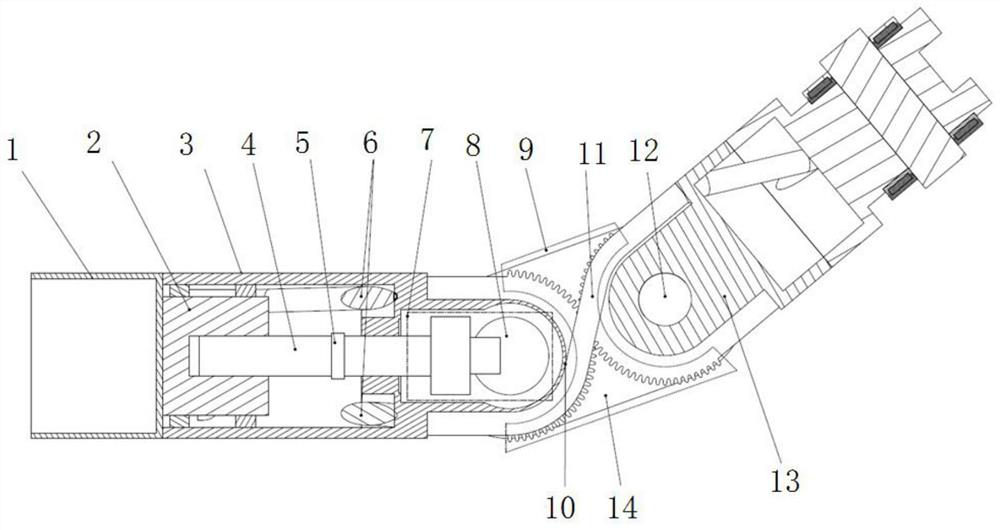

[0049] Such as figure 1 As shown, the mechanical arm joint includes the articulated arm driven part 13 connected to the shaft connecting plate 14 through the rotating shaft b12, and the active part of the articulated arm connected to the shaft connecting plate 14 through the rotating shaft a8;

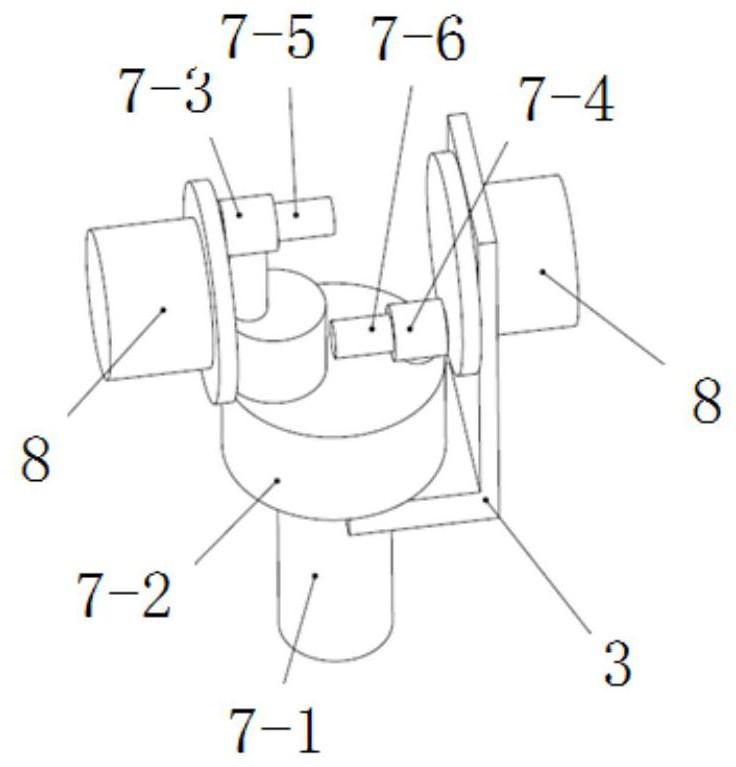

[0050] The active part includes a fully enclosed cavity 1 , a semi-closed cavity 3 , and a driver 2 installed in the semi-closed cavity 3 , a drive shaft 4 , a torque sensor 5 and a drive transmission system 7 . Wherein the driving transmission system 7 is connected with the shaft connecting plate 14 through the rotating shaft a8;

[0051] The drive shaft 4 is located on the axis of the active part. When the driver 2 drives the drive shaft 4 to rotate, the torque sensor 5 transmits the rotation data, and the drive shaft 4 rotates to drive the drive transmission system 7 connected to the end to rotate;

[0052] The pipelines and lines between the fully enclosed chamber 1 and the semi-e...

Embodiment 2

[0066] The driving transmission system 7 can also be a transmission mechanism composed of a pair of gears, the two gear shafts are perpendicular to each other, and the gears are a pair of meshing bevel gears or spiral bevel gears or straight bevel gears.

[0067] This structure is relatively simple, and the transmitted angle can be adjusted according to the transmission ratio of the gear pair, but the transmitted torque is not large. The main gear is installed on the driving shaft 7-1, and the auxiliary gear is installed on the rotating shaft a8. The rest are the same as in Example 1

Embodiment 3

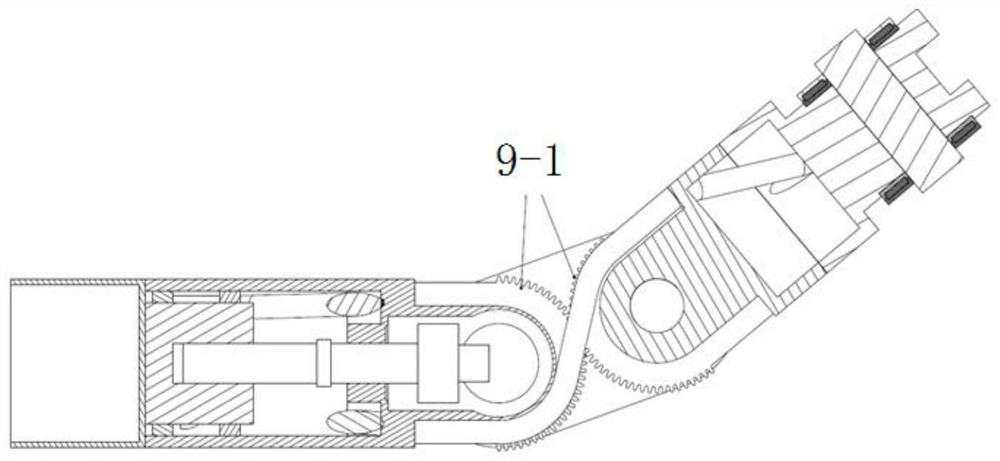

[0069] In this embodiment, the relevant structure of the drive transmission system 7 in the articulated arm is as follows:

[0070] Such as Figure 5 As shown, the main transmission shaft 7-21 is installed in the active mechanical arm 7-36 (which is equivalent to the cavity of the active part), and two internal main gears 7-22 and end internal gears 7-31 are installed on the main transmission shaft 7-21. , the vertical internal gear 7-23 and the inner end vertical gear 7-33 are installed on the inner wall of the active mechanical arm 7-36, and the external main gear 7-24 (equivalent to that of embodiment 1) is installed on the outer wall of the active mechanical arm 7-36. Two external meshing gears 9-1) and a connecting plate 7-27 (equivalent to the shaft connecting plate 14 in the embodiment), wherein the connecting plate 7-27 is installed through the rotating shaft a7-26 (equivalent to the rotating shaft a8), A sensor 7-34, which is an angle sensor or an angular velocity se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com