A core-shell type low-dielectric flame-resistant polyimide-based fiber material and its preparation method

A technology for burning polyimide-based and polyimide fibers is applied in the field of core-shell low-dielectric flame-retardant polyimide-based fiber materials and their preparation, and can solve the problem of aminopropyl-polysilsesquioxane The alkane raw materials are not easy to obtain, the flame retardant properties of the material are not considered, and it is difficult to develop and apply on a large scale, so as to achieve the effects of improving mechanical properties, reducing dielectric constant and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

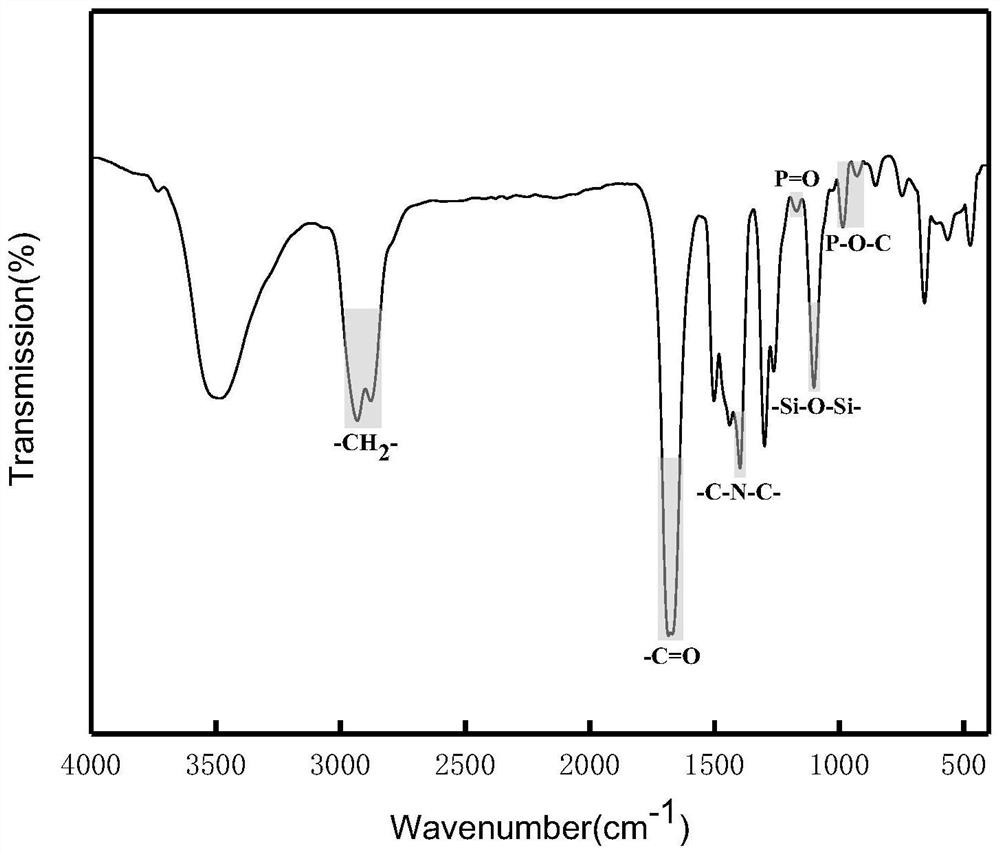

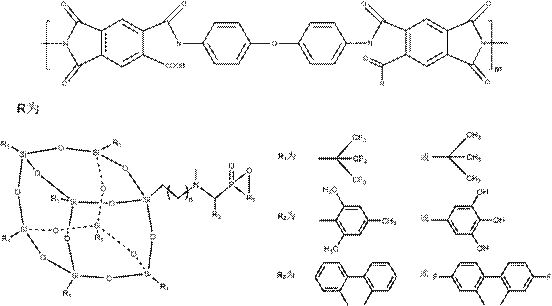

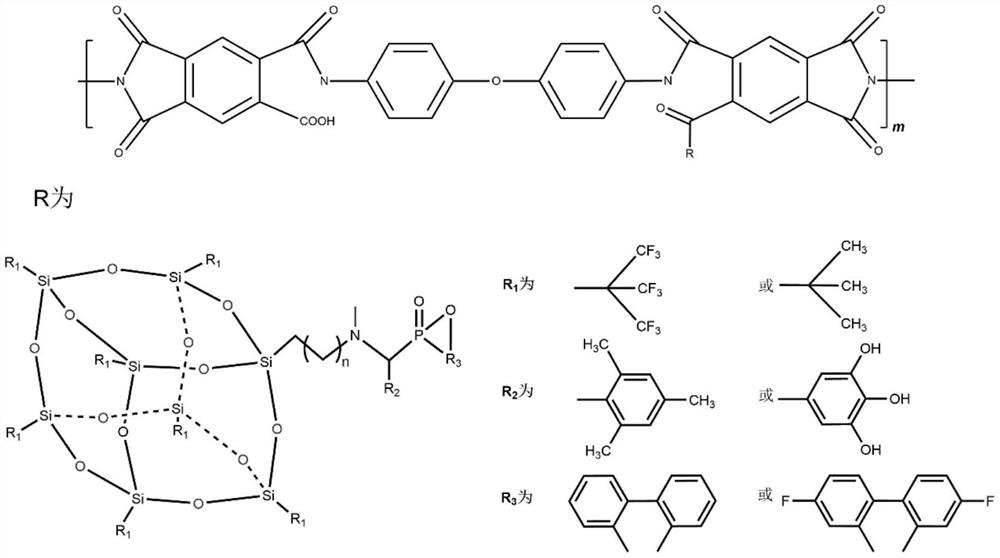

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a core-shell type low-dielectric flame-resistant polyimide-based fiber material is as follows:

[0045] a) At room temperature, N 2 Add 1.7g of aminoethylheptyl-polysilsesquioxane, 0.4g of 2,4,6-trimethylbenzaldehyde and 20g of acetone into the reaction kettle in an atmosphere, react at 55°C for 10h, then lower the temperature to 10°C, add 1.1g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 10g of absolute ethanol, mix well and add dropwise 15g of sodium carbonate solution (dissolved in 10mL of water ), after 0.5h of dripping, adjust the temperature to 55°C, react for 4h, distill under reduced pressure at 50°C for 0.5h, extract with 30mL of anhydrous methanol, wash with 60mL of petroleum ether for 3 times, and finally place it at 50°C for 20h , cooled to room temperature to obtain phosphate-based aminopolysilsesquioxane;

[0046] b) At room temperature, N 2 Add 1.0g of 4,4'-diaminodiphenyl ether, 8g of N,N-dimethylacetamide aromatic...

Embodiment 2

[0052] A preparation method of a core-shell type low-dielectric flame-resistant polyimide-based fiber material is as follows:

[0053] a) At room temperature, N 2 In the atmosphere, 2.8g of aminoethylfluoromethyl-polysilsesquioxane, 0.8g of 3,4,5-trihydroxybenzaldehyde and 40g of pentane were added to the reaction kettle, and reacted at 110°C for 4h, then the temperature Adjust to 25°C, then add 1.7g 3-fluoro-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 18g absolute ethanol, mix well and add dropwise 16g potassium carbonate solution (dissolved in 11mL of water), after 0.6h of dripping, adjust the temperature to 55°C, react for 10h, distill under reduced pressure at 55°C for 0.5h, extract with 45mL of anhydrous methanol, wash with 65mL of petroleum ether and filter three times, and finally Place it at 50°C for 14 hours, and cool to room temperature to prepare phosphate-based aminopolysilsesquioxane;

[0054] b) At room temperature, N 2 Add 1.2g of 4,4'-diaminodiphe...

Embodiment 3

[0060] A preparation method of a core-shell type low-dielectric flame-resistant polyimide-based fiber material is as follows:

[0061] a) At room temperature, N 2 In the atmosphere, 3.4g of aminopentylheptyl-polysilsesquioxane, 1g of 2,4,6-trimethylbenzaldehyde and 44g of chloroform were added to the reaction kettle, and reacted at 75°C for 8h, then the temperature Adjust to 15°C, add 2.3g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 20g of absolute ethanol, mix well and add dropwise 14g of sodium carbonate (dissolved in 11mL of water ), after 1 hour of dripping, adjust the temperature to 60°C, react for 6 hours, distill under reduced pressure at 55°C for 0.8h, extract with 70mL of anhydrous methanol, wash with 90mL of petroleum ether for 3 times, and place at 55°C for 18 hours , cooled to room temperature to obtain phosphate-based aminopolysilsesquioxane;

[0062] b) At room temperature, N 2 In the atmosphere, add 1.2g 4,4'-diaminodiphenyl ether, 10g N,N-dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com