A valve used in regenerative oxidation furnace rto

An oxidation furnace, regenerative technology, applied in valve heating/cooling devices, valve devices, valve details, etc., can solve the problems of difficult to guarantee the sealing performance of seals, low service life of switch control mechanisms, etc., to improve the use of Longevity, good sealing performance, tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

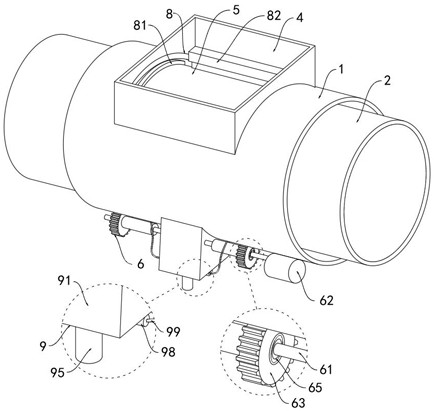

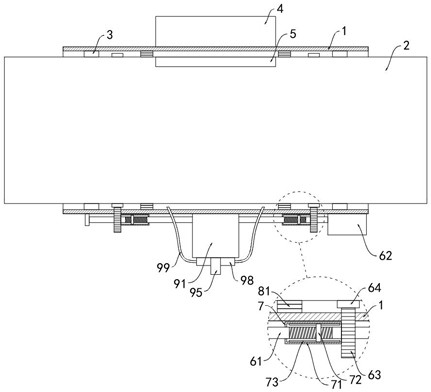

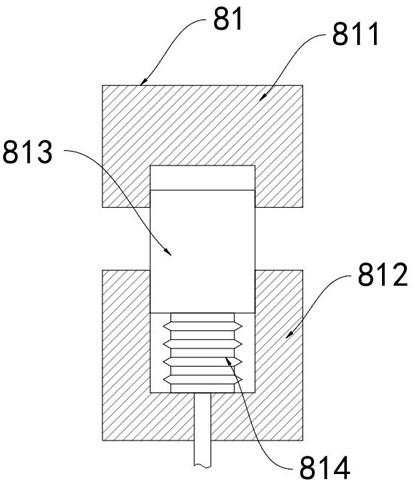

[0028] Such as Figure 1-5 As shown, a valve for regenerative oxidation furnace RTO includes a valve body 1 and a valve core 2, the valve body 1 and the valve core 2 are coaxially sleeved, and both are cylindrical structures, the valve body 1 and the valve core 2 are rotationally connected by a bearing 3, a connecting pipe 4 is provided on the valve body 1, an air outlet 5 matching the connecting pipe 4 is provided on the valve core 2, and a drive adjustment mechanism 6 is provided on the outer wall of the valve body 1.

[0029] Further, the drive adjustment mechanism 6 includes a rotating shaft 61 extending along the axial direction of the valve body 1. A driving motor 62 is installed on the outer wall of the valve body 1. The output end of the driving motor 62 is connected to the rotating shaft 61 through a coupling. On the rotating shaft 61 Two gears 63 are fixedly connected, and a gear ring 64 is coaxially sleeved on the outer wall of the valve core 2, and a through groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com