Heating wire driving circuit and electronic equipment

A driving circuit and heating wire technology, which is applied in ohmic resistance heating circuit diagrams, electrical components, electric heating devices, etc., can solve problems such as high cost, low control cycle, and low precision of triangular wave generators, so as to improve output accuracy and avoid conduction Resistance, the effect of improving current accuracy and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

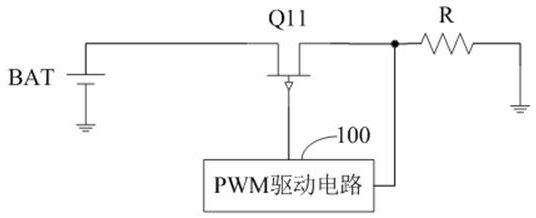

[0038] Such as image 3 as shown, image 3 The first structure schematic diagram of the heating wire driving circuit provided by the embodiment of the present invention, the heating wire driving circuit includes a battery BAT, a MOS transistor Q11 and a PWM driving circuit 100, the battery BAT, the MOS transistor Q11 and the heating wire R are connected in sequence, and the PWM drives The circuit 100 is connected to the gate and the output terminal of the MOS transistor Q11 respectively.

[0039]Wherein, the power terminal of the battery BAT is connected to the input terminal of the MOS transistor Q11 to provide driving power, the PWM driving circuit 100 obtains the terminal voltage of the heating wire R and converts and outputs the PWM signal to the MOS transistor Q11, and the MOS transistor Q11 corresponds to the PWM signal Turn on, and convert and output the required voltage and current to the heating wire R to achieve constant power output. The PWM drive circuit 100 perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com