Milky cosmetic

A technology for cosmetics and white turbidity, applied in the directions of cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of difficult emulsification, low compatibility, difficulty in white turbid cosmetics, etc., and achieve the effect of excellent stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

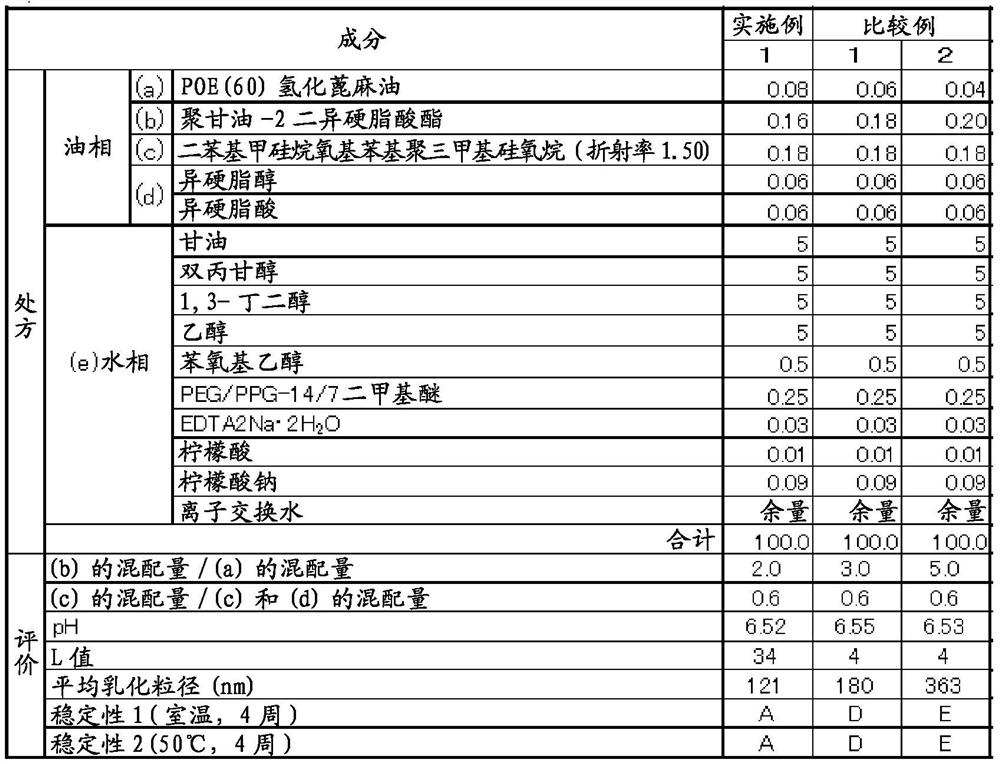

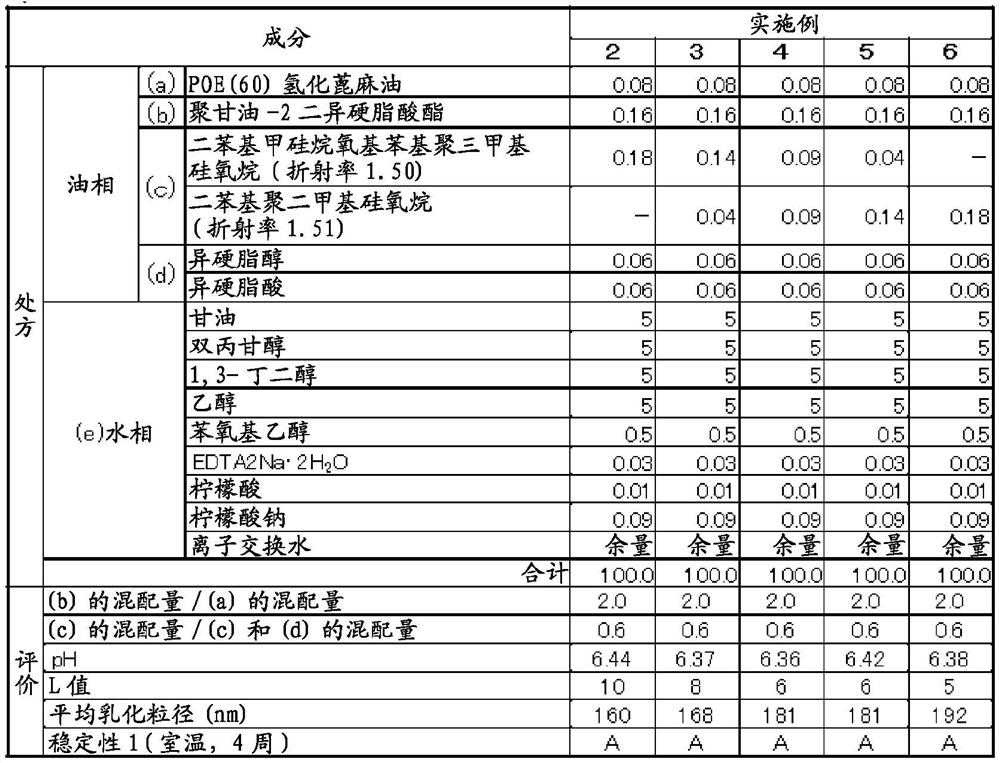

[0123] In Example 1, compared with Comparative Examples 1 and 2, the total amount of ingredients (a) and (b) is the same, but only the ratio of the amount of ingredients is different. As shown in Table 1, the average emulsified particle size of the cosmetics was in the range of 0.1 to 0.5 μm, and the L value was less than 60, and the white turbidity occurred. However, the cosmetics of Example 1 ((b) / (a)=2.0) were very excellent in stability over time at room temperature and high temperature, whereas the cosmetics of Comparative Examples 1 and 2 ((b) / (a) =3.0, 5.0) are poor in stability over time at both room temperature and high temperature.

[0124] Therefore, it was shown that (c) 60% by mass of silicone oil having a refractive index of 1.40 or more is contained (in the oil component), and if (a) polyoxyethylene hydrogenated castor oil and (b) polyglycerin-2 diisohard When fatty acid ester is emulsified by combining (b) in the compounding quantity ratio with respect to (a) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com