Flat wire motor, power assembly and vehicle

A flat wire and lead wire technology, applied in the shape/style/structure of winding insulation and the shape/style/structure of winding conductor, etc., can solve the problems of difficult potential balance, temperature rise and circulating current generation in three-phase branches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The proper nouns that appear in this application are explained below:

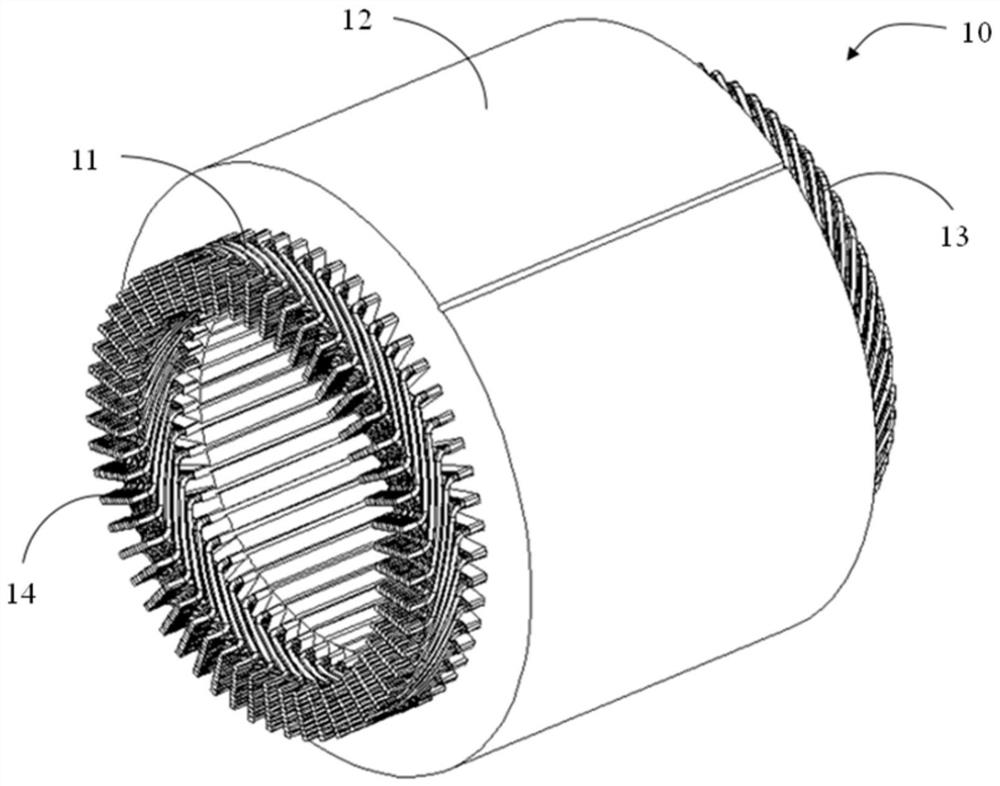

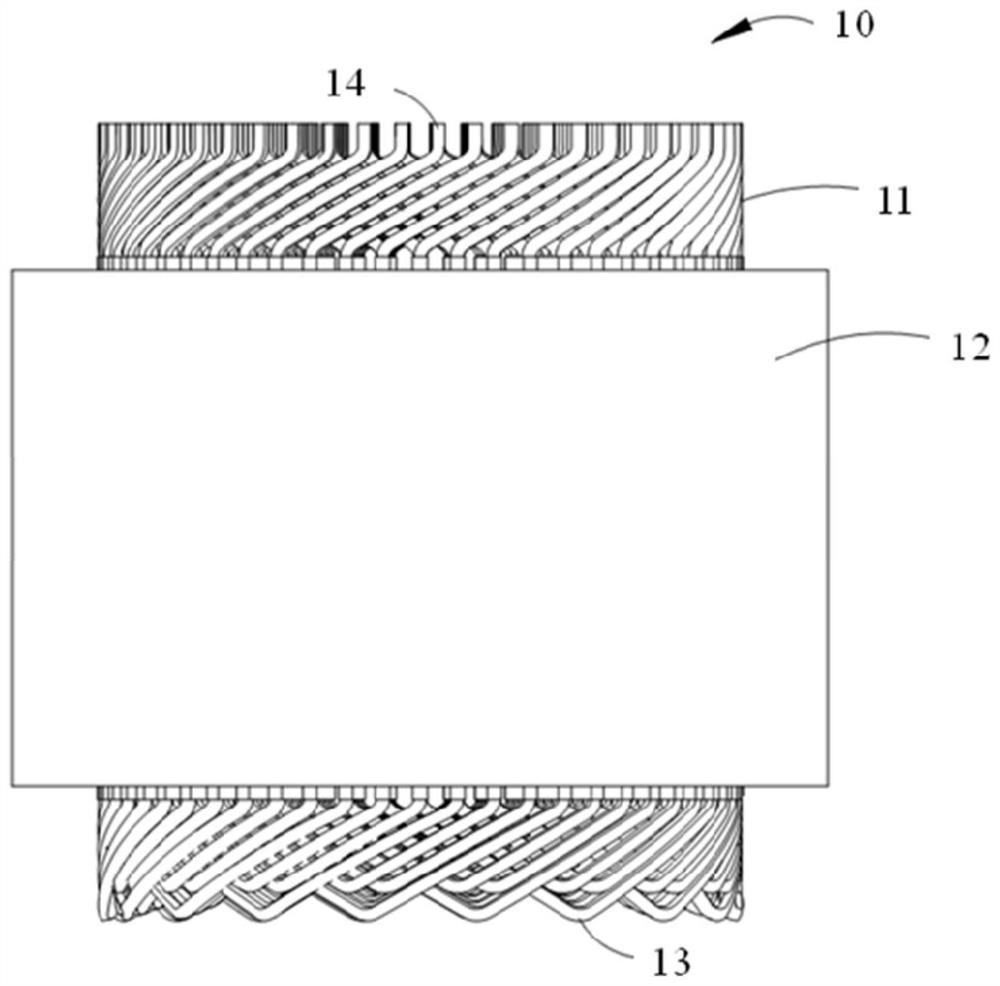

[0042] Stator: refers to the stationary part of the motor, whose function is to generate a rotating magnetic field.

[0043] Rotor: refers to the rotating part in the motor, which is used to realize the conversion of electrical energy and mechanical energy.

[0044] Motor circulation: It is the short-circuit current between two adjacent conductors in the motor caused by internal insulation aging, inter-turn short circuit and interlayer breakdown.

[0045] AC copper loss: It consists of two parts: basic copper loss and additional copper loss. The basic copper loss refers to the loss caused by the current flowing through the stator and rotor on the wire resistance; the additional copper loss is the additional loss caused by the skin effect and proximity effect of the alternating current on the stator and the circulating current between the stator strands caused by stray copper losses.

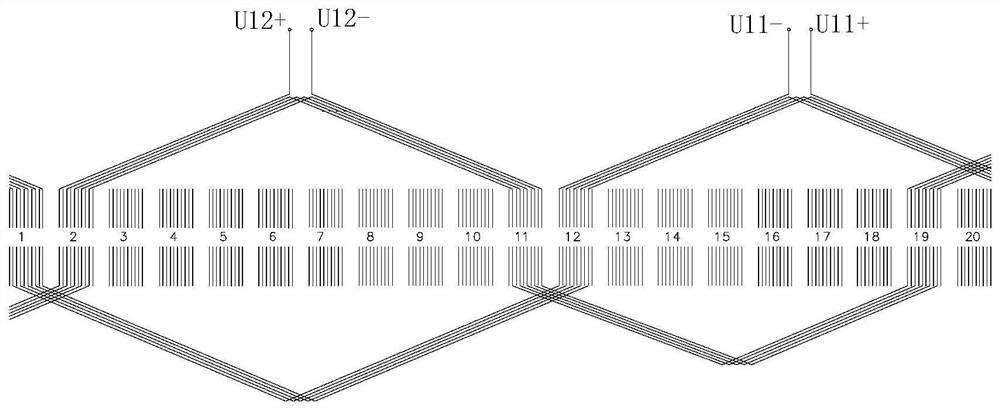

[0046] Span...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com