Decoction processing technology of black plaster for treating osteoarthropathy

A processing technology and osteoarthritis technology, applied in the field of black plaster, can solve the problems of lower product quality, singleness, and only one decoction, so as to improve the mixing degree, facilitate the thorough cleaning work, and avoid the effect of easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

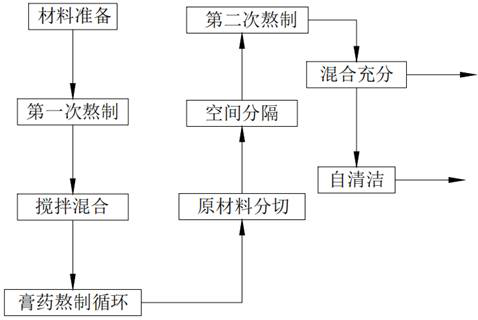

[0082] like figure 1 Shown, a kind of black plaster processing technology for the treatment of osteoarthropathy comprises:

[0083] Step 1, material preparation, placing the raw material in the loading assembly 31 of the carrying mechanism 3, then starting the first driving assembly 33 and the second driving assembly 34, and the third connecting column 331 of the loading assembly 31 goes down vertically Move and rotate, the filter cartridge 311 of the loading assembly 31 settles to the lower layer of the brewing box 1;

[0084] Step 2, boiling for the first time, the water pipe 62 of the cleaning mechanism 6 passes water into the boiling box 1 from the water tank 61, and performs the first boiling plaster work;

[0085] Step 3, stirring and mixing, during the rotation of the filter cartridge 311, the gear ring 321 of the dispersing assembly 32 drives the driving rack 327 to move back and forth, and the driving rack 327 utilizes the top support block b32b on the second connect...

Embodiment 2

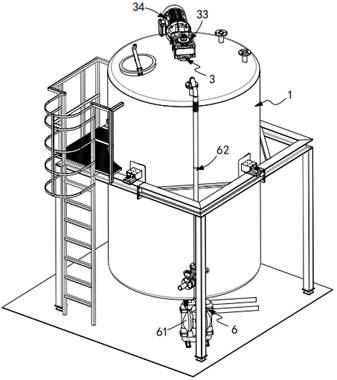

[0103] like figure 2 , image 3 As shown, a kind of pain relief plaster boiling equipment includes a boiling box 1 and a heater for heating the boiling box 1, and also includes:

[0104] The carrying mechanism 3, the carrying mechanism 3 is arranged on the boiling box 1 and moves up and down along the vertical direction of the boiling box 1, which includes a loading assembly 31 located in the boiling box 1, The dispersing assembly 32 for breaking up the medicinal materials in the loading assembly 31, the first driving assembly 33 arranged outside the brewing box 1 and used to drive the loading assembly 31 up and down, and the first driving assembly 33 for driving the loading assembly 31. The second driving assembly 34 that the object assembly 31 rotates;

[0105] The separation mechanism 4, which is located in the middle of the brewing box 1, includes a separation plate 41 and a seal that is synchronously driven with the first drive assembly 33 and is used to cooperate with...

Embodiment 3

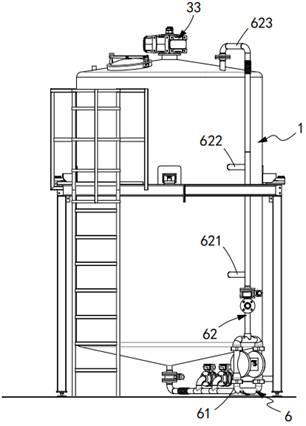

[0150] like image 3 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0151] further, such as image 3 As shown, the cleaning mechanism 6 includes a water tank 61 and a water pipe 62 with one end communicated with the water tank 61 and the other end communicated with the brewing tank 1. The water pipe 62 is provided with a first pipe 621, a second The secondary pipe 622 and the third pipe 623 .

[0152] In this embodiment, the cleaning mechanism 6 is provided to pass the output water into the brewing tank 1 for cleaning, thereby ensuring the cleanliness of the brewing tank 1 .

[0153] In detail, the first tube 621 is communicated with the lower layer of the brewing box 1; the second tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com