A stamping device for the preparation of hook-type commutators

A technology of stamping device and commutator, which is applied in the direction of commutator manufacturing, feeding device, positioning device, etc., can solve the problems of unfavorable continuous operation and difficult operation process, so as to reduce the difficulty of operation process and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

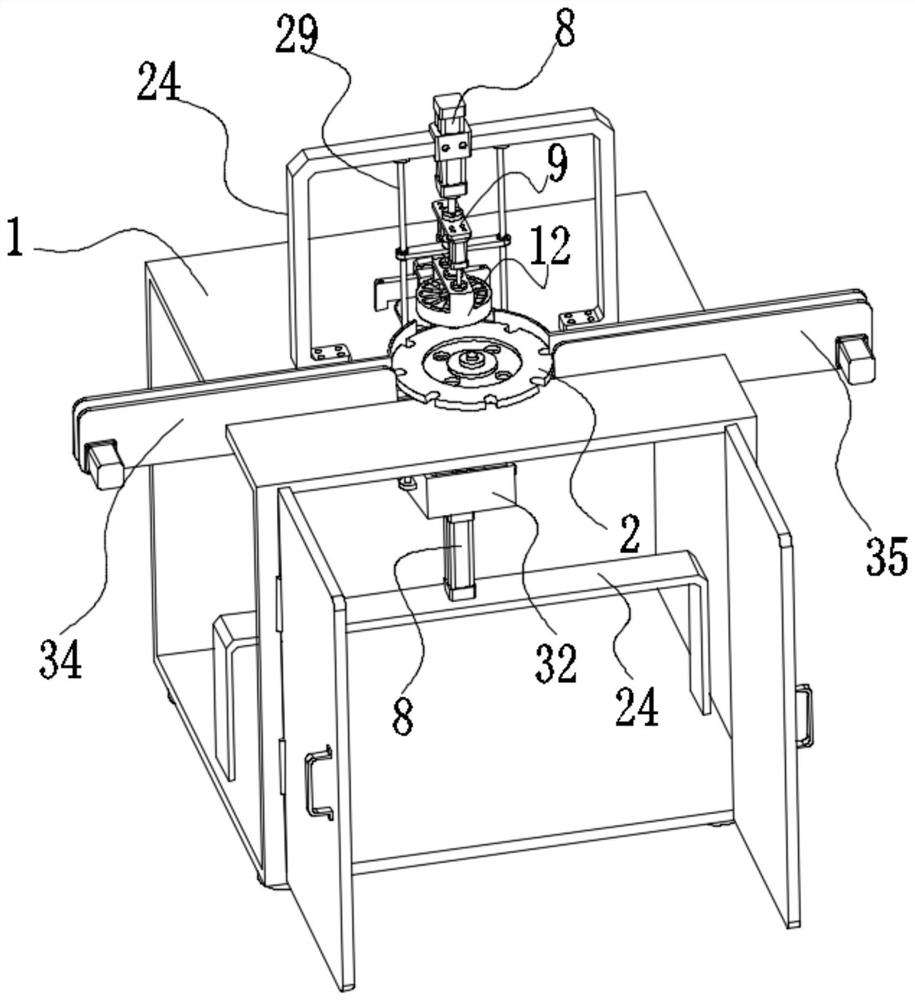

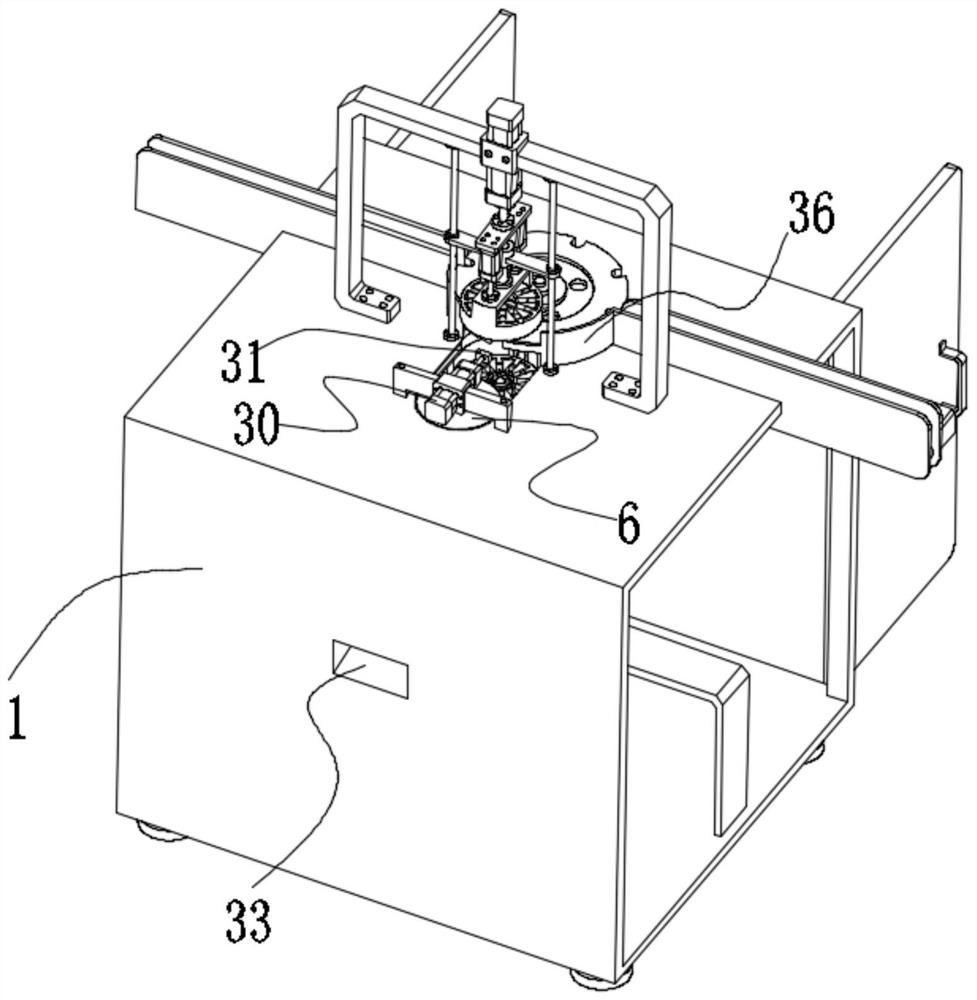

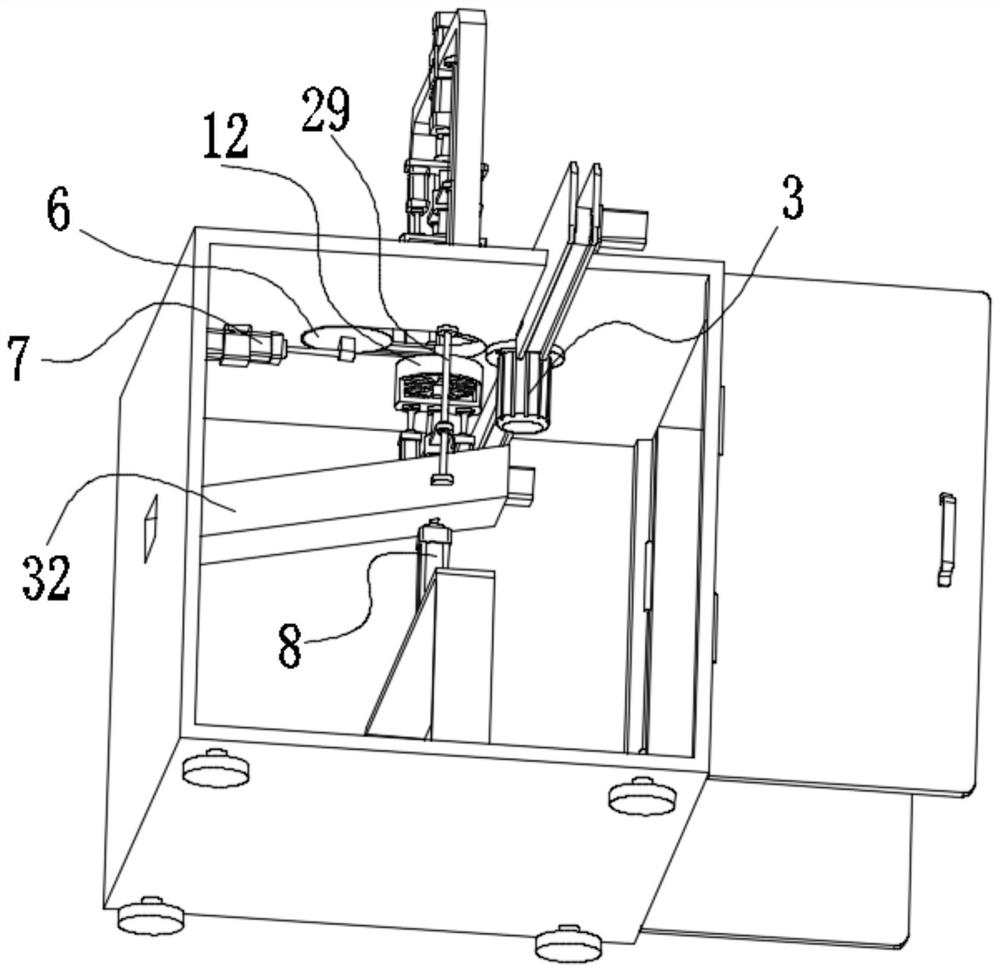

[0037] A punching device for the preparation of hook-type commutators in this embodiment, refer to Figure 1-8 : Including the body 1, the body 1 is a box with left and right transparent tempered glass and front side doors, and a waste port 33 connected to the waste tank 32 is opened at the rear side. Through the left and right transparent tempered glass, it is convenient to observe the internal work of the box. By setting the inclined waste slot 32 in the body 1, the punched waste will fall into the waste slot 32, and be removed from the waste slot 32. The waste port 33 is discharged; the top side of the body 1 is rotatably connected with a transfer member 2, and the transfer member 2 is a disc body with several groups of station ports 4 opened at equal angles. There is a certain gap between the bottom side of the body and the top side of the body 1 to ensure that the lower side punching mechanism can punch the lower end of the copper shell located in the station port 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com