Outer pipeline detection robot and walking method

A technology of robots and outer pipes, applied in instruments, motor vehicles, measuring devices, etc., can solve problems such as the inapplicability of crawling robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

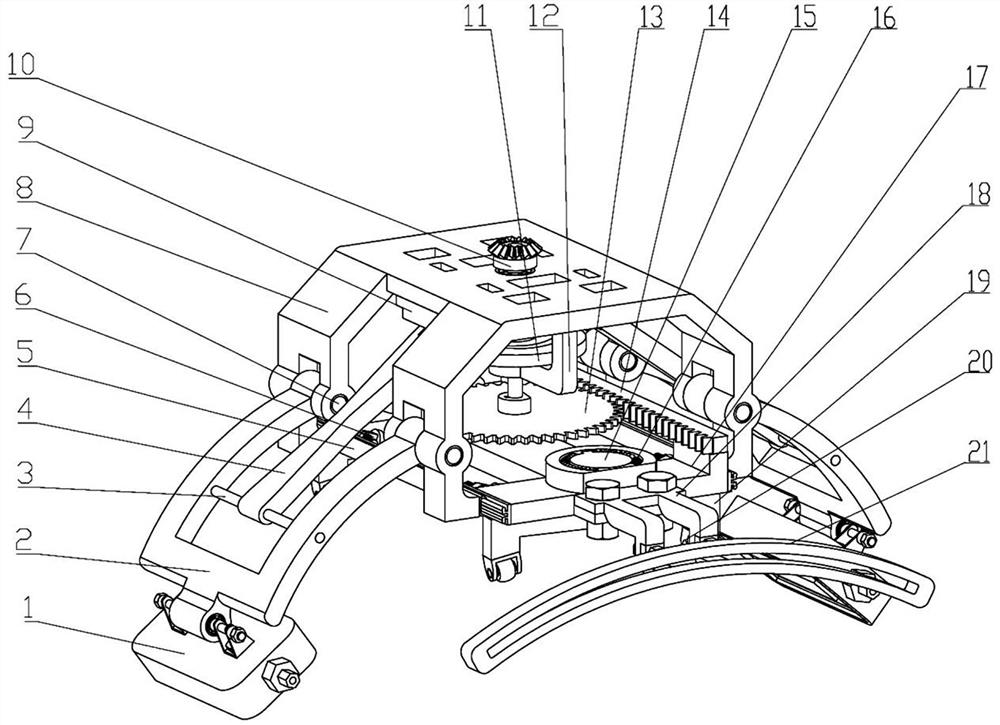

[0060] Such as Figure 1 to Figure 3 The shown outer pipeline detection robot includes an outer wall assembly and an inner wall assembly. Both the outer wall assembly and the inner wall assembly include a number of electronically controlled adsorption devices, which can be adsorbed on the outer wall of the pipeline to be detected; it also includes a main shaft 25, and The transmission assembly connected to the main shaft 25: when the main shaft 25 rotates forward, the transmission assembly drives the outer wall assembly forward, and drives the electronically controlled adsorption device on the outer wall assembly to alternately move closer to and away from the pipeline to be detected; when the main shaft 25 reverses, the transmission The assembly drives the inner wall assembly forward.

[0061] In this embodiment, the main shaft 25 is driven to rotate by a motor, and the output end of the motor can drive the bevel gear 10 to rotate by any existing method. When the motor rotat...

Embodiment 2

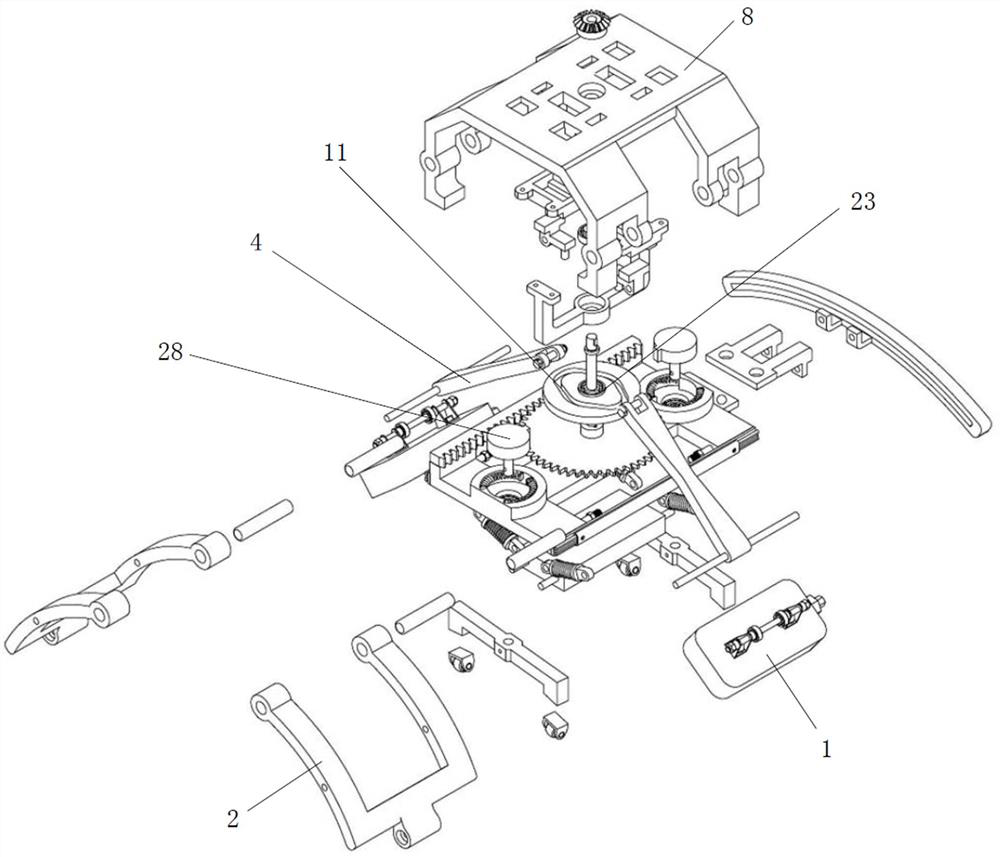

[0064] An outer pipeline detection robot, on the basis of embodiment 1, the outer wall assembly such as Figure 5 As shown, it includes two claw arms 2, and the claw arms 2 are arc-shaped with the concave surface downward; it also includes a connecting rod 4 that is rotationally connected with the claw arms 2, and the connecting rod 4 is used to connect with the transmission assembly; the electric control on the outer wall assembly The adsorption device is an outer wall electromagnet 1 hinged with a claw arm 2 . It also includes a casing 8; the claw arm 2 is hinged with the casing 8 through the connecting shaft 7, the main shaft 25 is rotatably connected with the casing 8 through a bearing 26, the claw arm 2 is fixedly connected to the connecting rod shaft 3, and the connecting rod 4 is rotatably connected to the connecting rod shaft 3 .

[0065] Transmission components such as Figure 4 As shown, it includes the gear 13 fixedly connected with the main shaft 25, the grooved ...

Embodiment 3

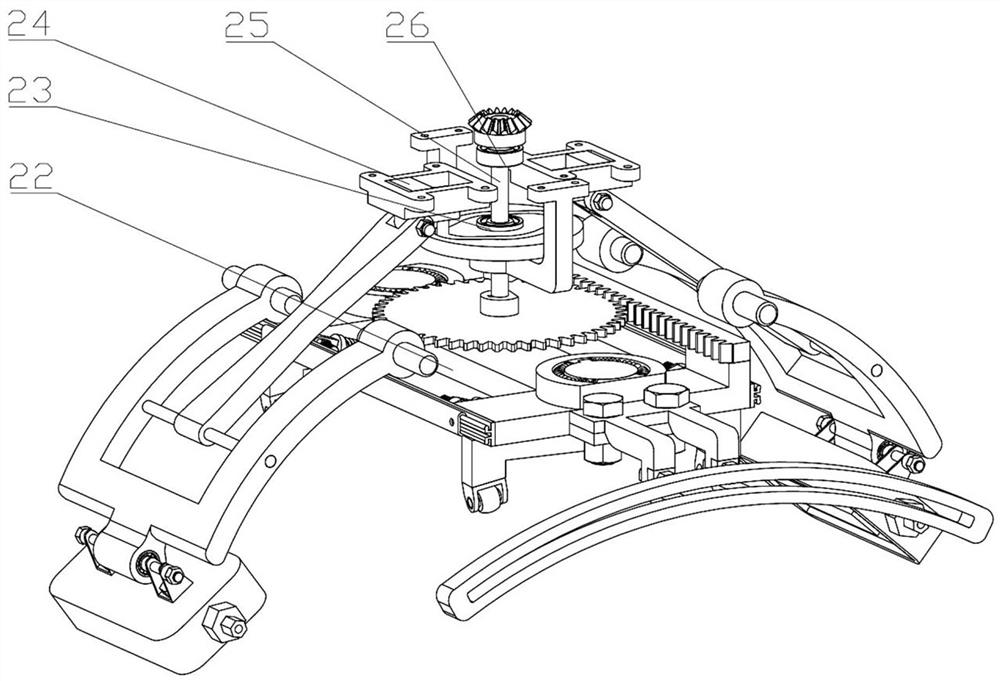

[0086] A kind of external pipe detection robot, on the basis of any one of the above-mentioned embodiments, such as figure 2 and Figure 7 As shown, the inner wall assembly includes an inner wall frame 17, two wheel frames 19 located on the side of the inner wall frame 17 facing the pipeline to be detected, and several guide wheels 20 located at the bottom of the wheel frame 19; also includes a steering assembly;

[0087] The steering assembly includes two circular grooves respectively located at the front and rear ends of the inner ledge 17, and a runner 28 located in the circular groove. The runner 28 is coaxial with the circular groove, and an annular gap 29 is formed between the runner 28 and the wall of the circular groove; The retainer 30 is fixed in the annular gap 29, the dial 15 located in the annular gap 29 is arranged on the runner 28, and the elastic member 16 located in the annular gap 29 is arranged between the retainer 30 and the dial 15; two runners 28 They a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com