Method for treating phenolic wastewater in high-concentration hydrochloric acid

A treatment method and technology for phenolic wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult wastewater treatment, high operating cost, and complicated process, and achieve The effect of the treatment effect is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

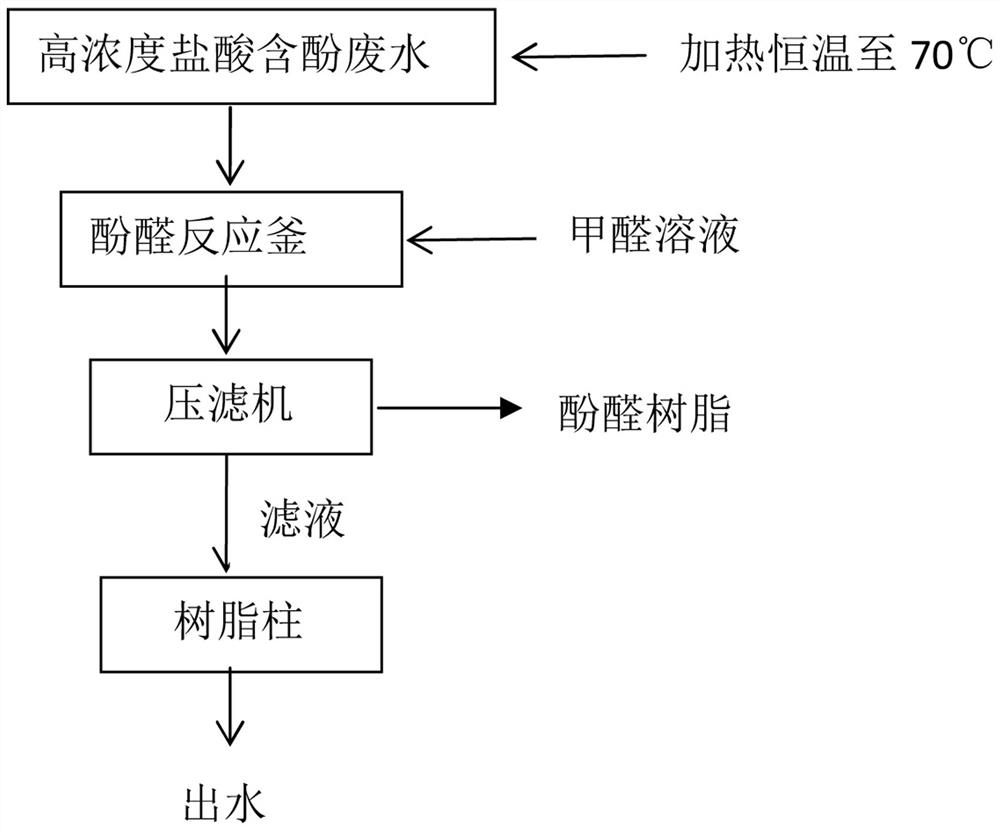

[0028] A chemical company produces wastewater in the process of producing ultraviolet absorbers. The content of hydrochloric acid is 20.5%, and the content of phenol is 300mg / L. This method is adopted for treatment. The specific treatment steps are as follows:

[0029] Step 1): Heating the waste water to 70°C, constant temperature,

[0030] Step 2): Dosing formaldehyde solution in the phenolic reaction kettle, the dosage is 1.1 times the mass of phenol in the wastewater, and the reaction lasts for 4 hours;

[0031] Step 3): Filter the product after the reaction in the previous step with a filter press.

[0032] Step 4): The filtrate after press filtration is treated with a resin column with a height-to-diameter ratio of 10:1 and an operating flow rate of 1.5BV / h.

[0033] After being treated by this method, the content of phenol in the terminal effluent is 0.5 mg / L, and the content of hydrochloric acid is 20.5%, and the hydrochloric acid can be recycled to production for reus...

Embodiment 2

[0035] A chemical company produces wastewater in the process of producing ultraviolet absorbers. The content of hydrochloric acid is 20%, and the content of phenol is 350mg / L. This method is adopted for treatment. The specific treatment steps are as follows:

[0036] Step 1): Heating the waste water to 70°C, constant temperature,

[0037] Step 2): Dosing formaldehyde solution in the phenolic reaction kettle, the dosage is 1.2 times the mass of phenol in the wastewater, and the reaction lasts for 4 hours;

[0038] Step 3): Filter the product after the reaction in the previous step with a filter press.

[0039] Step 4): The filtrate after press filtration is treated with a resin column with a height-to-diameter ratio of 10:1 and an operating flow rate of 1.5BV / h.

[0040] After being treated by this method, the content of phenol in the terminal effluent is 0.8 mg / L, and the content of hydrochloric acid is 20%, and the hydrochloric acid can be recycled to production for reuse. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com