Resin fiber and preparation method thereof

A resin fiber and fiber technology, applied in the field of resin fiber and its preparation, can solve the problems of low plugging efficiency, repetitive leakage, low pressure bearing capacity of plugging materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

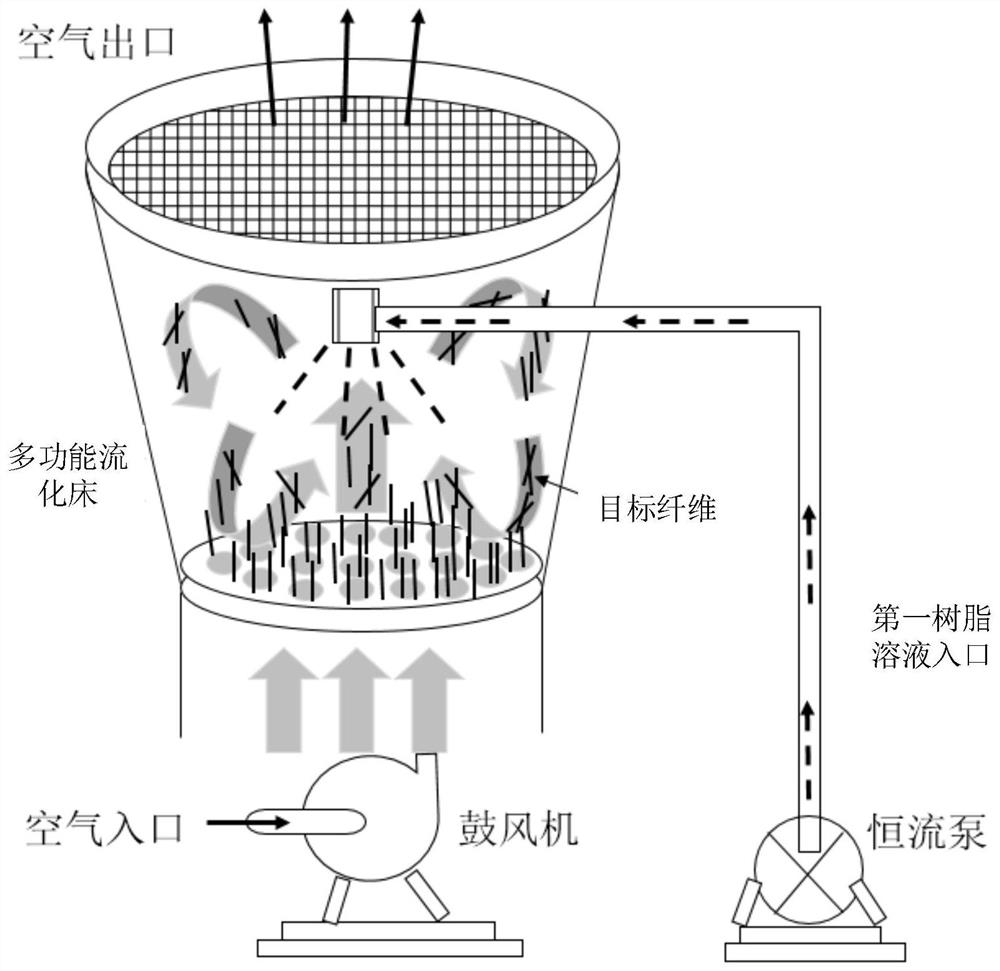

[0064] The embodiment of the present application provides a kind of preparation method of resin fiber, this method comprises:

[0065] Step 1: Put the target fiber into the multifunctional fluidized bed, start the blower, push and suspend the target fiber through the blower.

[0066] The blast speed of the blower is 40~80m 3 / h, the jet pressure is 0.4~0.6MPa, the air inlet temperature is 50~100℃, and the air outlet temperature is 40~80℃.

[0067] Step 2: Under the action of a constant-flow pump, spray the first resin solution on the target fibers with a high-pressure spray gun at a spray rate of 0.5-2 L / h, and dry for 2-6 hours to obtain the first fibers.

[0068] In this step, under the action of a constant flow pump, the first resin solution is atomized into fine droplets through a high-pressure spray gun, and sprayed at a spray rate of 0.5-2L / h on the target that is suspended and formed into a fluidized state due to the high-temperature airflow. On fibers, the intermitte...

Embodiment 1

[0079] In this embodiment, the mass ratio of the target fiber to the first resin solution is 1:0.098, the mass ratio of the target fiber to the second resin solution is 1:0.002, and the first resin solution includes: phenolic resin, epoxy resin and solvent .

[0080] Step 1: Put the basalt fiber with a length of 2-9 mm and a thickness of 0.3-0.8 mm into the multifunctional fluidized bed, start the blower, and push and suspend the basalt fiber through the blower.

[0081] The blower blowing speed is 80m 3 / h, the jet pressure is 0.4MPa, the air inlet temperature is 70°C, and the air outlet temperature is 70°C.

[0082] Step 2: Under the action of a constant flow pump, spray the first resin solution on the basalt fiber with a high-pressure spray gun at a spray rate of 1 L / h, and dry for 3 hours to obtain the first fiber.

[0083] Before this step, prepare the first resin solution. The preparation process of the first resin solution is: add the ethanol that mass percent is 62%...

Embodiment 2

[0087] In this embodiment, the mass ratio of the target fiber to the first resin solution is 1:0.286, the mass ratio of the target fiber to the second resin solution is 1:0.014, and the first resin solution includes: phenolic resin, epoxy resin and solvent .

[0088] Step 1: Put glass fibers with a length of 2-9 mm and a thickness of 0.3-0.8 mm into a multifunctional fluidized bed, start the blower, and push and suspend the glass fibers through the blower.

[0089] Blower blowing speed is 60m 3 / h, the jet pressure is 0.5MPa, the air inlet temperature is 100°C, and the air outlet temperature is 65°C.

[0090] Step 2: Under the action of a constant flow pump, spray the first resin solution on the glass fibers with a high-pressure spray gun at a spray rate of 2 L / h, and dry for 3.5 hours to obtain the first fibers.

[0091] Before this step, prepare the first resin solution. The preparation process of the first resin solution is: add the acetone that mass percentage is 50% in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com