Treatment method for hydraulic structure foundation

A treatment method and technology for structures, which are applied in construction, soil protection, infrastructure engineering, etc., can solve problems such as difficulty in guaranteeing the quality of the surface layer, and achieve the effect of improving the quality and strength of the surface layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

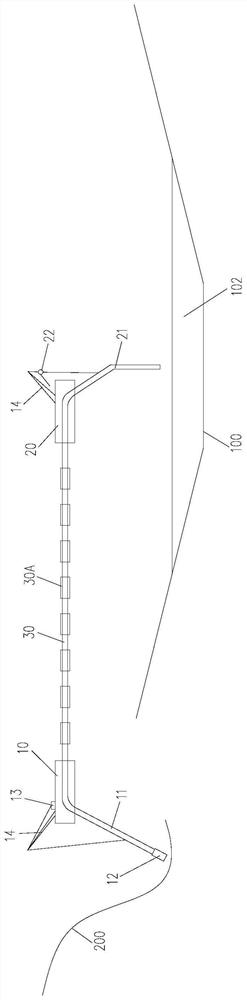

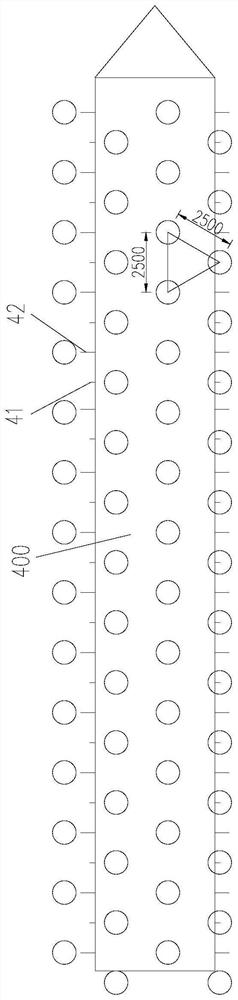

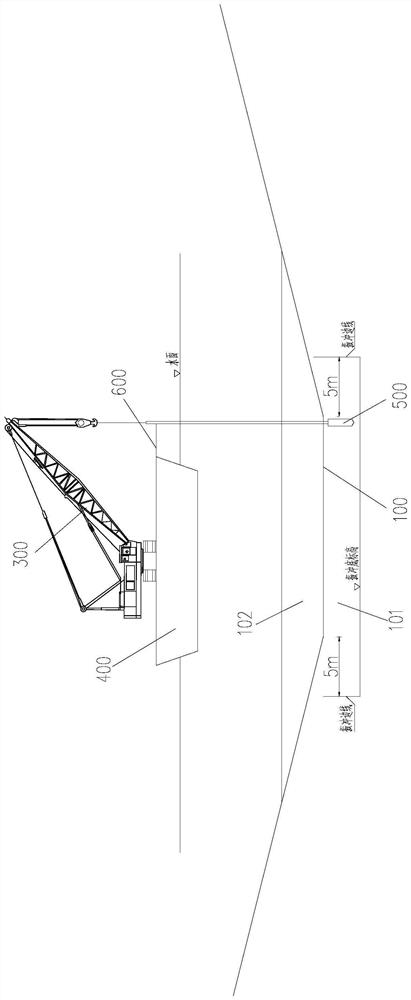

[0030] see Figure 1 to Figure 4 , the processing method of hydraulic structure foundation of the present invention, comprises the following steps:

[0031] Step 1: Excavate a foundation trench 100 at the installation position of the hydraulic structure on the seabed, leave 3m thick undisturbed sand 101 at the bottom of the foundation trench 100 without excavation, and conduct foundation trench acceptance according to the double control of elevation and bearing layer;

[0032] Step 2, blasting sand into the foundation groove (see figure 1 ), including the following steps:

[0033] Process 2.1, a sand pumping control platform 10 is fixed on the water surface next to the sand pile 200 on the bank through a figure-eight anchor, the front end of the sand pumping control platform 10 is hinged to a sand pumping pipe 11, and the front end of the sand pumping pipe 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com