Sampling method of sample for wire rod non-metallic inclusion inspection

A technology for non-metallic inclusions and metallographic samples, applied in the field of inspection of non-metallic inclusions in wire rods, can solve the problems of increasing wire inspection costs and low wire inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

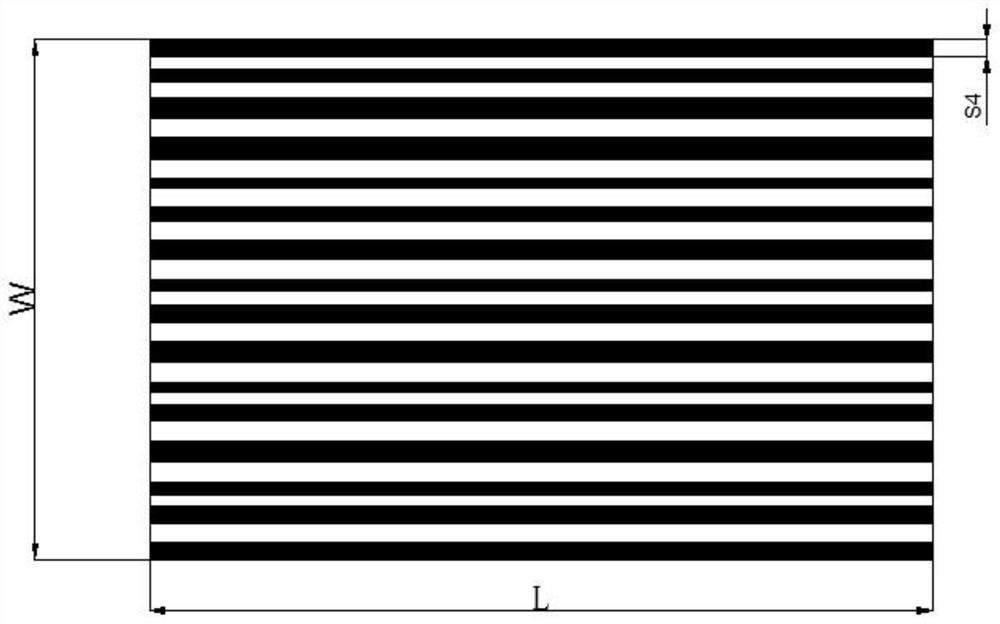

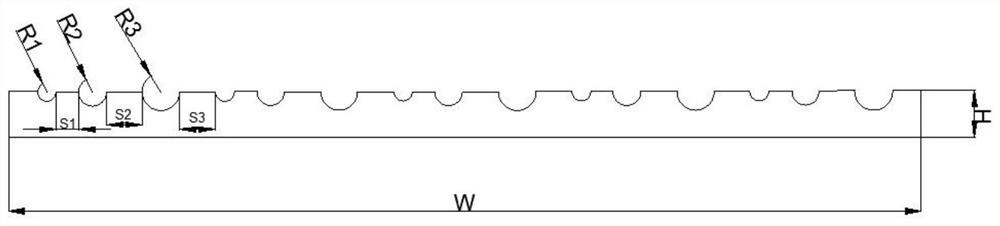

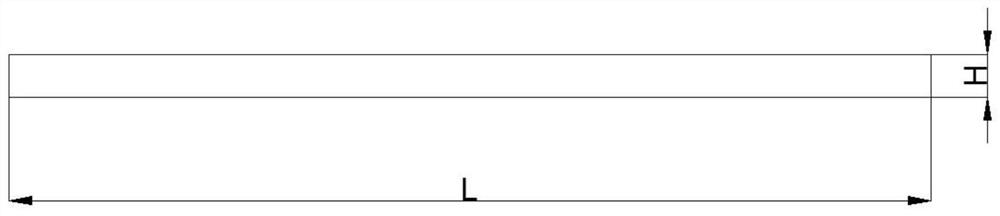

[0045] DETAILED DESCRIPTION one: one kind of a wire according to the present embodiment nonmetallic inclusions embodiment test sample sampling method to ≤6mm φ5.5mm≤ wire diameter wire, for example, according to the GB / T10561-2005 sample 3 "diameter or side length of less than 25mm of steel rod, through the entire testing side cross-sectional diameter, its length should give assurance about 200mm 2 Test area ", the first plurality of wire 40mm taken as a sample;

[0046] A plurality of sample was then placed on a magnetic chuck metal base, φ5.5mm≤ sample using DIAMETER ≤6mm radius R 1 The semi-cylindrical groove, the grinding dimensions of 2.75 ~ 3mm, per 30 samples can be mounted on the metal base segments, the use of 30 sample grinder for grinding segments need 40min, the processing time for a single sample period an average of about is 1.3min;

[0047] If the sampling method of the conventional sampling method, the grinding machine to wire cutting, the remaining steps unchang...

specific Embodiment approach 2

[0048] DETAILED DESCRIPTION two: one kind of a wire according to the present embodiment nonmetallic inclusions embodiment of sampling specimens for testing to φ6mm ≤8mm wire 2 The inspection area is therefore first takes a number of 30-35 mm wires as a sample;

[0049] The plurality of samples are placed on the metal base on the electromagnetic suction cup, φ6mm 2 The semi-cylindrical slot, the grinding size is 3-4 mm, 35 test sections per metal base, using grinding machines for 35 test segments to be worn for 50 min, and the processing time of single sample segment is about 3 1.4min;

[0050] If the sample method is the existing sampling method, the grinding machine is changed to the wire cutting process, the remaining steps are not changed, and the wire cutting of the wire diameter ≤ 8 mm is as an example. The line cutting length is 6-8 mm, the length of the sample section is 30 -35mm, each processing can be installed with a sample segment, each sample processing time of 18 min....

specific Embodiment approach 3

[0051] DETAILED DESCRIPTION OF THE INVENTION 3: Sampling method of a wire non-metal clamp detection sample according to the present embodiment, as an example of φ8 mm 2 The inspection area is therefore first takes a number of wires 20-25mm as a sample;

[0052] The plurality of samples are placed on the metal base on the electromagnetic suction cup, φ8mm 3 The semi-cylindrical slot, the grinding size is 4-5mm, 40 test segments per time on the metal base are installed, and 40 test segments are used to abrasive for 1 h, and the machining time of a single sample section is approximately. 1.5 min;

[0053] If the sample method is the existing sampling method, the grinding machine is changed to the wire cutting process, the remaining steps are not changed, and the wire is used as an example of φ8mm <wire diameter ≤ 10 mm, the line cut length is 8-10 mm, the length of the sample section is 25- 30mm, each processing can be installed with a sample, each of which is 18 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com