Method for detecting element enrichment on surface of plate steel base material

A technology for the surface of a substrate and a plate is applied in the field of detecting the enrichment of elements on the surface of a steel substrate of a plate, which can solve the problem that the enrichment of surface elements cannot be accurately detected, and achieve the effect of simple measurement method and accurate numerical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

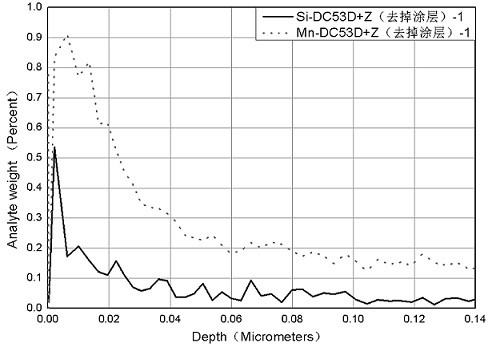

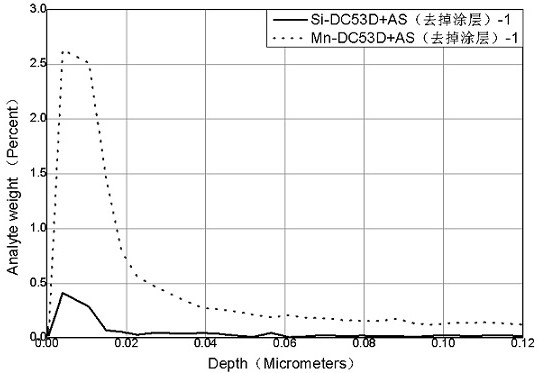

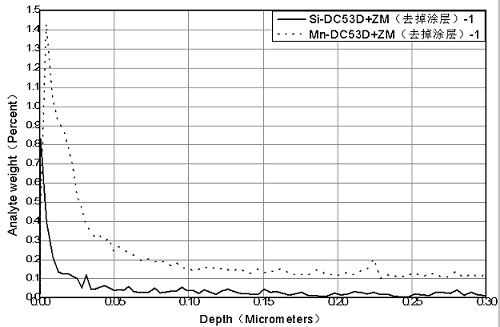

[0021] Examples 1-4 illustrate the method of the present invention by taking galvanized sheet, aluminum-coated sheet, and galvanized magnesium-aluminum sheet as examples, but this method is applicable to steel sheets with other coatings. The produced test plate is made into a disc with a diameter of 60mm-100mm (it can also be made into a square sample with a side length of 60mm-100mm). Before testing, the surface coating of the plate sample is dissolved and removed by chemical reagents. The dosage of hexamethylenetetramine and concentrated hydrochloric acid is shown in Table 1. After the preparation of the chemical reagents is completed, put the plate sample into the prepared chemical reagent for dissolving the coating. When the bubbles on the surface of the sample disappear during the dissolution process, immediately put the sample Take it out from the reagent, rinse the surface of the sample with a large amount of alcohol, and immediately dry the liquid on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com