Integrated optimization system for scheduling problem of distributed zero-latency flow shop

A workshop scheduling and distributed technology, applied in the direction of control/regulation system, general control system, comprehensive factory control, etc., can solve the problems of increasing complexity and lack of systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

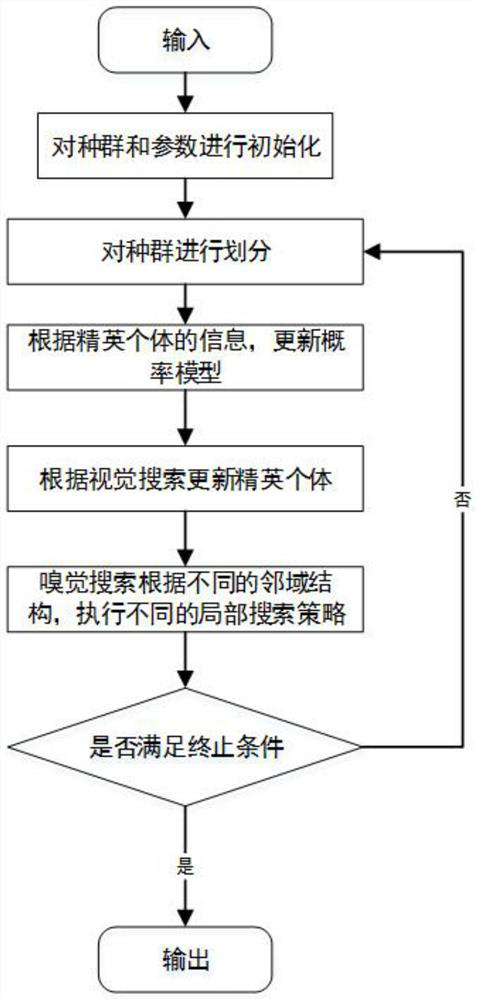

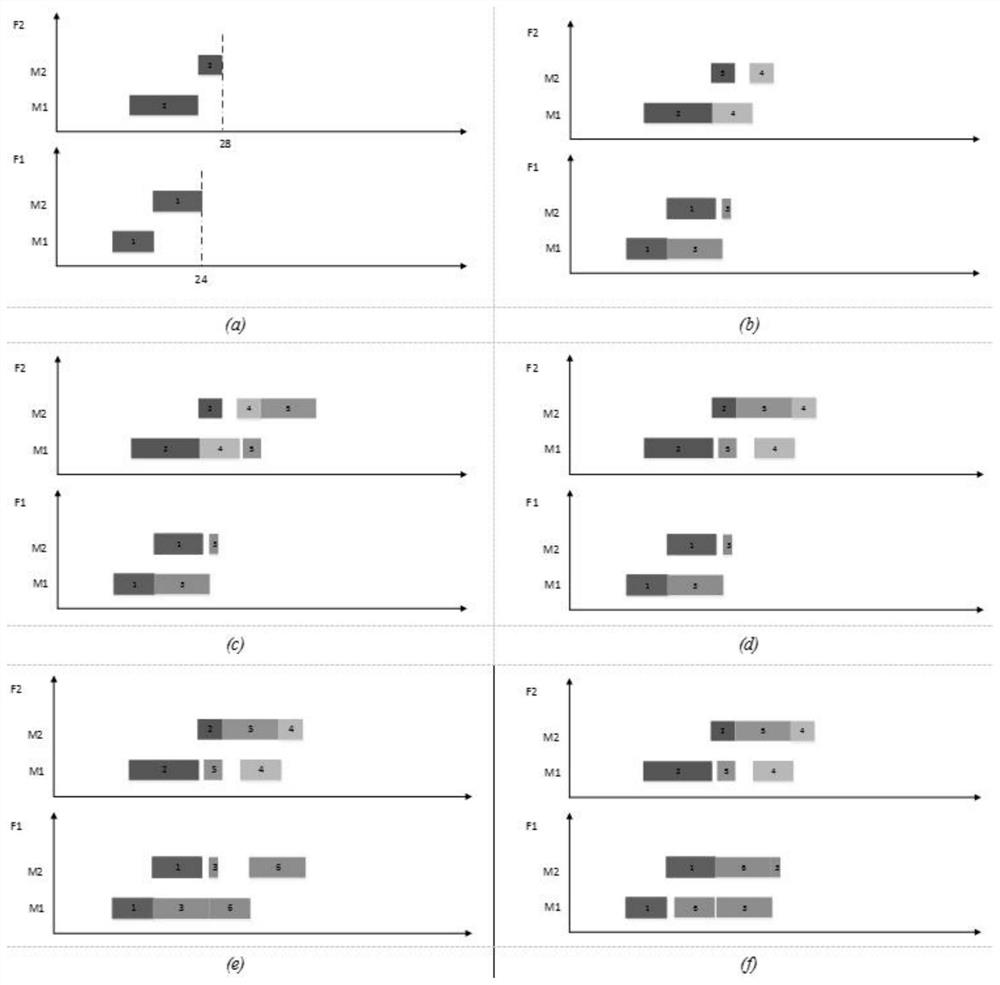

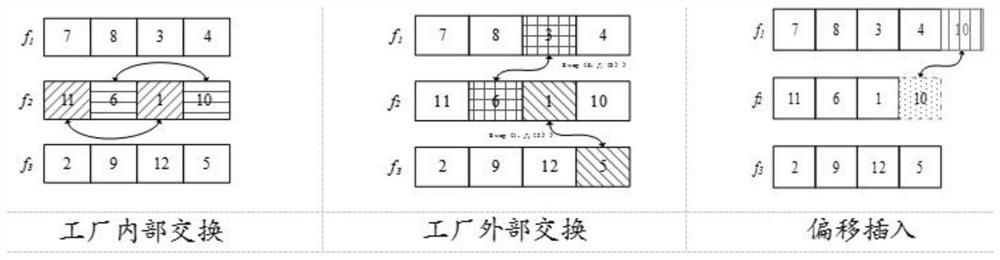

[0033] The purpose of the embodiments of the present invention is to design a simple and efficient optimized integrated system for the scheduling problem of a distributed zero-wait flow shop with a delivery window. Therefore, the fruit fly algorithm was chosen as the main optimization algorithm framework. Aiming at this problem, a discrete knowledge-driven learning fruit fly algorithm (DKLFOA) is proposed. Drosophila individuals are used to represent the discrete processing sequence in the factory. The initial population center is constructed through the knowledge-driven initialization method, and then By introducing the EDA algorithm in the visual search, through experience accumulation and feedback, the priority order of individual insertion is obtained, and then a selective local search strategy of variable neighborhood descent is introduced in the olfactory search stage. The Taillard problem test set is selected to verify the effectiveness of the proposed algorithm. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com