Method for estimating tool face angle of rotary steering drilling tool system

A technology of rotary steerable drilling and tool face angle, which is applied in directional drilling, earthwork drilling, wellbore/well components, etc., can solve the problem of low estimation accuracy of tool face angle, reduce computational complexity, improve efficiency, improve Effect of Estimation Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

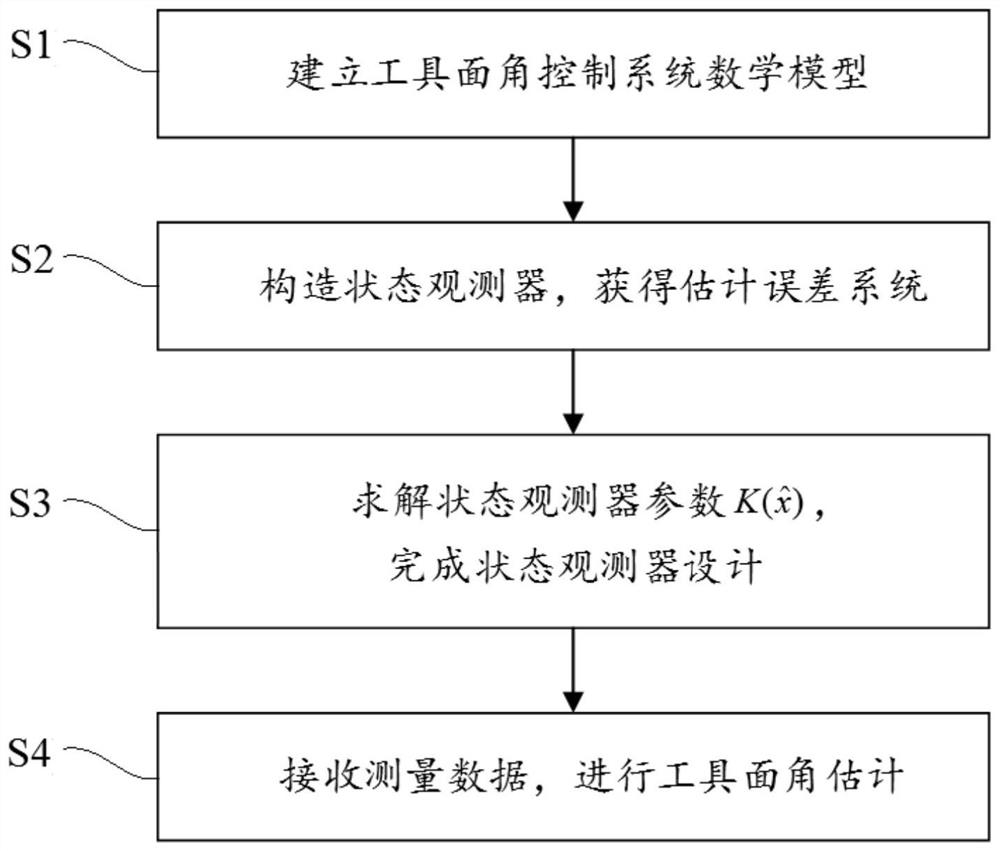

[0040] see figure 1 , an embodiment of the present invention provides a method for estimating a tool face angle of a rotary steerable drilling tool system, the specific steps of which are:

[0041] S1. Establish a mathematical model of the tool face angle control system; the specific steps are:

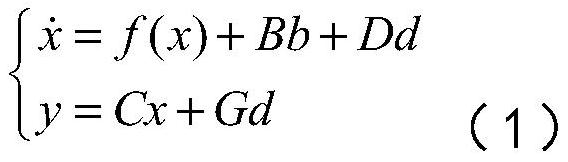

[0042]Combined with the mathematical model of the d-q coordinate system of the permanent magnet synchronous motor, the mathematical model of the tool face angle control system is constructed as follows:

[0043]

[0044] In the formula,

[0045]

[0046]

[0047] x is the state variable, y is the measurement output, is the first derivative of the state variable x, x 1 = i d ,x 2 = i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com