Chip metal wire, manufacturing method thereof and wafer

A manufacturing method and metal wire technology, which are applied in semiconductor/solid-state device components, semiconductor/solid-state device testing/measurement, semiconductor devices, etc., can solve problems such as saw blade cutting skew, chip function failure, and affecting cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

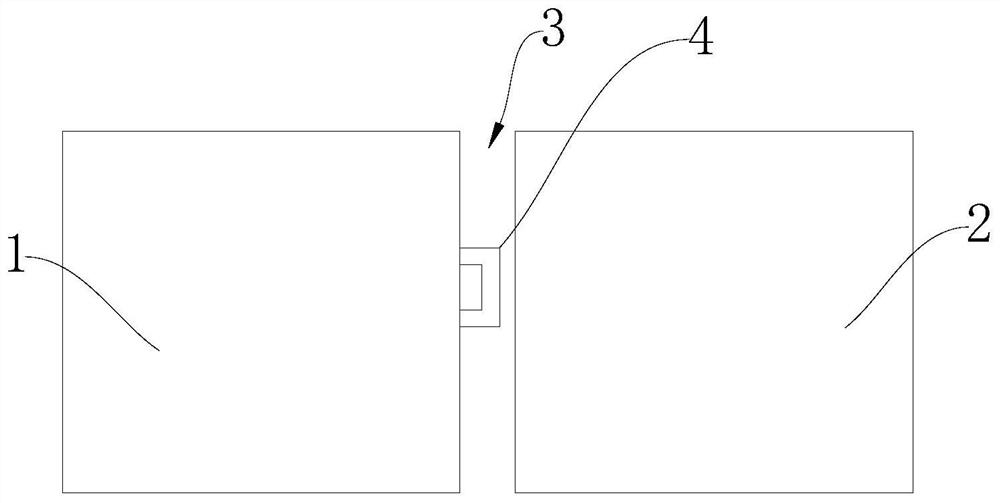

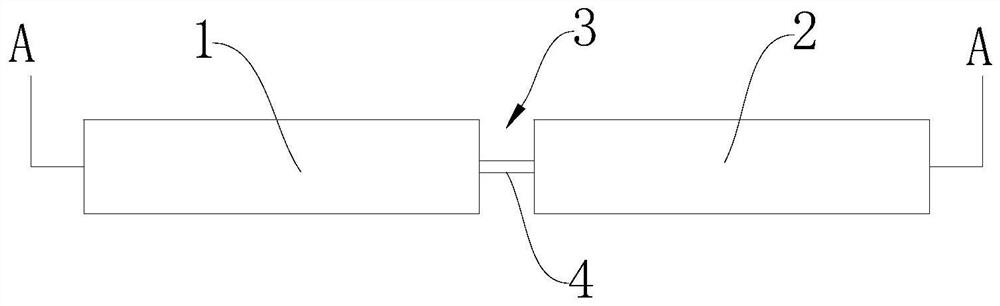

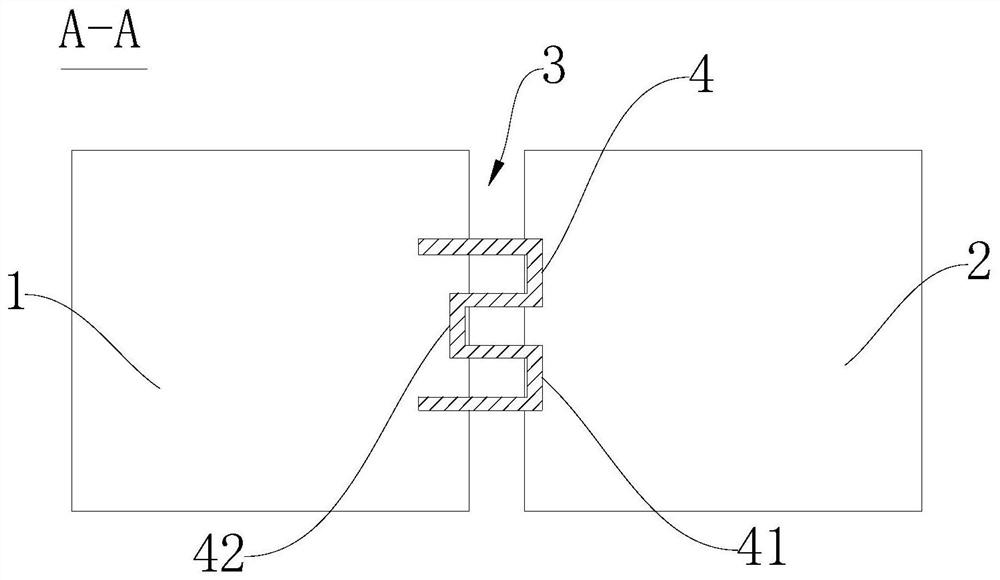

[0043] Such as figure 2 with image 3 Shown is a schematic diagram of the metal wire structure provided by the first embodiment of the present invention, such as image 3 As shown, the metal wire 4 includes a first metal wire, the first metal wire vertically crosses the scribe groove 3 between the first chip 1 and the second chip 2, and the two connecting ends of the first metal wire They are all located in the first chip 1, and the connection terminals are used to connect the test circuit modules in the chip.

[0044] In this embodiment, the first metal wire is a bow-shaped metal wire, the first metal wire has a rectangular wavy structure with one trough 42 and two crests 41, and the trough 42 of the first metal wire is located at the second In one chip 1 , two peaks 41 are located in the second chip 2 .

[0045] In this embodiment, the metal wires are copper wires.

[0046] In this embodiment, the metal wire 4 is arranged between the first chip 1 and the second chip 2 i...

Embodiment 2

[0057] Such as Figure 5 with Image 6 Shown is a schematic structural diagram of the metal wire 4 provided by the second embodiment of the present invention, as Image 6 As shown, the metal wire 4 includes a first metal wire, the first metal wire vertically crosses the scribe groove 3 between the first chip 1 and the second chip 2, and the two connecting ends of the first metal wire They are all located in the first chip 1, and the connection terminals are used to connect the test circuit modules in the chip.

[0058] In this embodiment, the first metal wire is a bow-shaped metal wire, and the first metal wire has a rectangular wavy structure with one trough 42 and two crests 41, and the troughs 42 of the first metal wire are located at In the first chip 1 , two peaks 41 are located in the second chip 2 .

[0059] In this embodiment, the metal wire 4 is arranged between the first chip 1 and the second chip 2 in a vertical arc shape.

[0060] In this embodiment, the two co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com