Double-ridge horn antenna and electronic equipment

A ridge horn and antenna technology, applied in the field of double ridge horn antenna and electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

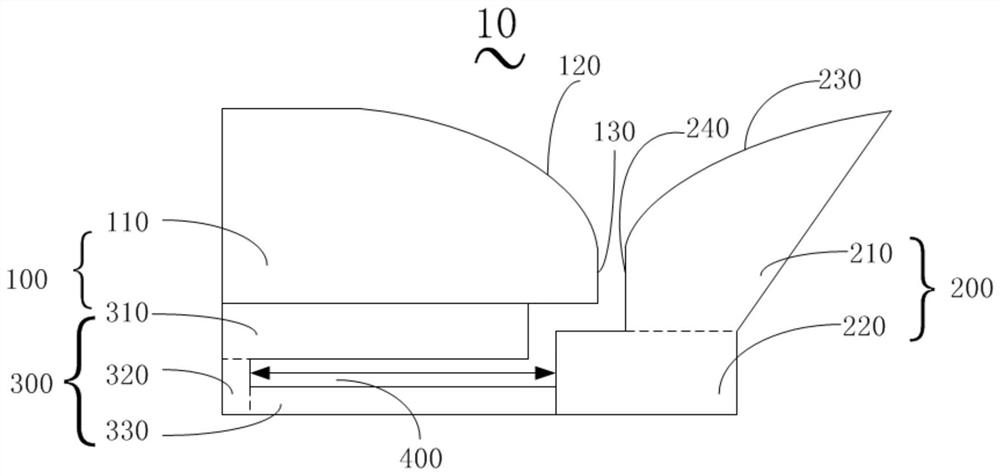

[0027] Please refer to figure 1 , figure 1 A schematic block diagram of a structure of a double-ridged horn antenna provided by an embodiment of the present invention is shown.

[0028] The double-ridged horn antenna 10 includes: a first radiation oscillator 100, a second radiation oscillator 200, and an impedance transformation balun 300; the first radiation oscillator 100 includes a first part 310 and a first radiation part 110; the second radiation The vibrator 200 includes a second radiating part 210 and a connecting part 220; the impedance transformation balun 300 includes a first part 310, a second part 320 and a third part 330 that are sequentially connected and form a "U" shape, and the first part 310 deviates from One end of the third part 330 is connected to the first radiating part 110, and one end of the third part 330 away from the second part 320 is connected to the connecting part 220, and the first radiating part 110 is connected to the second The radiating p...

Embodiment 2

[0052] An embodiment of the present invention also provides an electronic device, the electronic device includes a PCB board and the double-ridged horn antenna as described in Embodiment 1 above, and the double-ridged antenna is arranged on the PCB board.

[0053] Specifically, the antenna is mainly produced by PCB processing technology, and the installation method of the double-ridge antenna on the PCB board is plug-in, mounting, or the structure is realized by metal stamping, or it is related to the use of the antenna. The PCB board of the whole machine circuit is merged into the whole main board, which improves the portability and ease of use of the whole electronic equipment and reduces the cost.

[0054] The electronic device provided by the embodiment of the present invention has the same technical features as the double-ridged horn antenna provided by the above-mentioned embodiment 1, so it can also solve the same technical problem and achieve the same technical effect, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com