Refractory brick for ladle, preparation method of refractory brick and ladle

A technology for refractory bricks and ladles, which is applied in the manufacture of tools, casting equipment, metal processing equipment, etc., and can solve problems such as the inability to predict the residual thickness of the working layer of the ladle, ladle wear, and iron leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

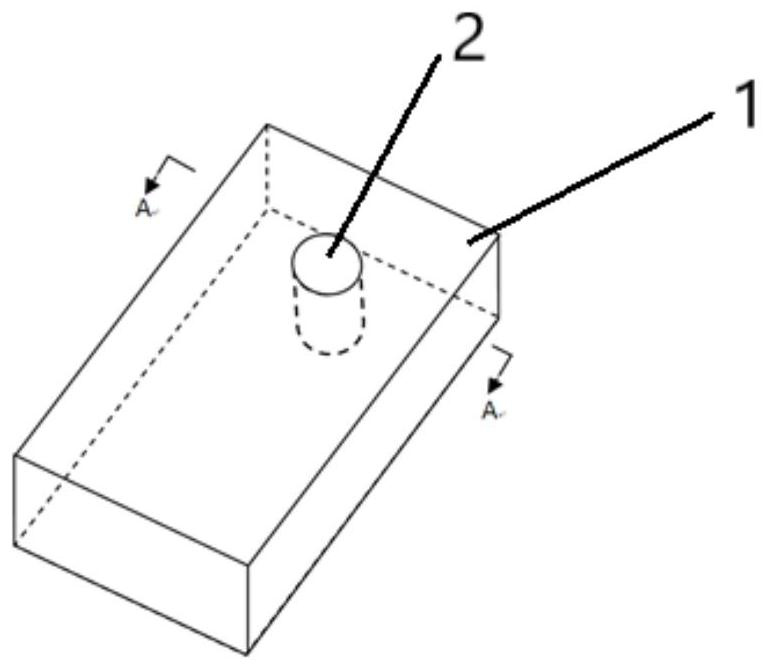

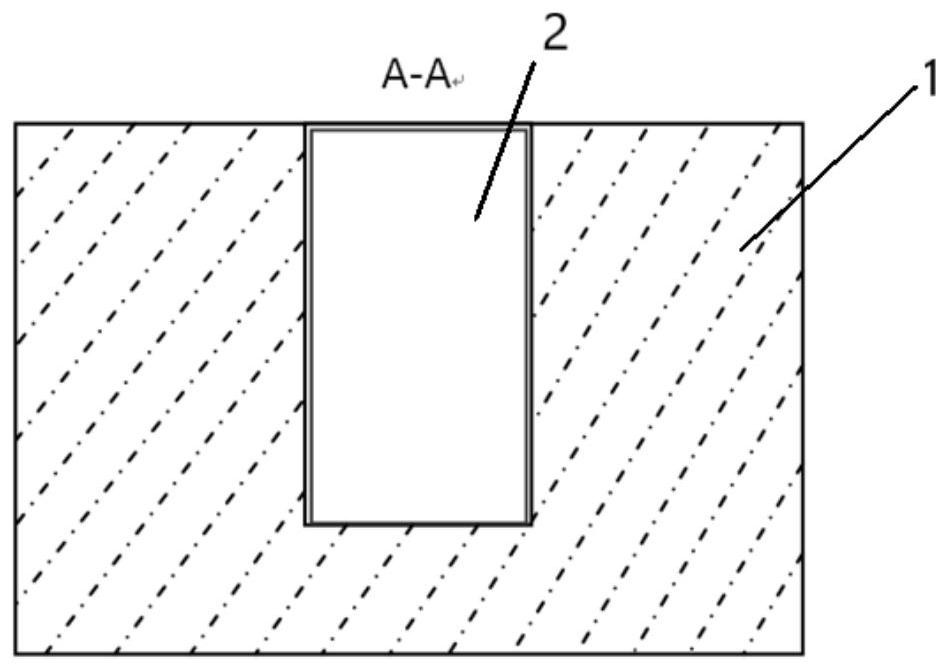

[0036] As an implementation manner of the embodiment of the present invention, the diameter of the embedded rod 2 is 15-20 mm.

[0037] The embedding rod 2 can be cylindrical, cuboid, or cube, which is not specifically limited here. When the embedded rod 2 is cylindrical, its diameter can be 15-20 mm. When the embedded rod is in other shapes, the size can be flexibly adjusted according to actual needs, and no specific limitation is made here.

[0038] As an implementation of the embodiment of the present invention, the axis of the embedded rod 2 is 90° to one surface of the molten iron brick 1, and the distance between the axis of the embedded rod 2 and the end of the molten iron brick 1 away from the molten iron is 65- 75mm. When the embedded rod 2 is cylindrical, it can be placed vertically on the axis, or horizontally, or at other angles, which is suitable for the convenience of refractory brick production and the observation of the residual thickness of the inner lining. ...

Embodiment 1

[0055] Embodiment 1 provides a wedge-shaped refractory brick for ladles. The wedge-shaped refractory brick has a length of 180 mm, two widths of 150 and 177 mm, and a height of 100 mm. The refractory bricks include aluminum silicon carbide carbon bricks and clay mullite embedded rods, wherein the upper surface of the aluminum silicon carbide carbon bricks is provided with an embedded hole, the axial direction of the embedded hole is parallel to the thickness direction of the refractory brick, the axis of the embedded hole and the length The distance between the longer broadsides is 70mm, the diameter of the embedding hole is 20mm, and the depth is 75mm. The clay mullite embedding rod is embedded into the embedding hole, the diameter of the embedding rod is 19.5mm, and the length is 74mm.

[0056] The refractory bricks provided in Example 1 are used to build the working layer of the ladle. The height direction of the refractory bricks is parallel to the vertical direction. The ...

Embodiment 2

[0058] Embodiment 2 provides a wedge-shaped refractory brick for ladle, the length of the wedge-shaped refractory brick is 220mm, the two widths are 135mm and 165mm respectively, and the height is 120mm. The refractory bricks include andalusite silicon carbide carbon bricks and carbon rods, wherein, the upper surface of the andalusite silicon carbide carbon bricks is provided with a rectangular embedded hole, the thickness direction of the rectangular parallelepiped is parallel to the thickness direction of the refractory brick, and the rectangular parallelepiped The distance between the center line of the section and the longer and wider side of the refractory brick is 70mm, the length of the cuboid is 20mm, the width is 20mm, and the depth is 75mm. The carbon rod is embedded in the embedding hole. The length of the embedding rod is 19.5mm and the width is 19.5mm and a thickness of 74mm.

[0059] The refractory bricks provided in Example 2 are used to build the working layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap