Method and system for preparing superfine copper powder

A technology of ultra-fine copper powder and ultra-fine cuprous oxide, which is applied in the field of preparing ultra-fine copper powder, and can solve the problems of low purity of ultra-fine copper powder and loss of ultra-fine copper oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

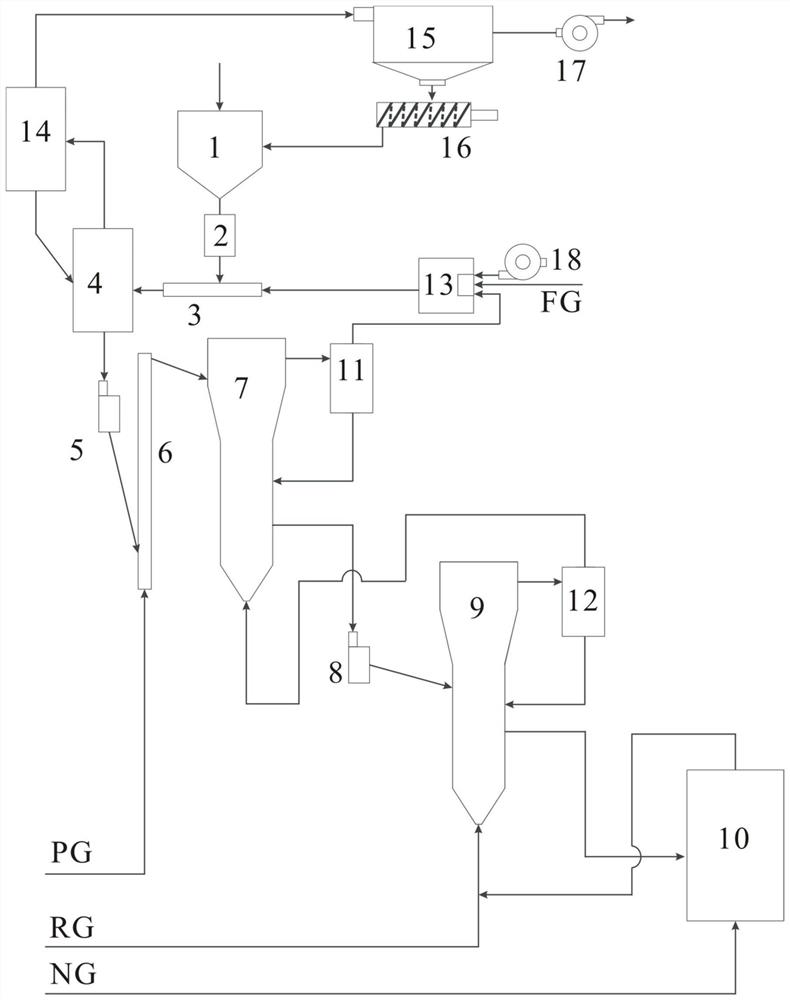

Method used

Image

Examples

Embodiment 1

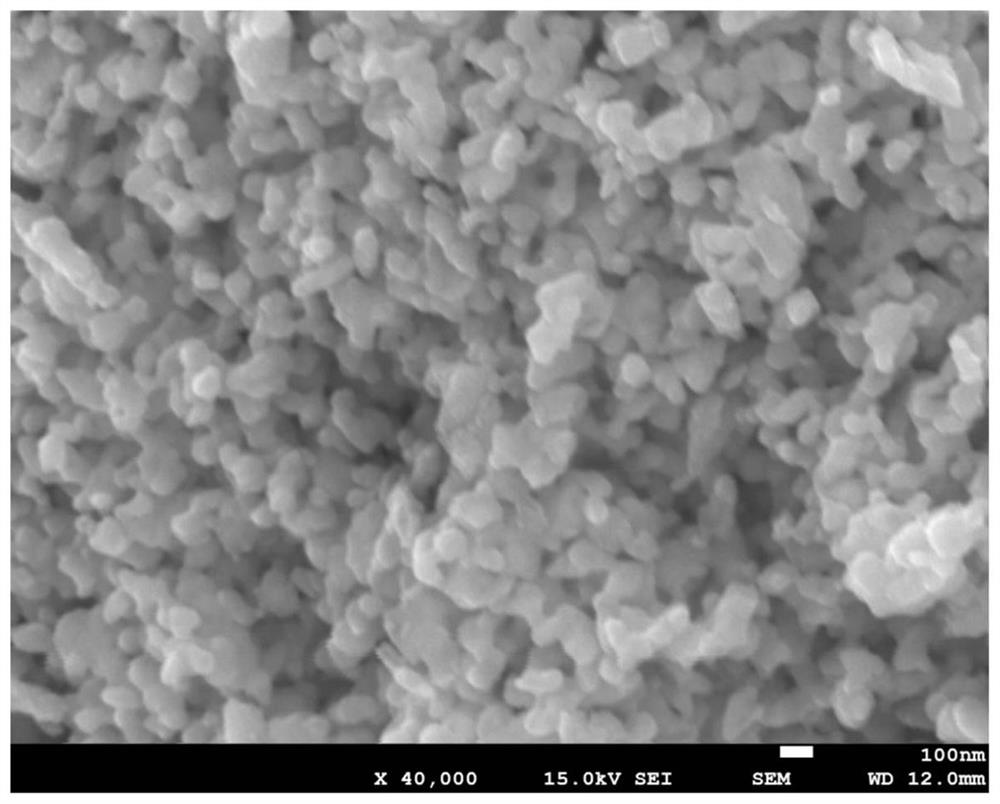

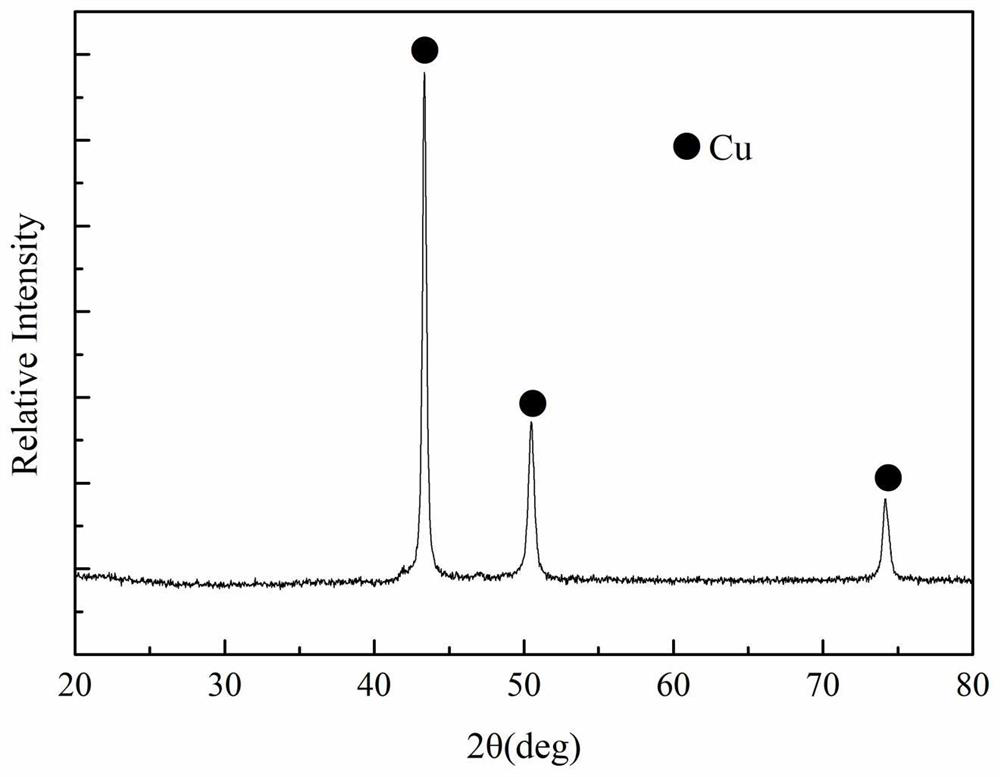

[0052] Use commercially available ultra-fine copper oxide powder (average particle size 2 The volume concentration is 50%, so that the material is in a state of turbulent fluidization. The residence time of the material reduction fluidized bed 7 is 10min; then it is sent to the cooling fluidized bed 9 through the discharge valve 8; the tail gas of the reduction fluidized bed 7 is discharged through the outlet of the first cyclone separator 11, and enters the combustion chamber 13 to burn to generate high temperature heat Flue gas, the high-temperature flue gas discharged from the outlet of the combustion chamber 13 enters the cyclone preheater 4 for heat exchange with the ultrafine copper oxide powder, and then the entrained fine powder is removed by the cyclone dust collector 14 and the bag filter 15 and then emptied; The reacted product is sent into the cooling fluidized bed 9 through the discharge valve 8, and the product contacts and exchanges heat with the reducing carrier...

Embodiment 2

[0055] Ultrafine copper oxide (average particle size 2 The volume concentration is 75%, so that the material is in a state of turbulent fluidization. The residence time of the material reduction fluidized bed 7 is 16min; then it is sent to the cooling fluidized bed 9 through the discharge valve 8; the tail gas of the reduction fluidized bed 7 is discharged through the outlet of the first cyclone separator 11, and enters the combustion chamber 13 for combustion to generate high-temperature heat Flue gas, the high-temperature flue gas discharged from the outlet of the combustion chamber 13 enters the cyclone preheater 4 for heat exchange with the ultrafine copper oxide powder, and then the entrained fine powder is removed by the cyclone dust collector 14 and the bag filter 15 and then emptied; The reacted product is sent into the cooling fluidized bed 9 through the discharge valve 8, and the product contacts and exchanges heat with the reducing carrier gas RG from the bottom of t...

Embodiment 3

[0058]Ultrafine copper oxide powder (average particle size <1.5um) prepared by copper nitrate through chemical precipitation-thermal decomposition method enters cyclone preheater 4 to preheat to 120 °C, it is sent into the reducing fluidized bed 7 through the feed valve 5 and the riser 6, contacts with the reducing carrier gas RG from the bottom of the reducing fluidized bed 7 and undergoes a reduction reaction, the reaction temperature is 210 °C, and the carrier gas has an apparent The gas velocity is 0.11m / s, and the volume concentration of reducing gas CO is 50%, so that the material is in a state of turbulent fluidization. The residence time of the material reduction fluidized bed 7 is 30min; then it is sent to the cooling fluidized bed 9 through the discharge valve 8; the tail gas of the reduction fluidized bed 7 is discharged through the outlet of the first cyclone separator 11, and enters the combustion chamber 13 for combustion to generate high-temperature heat Flue ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com