Dialyzer capping machine

A dialyzer and capping machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of product performance defects, low production efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

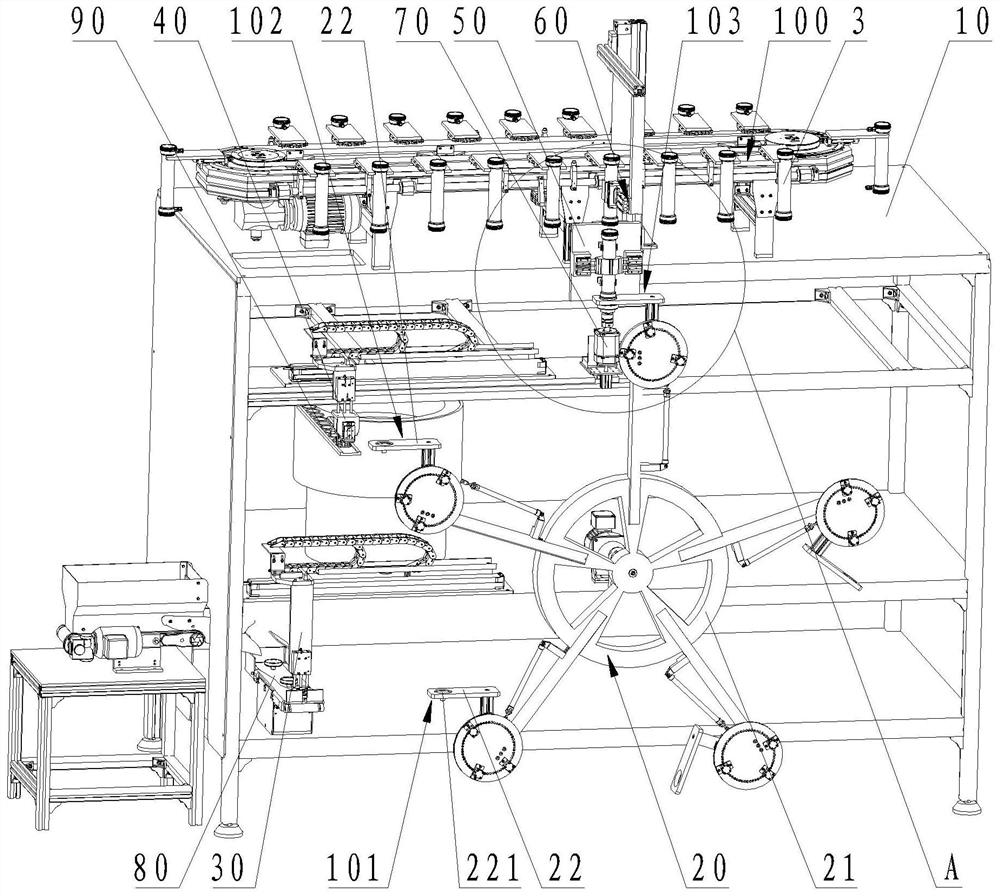

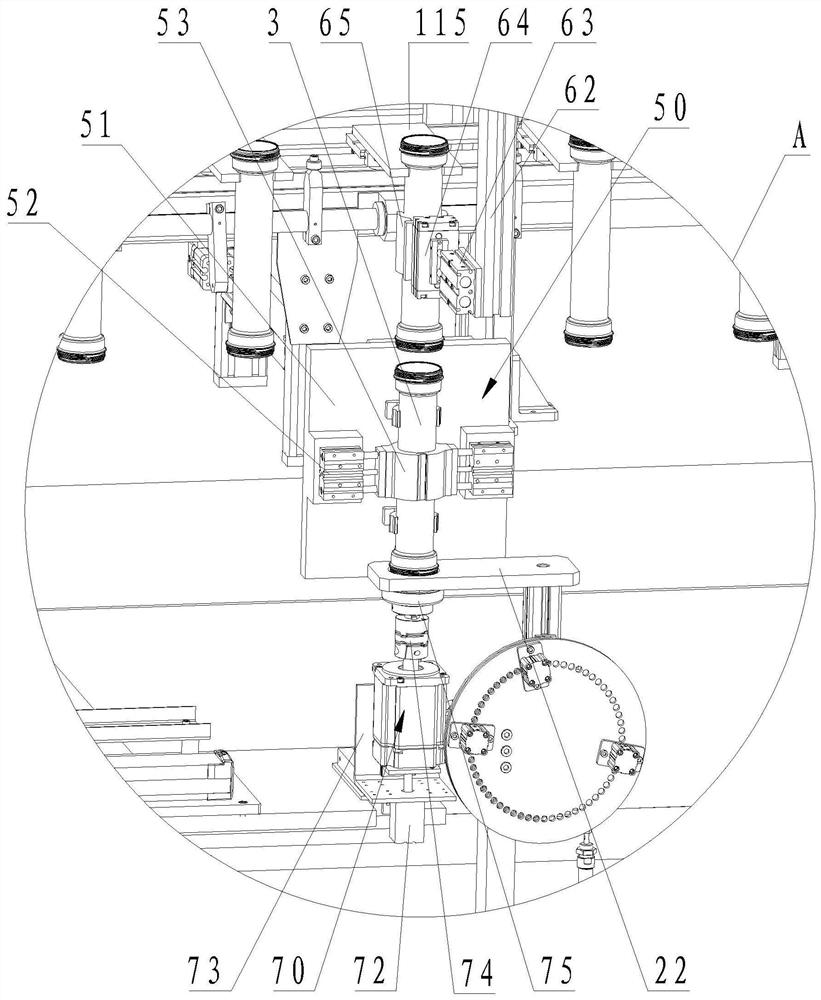

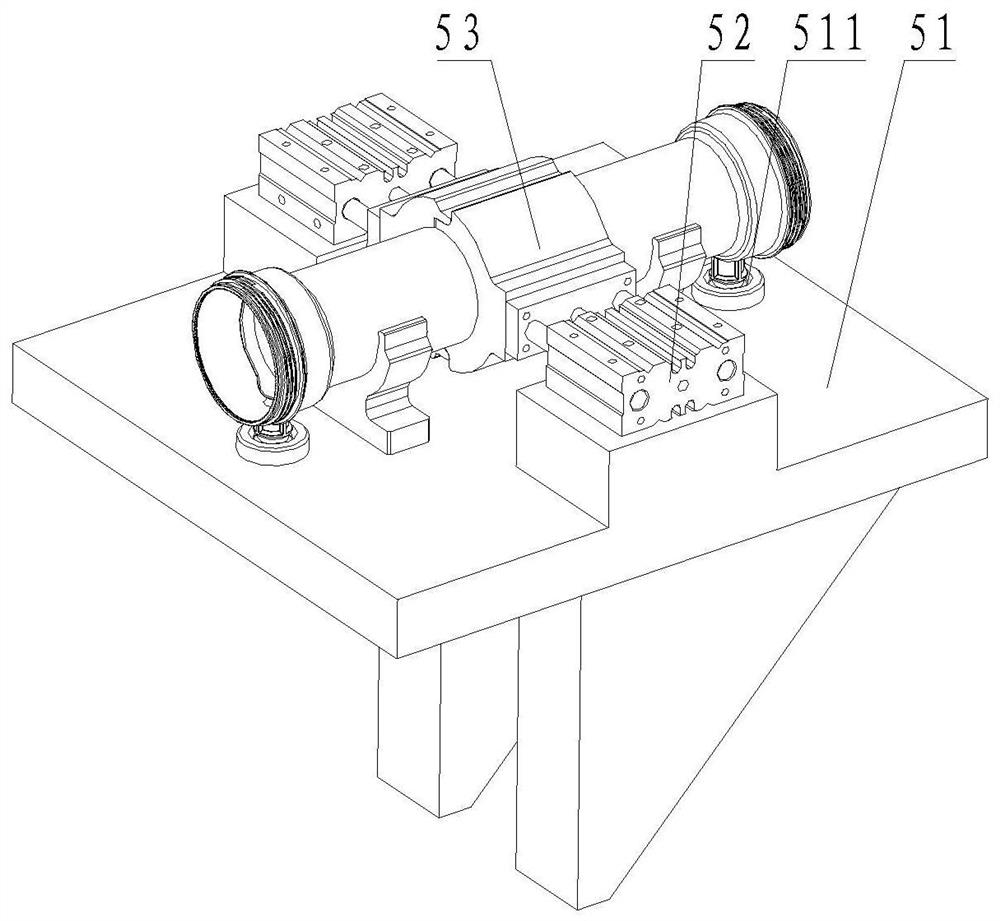

[0076] A dialyzer capping machine, such as figure 1 As shown, it includes a frame 10 , a rotating mechanism 20 , a blood cap grabbing mechanism 30 , a sealing ring grabbing mechanism 40 , a semi-finished product clamping mechanism 50 , a semi-finished product grabbing mechanism 60 and a blood cap tightening mechanism 70 . The frame 10 is provided with a blood cap upper station 101 , an upper sealing ring station 102 and a blood cap tightening station 103 sequentially from bottom to top along the height direction.

[0077] Such as figure 1 As shown, the rotating mechanism 20 includes a turntable 21 and a plurality of stages 22, the turntable 21 is arranged on the frame 10 and is rotatably arranged in the height direction of the frame 10, and a plurality of stages 22 are arranged on the turntable 21 at intervals, The stage 22 is provided with a loading hole 221 , and the upper blood cap station 101 , the upper sealing ring station 102 and the blood cap tightening station 103 ar...

Embodiment 2

[0091] On the basis of the first embodiment above, as figure 1 As shown, the dialyzer capping machine also includes a blood cap delivery mechanism 80 , a sealing ring delivery mechanism 90 and a semi-finished product delivery mechanism 100 . The blood cap conveying mechanism 80 is arranged on the frame 10 and the output end of the blood cap conveying mechanism 80 is located below the blood cap grasping mechanism 30 , and the blood cap conveying mechanism 80 is used for conveying the blood cap.

[0092] The sealing ring conveying mechanism 90 is arranged on the frame 10 and the output end of the sealing ring conveying mechanism 90 is located below the sealing ring grasping mechanism 40 , and the sealing ring conveying mechanism 90 is used for conveying the sealing ring.

[0093] The semi-finished product conveying mechanism 100 is arranged on the frame 10 and located above the semi-finished product clamping mechanism 50, and the semi-finished product conveying mechanism 100 is ...

Embodiment 3

[0115] On the basis of the above-mentioned embodiment one or embodiment two, as Figure 17 and Figure 18 As shown, the rotating mechanism 20 also includes a plurality of angle adjustment components, and the stage 22 is connected with the turntable 21 through the angle adjustment components. The angle adjustment assembly includes a first connecting piece 23, a second connecting piece 24 and a fifth telescopic cylinder 25. One end of the first connecting piece 23 is connected to the turntable 21, and the other end of the first connecting piece 23 is connected to one end of the second connecting piece 24. Hinged, the object table 22 is arranged on the other end of the second connector 24, the telescopic end of the fifth telescopic cylinder 25 is hinged with the second connector 24, and the other end of the fifth telescopic cylinder 25 is hinged with the first connector 23; When the telescopic cylinder 25 stretches, the angle between the first connector 23 and the second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com