Variable-feed turning chip breaking method capable of achieving real-time monitoring

A real-time monitoring and chip breaking technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., to solve the problems of unguaranteed chip breaking success rate and reduced tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

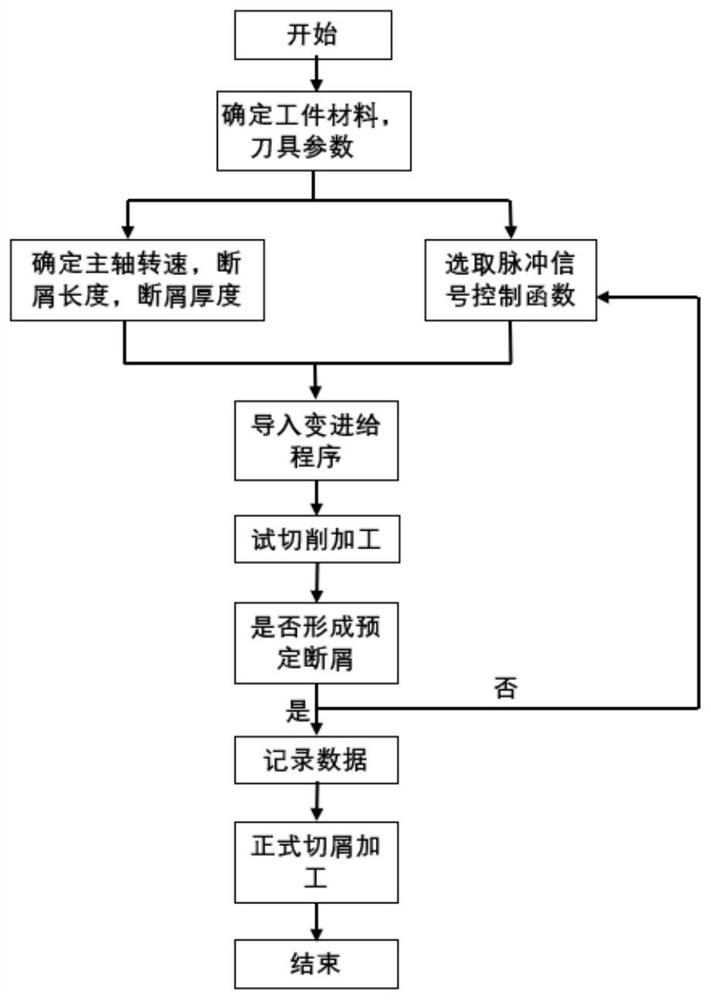

[0016] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

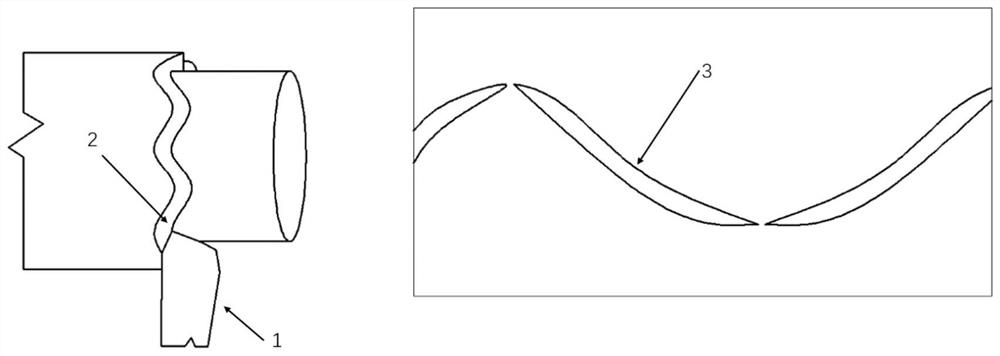

[0017] The present invention can be applied to the turning processing method, aiming at the processing material which is difficult to break chips and is easy to generate with a long chip breaking length, it refers to changing the feed rate of the cutting tool to achieve the predetermined target starting from the chip breaking size. figure 1 The specific implementation process of the present invention is shown.

[0018] Step 1: Determine the material of the workpiece to be processed, and select the appropriate tool parameters according to the material.

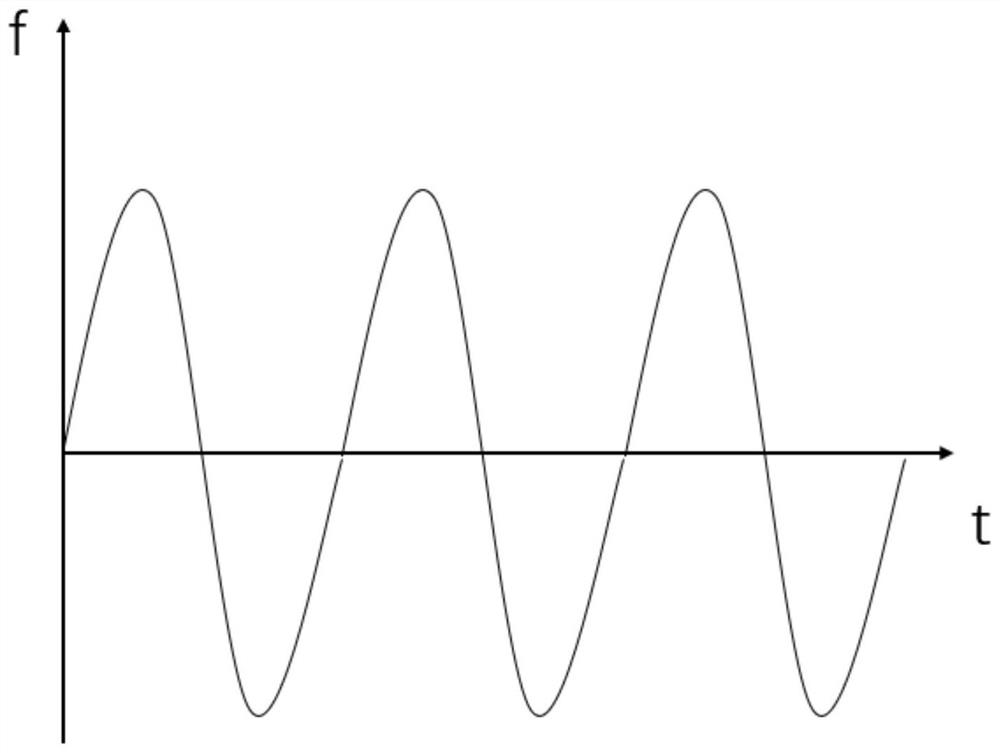

[0019] Step 2: Determine the spindle speed, set the chip breaking length L and chip breaking thickness W, and select the initial pulse signal control function. Among them, the frequency of the pulse signal has a sinusoidal relationship with the time.

[0020] Step 3: According to the above conditions, write the CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com