Passive residual heat removal system based on coupling heat pipe technology

A passive waste heat and heat pipe technology, applied in nuclear power generation, greenhouse gas reduction, climate sustainability, etc., can solve the problems of maintaining the operating temperature of thermoelectric generators, limited thermoelectric conversion efficiency of thermoelectric power generation, and inability to use heat directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

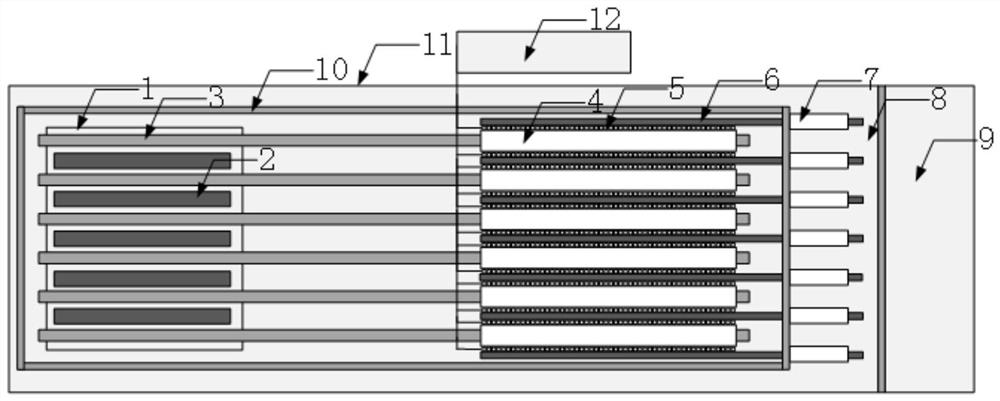

[0021] Such as figure 1 As shown, a passive waste heat removal system coupled with heat pipe technology in the present invention consists of a base 1, a fuel rod 2, a first-stage heat pipe 3, a base 4, a TEG thermoelectric power generation device 5, a second-stage heat pipe 6, and fins 7 , the seawater 8 between the inner and outer shells, the seawater 9 outside the submersible, the inner shell 10 and the outer shell 11; wherein the base 1, the fuel rod 2, the first stage heat pipe 3, the base body 4, the TEG thermoelectric power generation device 5, The heat absorption area of the second-stage heat pipe 6 is located in the inner shell 10, and the heat release area and the fins 7 of the second-stage heat pipe 6 are located between the inner shell 10 and the outer shell 11;

[0022] The pedestal 1 is located in the core and plays a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com