Semiconductor device and preparation method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

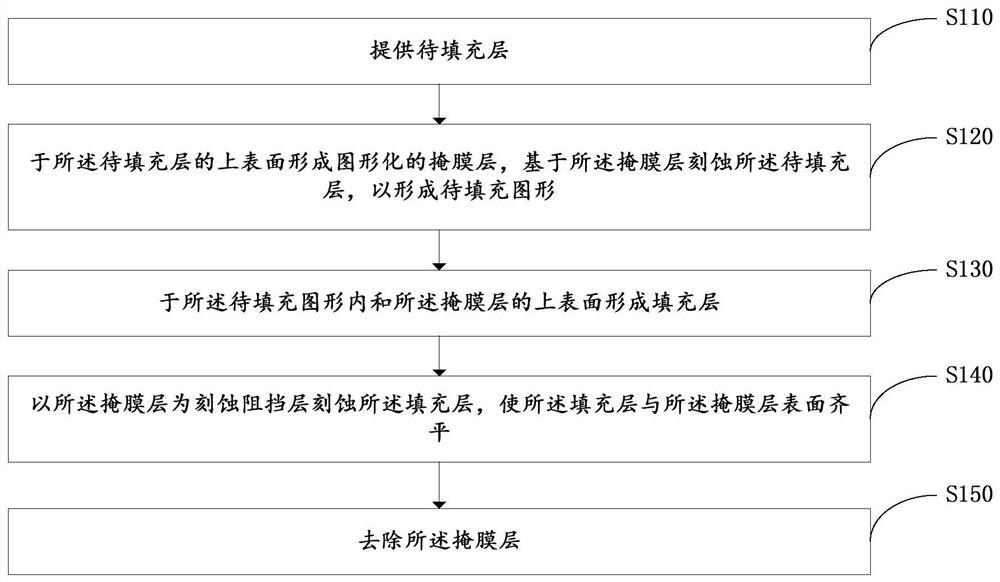

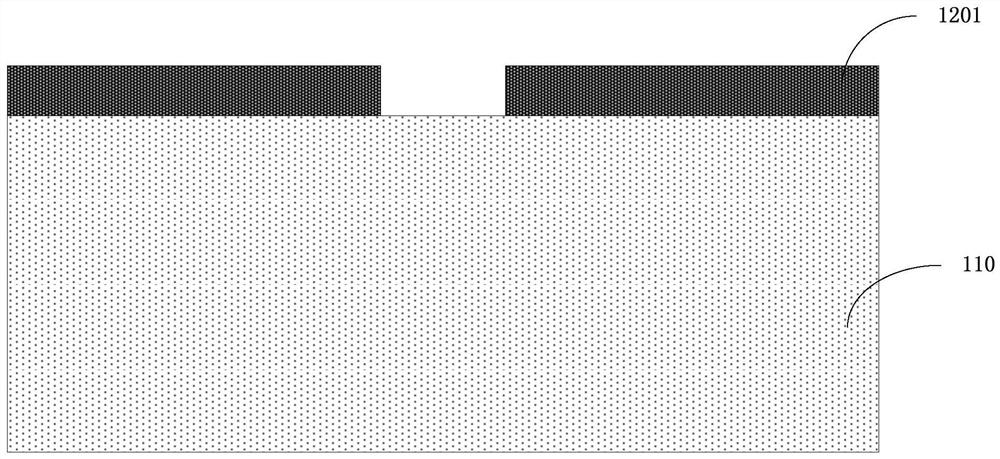

[0027] Such as figure 1 As shown, a method for preparing a semiconductor device is provided, including: providing a layer to be filled 110; forming a patterned mask layer on the upper surface of the layer to be filled 110, and etching the layer to be filled 110 based on the mask layer to form a layer to be filled. Filling the pattern; forming a filling layer 140 in the pattern to be filled and on the upper surface of the mask layer; using the mask layer as an etching barrier layer to etch the filling layer 140 so that the filling layer 140 is flush with the surface of the mask layer; removing the mask layer.

[0028] S110: providing the layer 110 to be filled, such as figure 2 shown.

[0029] In one embodiment, the layer to be filled 110 includes a dielectric layer.

[0030] In one embodiment, the dielectric layer includes silicon dioxide or a low dielectric constant material.

[0031] In one embodiment, step S110 includes:

[0032] S1101: providing a substrate;

[0033...

Embodiment 2

[0078] Such as Figure 8 As shown, a semiconductor device is provided, including: a layer to be filled 110, the layer to be filled 110 has a pattern to be filled; a patterned mask layer, located on the upper surface of the layer to be filled, the patterned mask layer exposes the layer to be filled Pattern; filling layer 140, located in the pattern to be filled, and the filling layer 140 is flush with the surface of the mask layer.

[0079] In one embodiment, the pattern to be filled includes a first pattern to be filled 1301 and a second pattern to be filled 1302 interconnected, the first pattern to be filled 1301 includes a through hole, and the second pattern to be filled 1302 includes a trench.

[0080] In one embodiment, the layer to be filled 140 includes a dielectric layer, the filling layer 140 includes a metal layer, and the metal layer includes ruthenium or cobalt.

[0081] In one embodiment, the dielectric layer includes silicon dioxide or a low dielectric constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com