Sulfated vanadium-chromium-titanium denitration catalyst as well as preparation method and application thereof

A sulfation and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

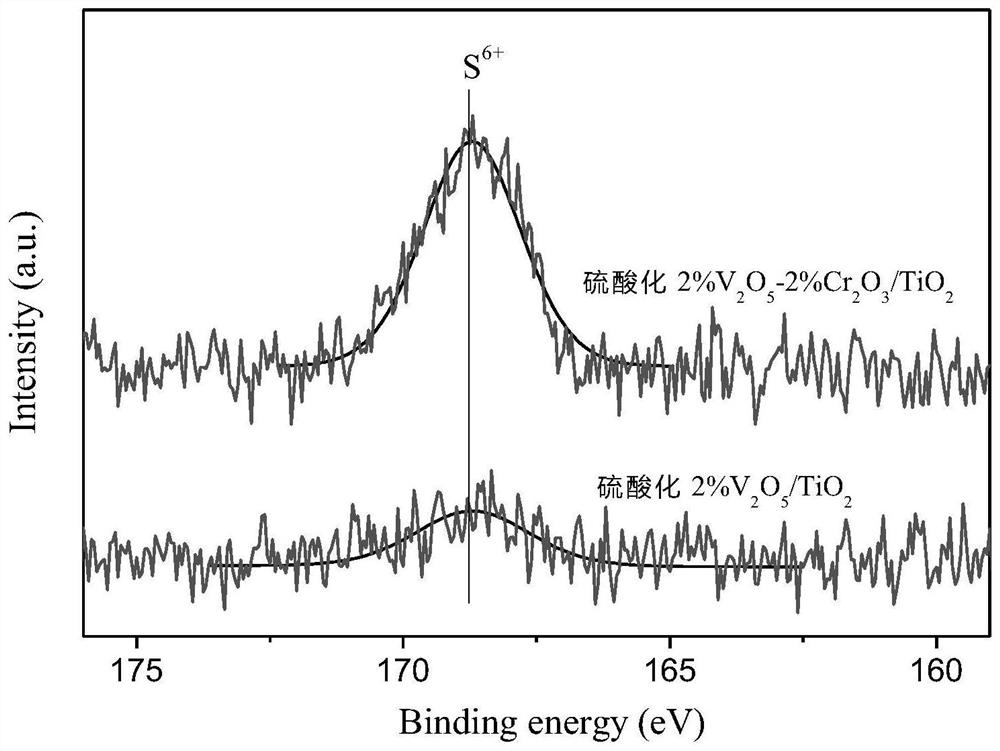

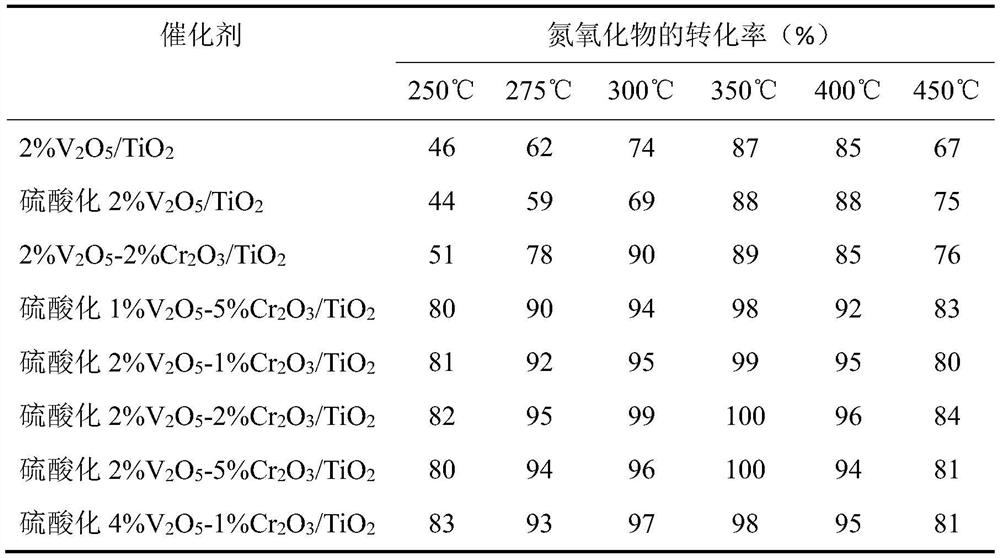

[0025] Example 1: Sulfated 1% V 2 o 5 -5%Cr 2 o3 / TiO 2 Catalyst preparation

[0026] a) Take 2.1ml of 0.10mol / L ammonium metavanadate solution and 3.3ml of 0.40mol / L chromium nitrate solution, add deionized water, stir in a water bath at 30°C to obtain a mixed solution; add 1.88g of titanium dioxide to the mixed solution, stirred for 2 hours to obtain a slurry;

[0027] b) Dry the slurry prepared in step a) at 120°C for 12 hours to obtain a dry sample; place the sample in a muffle furnace and bake at 600°C for 4 hours to obtain 1% V 2 o 5 -5%Cr 2 o 3 / TiO 2 catalyst;

[0028] c) Pass the catalyst prepared in step b) into 500ppm SO 2 , 5%O 2 , using nitrogen as the balance gas, the flow rate is 300ml / min, sulfurated at 400°C for 1 hour, and the sulfated 1% V 2 o 5 -5%Cr 2 o 3 / TiO 2 catalyst.

Embodiment 2

[0029] Example 2: Sulfated 2% V 2 o 5 -1%Cr 2 o 3 / TiO 2 Catalyst preparation

[0030] a) Take 2.1ml of 0.20mol / L ammonium metavanadate solution and 1.3ml of 0.20mol / L chromium nitrate solution, add deionized water, stir in a water bath at 60°C to obtain a mixed solution; add 1.94g of titanium dioxide to the mixed solution solution, stirred for 6 hours to obtain a slurry;

[0031] b) Dry the slurry prepared in step a) at 100°C for 24 hours to obtain a dry sample; place the sample in a muffle furnace and bake at 400°C for 8 hours to obtain 2% V 2 o 5 -1%Cr 2 o 3 / TiO 2 catalyst;

[0032] c) Pass the catalyst prepared in step b) into 100ppm SO 2 , 10%O 2 , using nitrogen as the balance gas, the flow rate is 500ml / min, sulfurated at 200 ° C for 12 hours, to obtain the sulfated 2% V 2 o 5 -1%Cr 2 o 3 / TiO 2 catalyst.

Embodiment 3

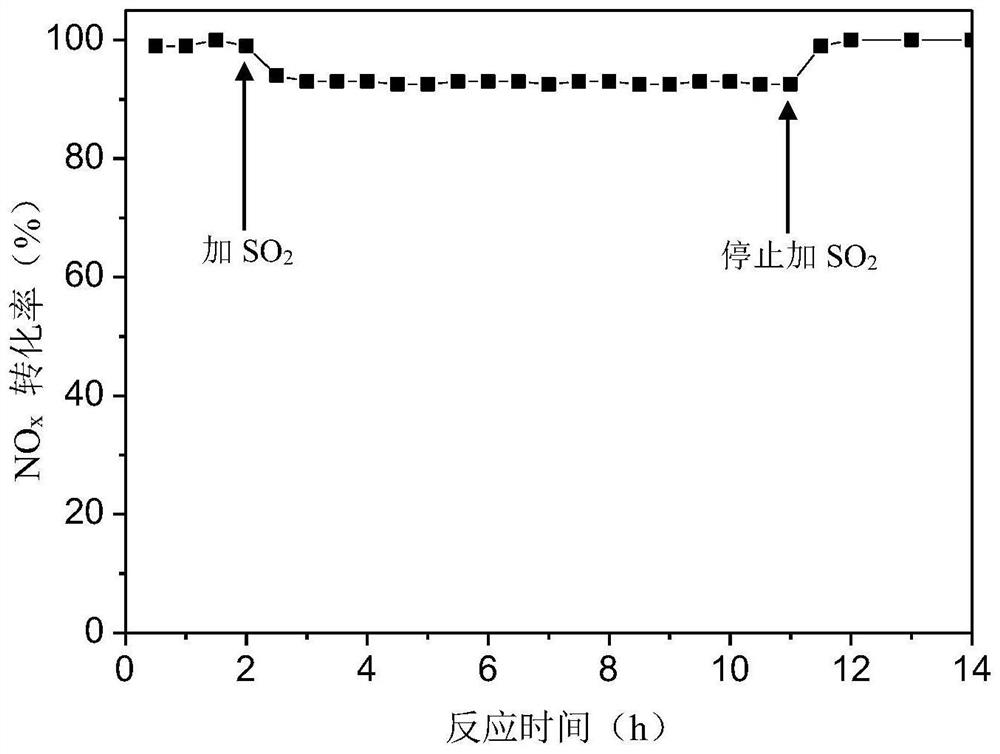

[0033] Example 3: Sulfated 2% V 2 o 5 -2%Cr 2 o 3 / TiO 2 Catalyst preparation

[0034] a) Take 2.1ml of 0.20mol / L ammonium metavanadate solution and 2.6ml of 0.20mol / L chromium nitrate solution, add deionized water, stir in a water bath at 40°C to obtain a mixed solution; add 1.92g of titanium dioxide to the mixed solution solution, stirred for 4 hours to obtain a slurry;

[0035] b) Dry the slurry prepared in step a) at 120°C for 12 hours to obtain a dry sample; place the sample in a muffle furnace and bake at 500°C for 6 hours to obtain 2% V 2 o 5 -2%Cr 2 o 3 / TiO 2 catalyst;

[0036] c) Pass the catalyst prepared in step b) into 200ppm SO 2 , 5%O 2 , use nitrogen as balance gas, flow rate is 300ml / min, sulfation at 400°C for 3 hours, to obtain sulfated 2% V 2 o 5 -2%Cr 2 o 3 / TiO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com