A kind of chromium-tungsten-zirconium composite oxide denitrification catalyst and its preparation method and application

A composite oxide and denitrification catalyst technology, which is applied in the field of environmental catalysis and air pollution control, can solve the problems of carrier crystal transformation, narrow operating temperature window, and high catalyst cost, so as to improve acidity, improve oxidation-reduction performance, and good denitrification active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

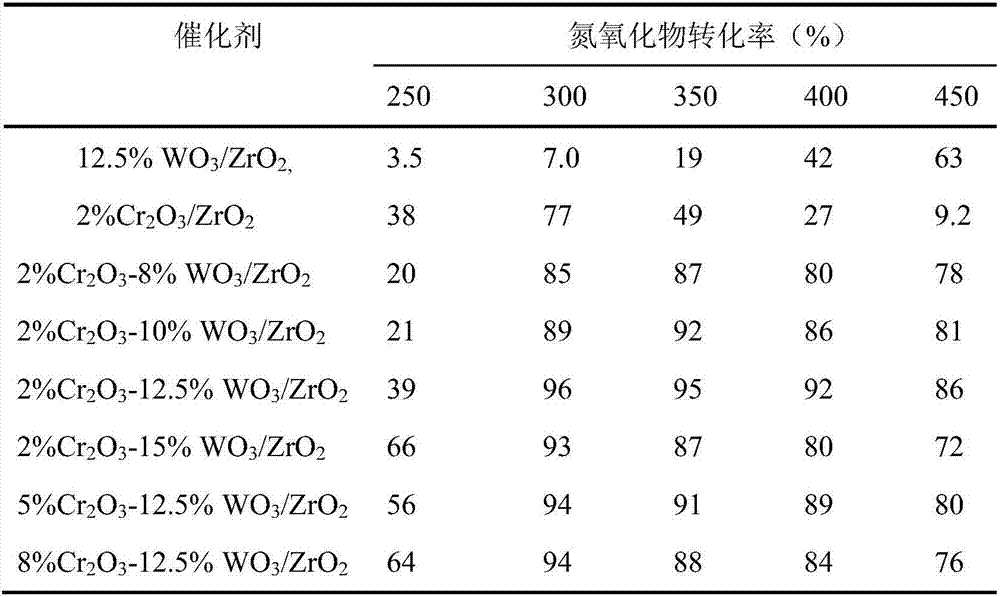

[0019] Example 1: 2% Cr 2 o 3 -8% WO 3 / ZrO 2 Preparation of composite oxide catalyst

[0020] a) Take 37.3mL of 1mol / L zirconium oxychloride solution, add deionized water, add ammonia water drop by drop under stirring at room temperature until the pH is 9, filter the obtained precipitate with suction, and then dry it at 120°C for 12 hours, a dry sample was prepared, and the resulting sample was ground into a powder.

[0021] b) Take 2.47mL of 0.1mol / L ammonium tungstate solution, add deionized water, stir evenly at room temperature, add the powder obtained in step a) into the solution, and stir for 2 hours to obtain a slurry;

[0022] c) Dry the slurry prepared in step b) at 120°C for 12 hours to prepare a dry sample, place the sample in a muffle furnace and bake at 800°C for 3 hours, and grind the sample after cooling into powder;

[0023] d) Take 1.34mL 1mol / L chromium nitrate solution, add deionized water, stir evenly at room temperature, add the powder obtained in s...

Embodiment 2

[0025] Example 2: 2% Cr 2 o 3 -10% WO 3 / ZrO 2 Preparation of composite oxide catalyst

[0026] a) Take 36.5mL of 1mol / L zirconium oxychloride solution, add deionized water, add ammonia water drop by drop under stirring at room temperature until the pH is 10, filter the obtained precipitate, and then dry it at 120°C for 24 hours, a dry sample was prepared, and the resulting sample was ground into a powder.

[0027] b) Take 3.08mL of 0.1mol / L ammonium tungstate solution, add deionized water, stir evenly at room temperature, add the powder obtained in step a) into the solution, and stir for 4 hours to obtain a slurry;

[0028] c) Dry the slurry prepared in step b) at 120°C for 24 hours to prepare a dry sample, place the sample in a muffle furnace and bake at 800°C for 6 hours, and grind the sample after cooling into powder;

[0029] d) Take 1.34mL 1mol / L chromium nitrate solution, add deionized water, stir evenly at room temperature, add the powder obtained in step c) into...

Embodiment 3

[0031] Example 3: 2% Cr 2 o 3 -12.5% WO 3 / ZrO 2 Preparation of composite oxide catalyst

[0032] a) Take 35.5mL of 1mol / L zirconium oxychloride solution, add deionized water, add ammonia water drop by drop under stirring at room temperature until the pH is 9, filter the obtained precipitate with suction, and then dry it at 120°C for 24 hours, a dry sample was prepared, and the resulting sample was ground into a powder.

[0033] b) Take 1.92mL of 0.2mol / L ammonium tungstate solution, add deionized water, stir evenly at room temperature, add the powder obtained in step a) into the solution, and stir for 4 hours to obtain a slurry;

[0034]c) Dry the slurry prepared in step b) at 120°C for 24 hours to prepare a dry sample, place the sample in a muffle furnace and bake at 800°C for 4 hours, and grind the sample after cooling into powder;

[0035] d) Take 1.34mL 1mol / L chromium nitrate solution, add deionized water, stir evenly at room temperature, add the powder obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com