Nuclear power station shaft seal main pump shaft seal stationary ring machining process and nuclear power station shaft seal main pump shaft seal stationary ring machining process equipment

A processing technology, a technology for nuclear power plants, applied in metal processing equipment, nuclear power generation, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

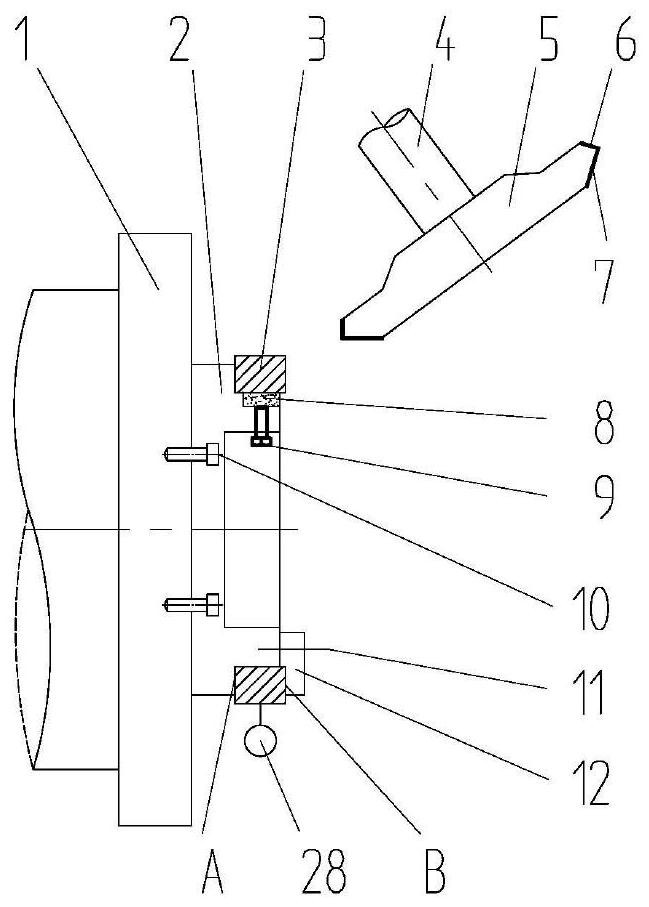

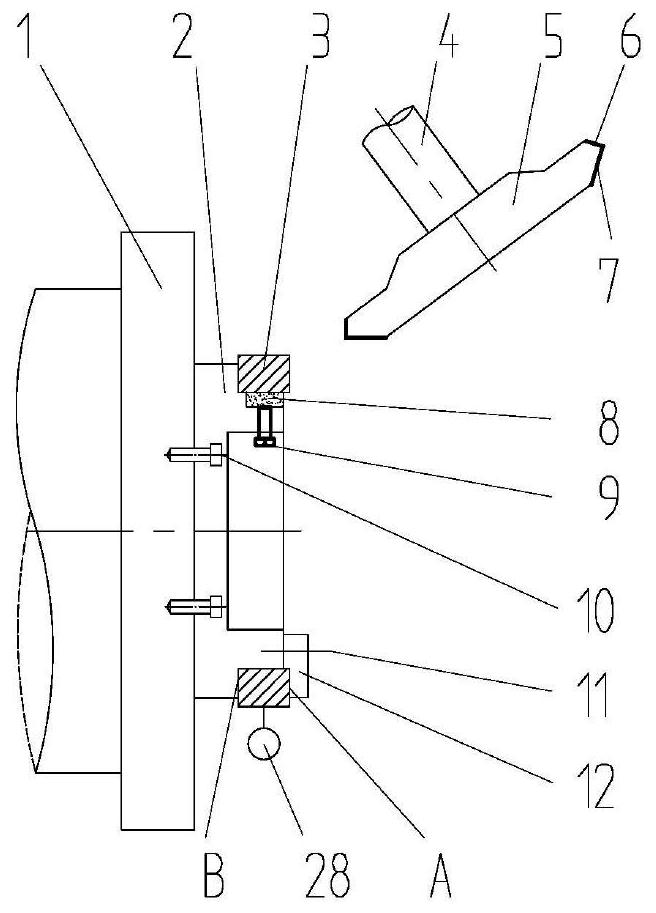

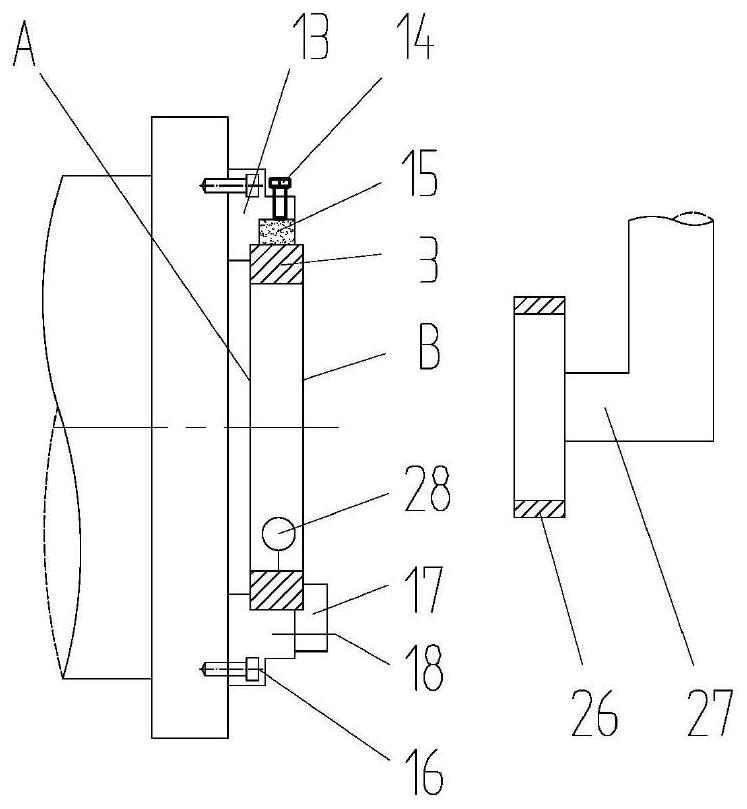

[0039] Such as figure 1 As shown, a nuclear power plant shaft seal main pump shaft seal static ring processing technology, the ground tire 2 of the outer circle of the static ring is magnetically adsorbed on the electromagnetic disk 1, and the first bolt 10 is used to grind the outer circle of the static ring. Tire 2 is fixed on the electromagnet disk 1, and static ring 3 is installed on the ground tire 2 of the outer circle of the static ring, and the first block 8 is tightened with the second bolt 9, and the inner hole of the static ring 3 is tightened with the first bolt 9. The pressure plate 12 compresses the static ring 3 by tightening the third bolt 11, monitors the outer circle of the static ring 3 with the dial indicator 28, starts the rotating electromagnet disk 1 to drive the static ring 3 to rotate, when the static ring 3 rotates to 0°, 90°, At 180° and 270°, write down the readings of the dial gauge 28 respectively, and adjust the rotation center of the static ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com