Fiber reinforced composite material with surface self-repairing function

A fiber-reinforced and composite material technology, applied in the direction of epoxy resin coatings, synthetic resin layered products, polyurea/polyurethane coatings, etc., can solve problems such as complex conditions, limited capacity of repairing agents, and failure to achieve multiple self-repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

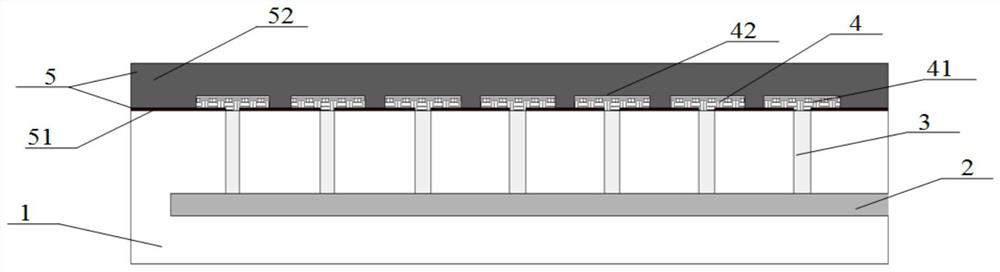

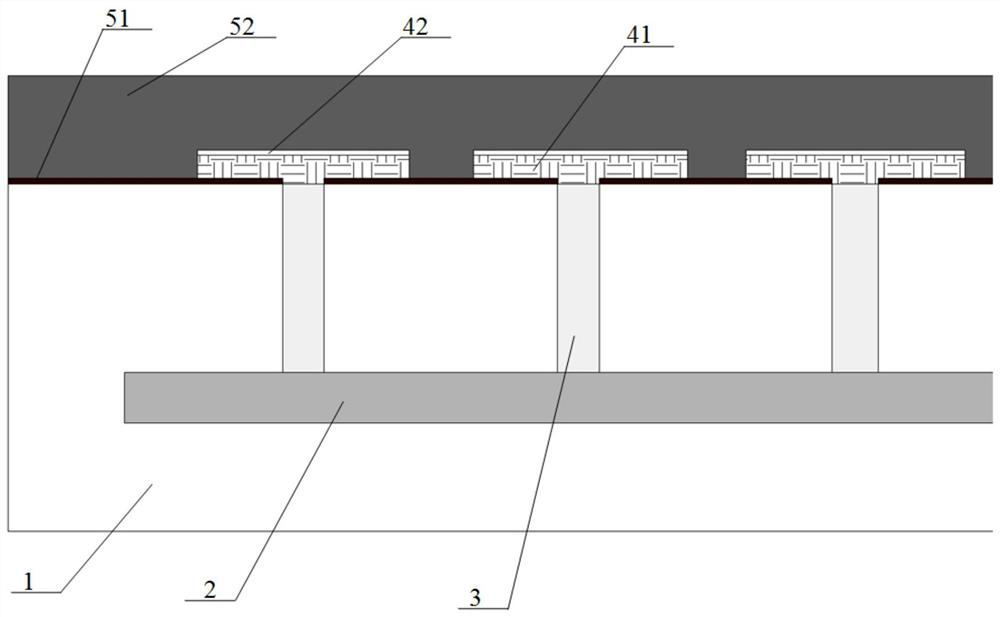

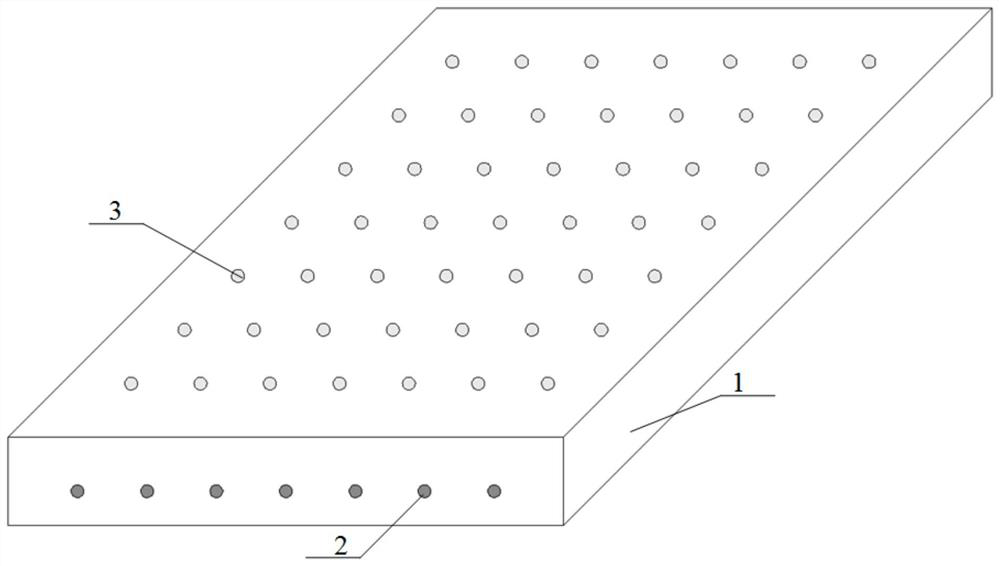

[0023] The schematic diagram of the structure of the fiber-reinforced composite material with surface self-repair function in this embodiment is as follows figure 1 and 2 As shown, the main pipeline 2 is pre-embedded in the fiber braided base 1, and the secondary pipeline 3 is opened from the surface layer to communicate with the main pipeline 2 on the fiber braided base 1, and the secondary pipeline 3 is perpendicular to the main pipeline 2; 1 The surface layer is coated with a layer of primer 51, the pipe opening of the secondary pipeline 3 is covered with a micro-nano structure film 41, and the micro-nano structure film 41 is covered with a plastic protective film 42; the plastic protective film 42 is coated with a layer of primer 52 The paint 52 ; the micro-nano structure film 41 and the plastic protective film 42 jointly constitute the flow-guiding layer 4 ; the primer 51 and the top paint 52 jointly constitute the coating 5 .

[0024] The specific preparation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com