Polymer cement waterproof coating and preparation method thereof

A technology of waterproof coatings and polymers, applied in the direction of cement coatings, coatings, etc., can solve problems such as coating film cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

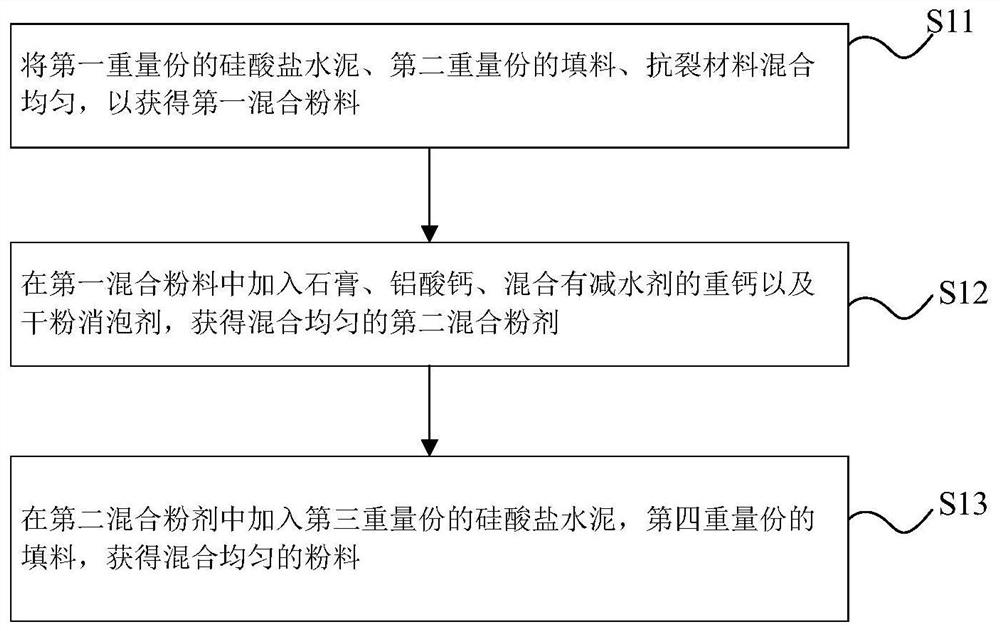

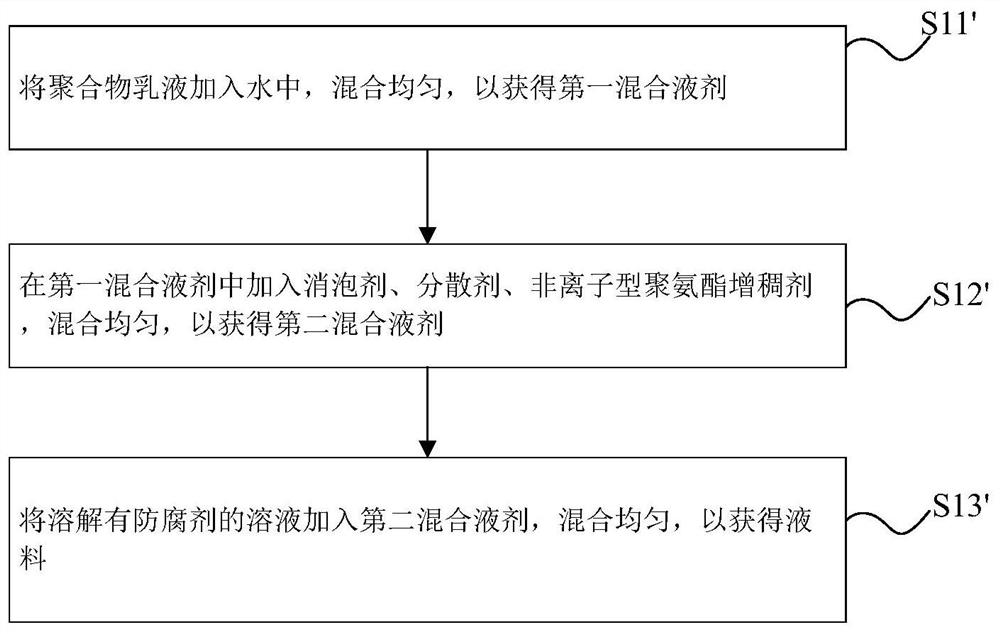

[0070] Such as figure 2 As shown, the second aspect of the embodiment of the present application provides a method for preparing a polymer cement waterproof coating, the method comprising:

[0071] S11, uniformly mixing the Portland cement of the first part by weight, the filler of the second part by weight, and the anti-cracking material to obtain the first mixed powder;

[0072] S12, adding gypsum, calcium aluminate, heavy calcium mixed with a water reducer, and a dry powder defoamer to the first mixed powder to obtain a uniformly mixed second mixed powder;

[0073] S13, adding the third part by weight of Portland cement and the fourth part by weight of filler to the second mixed powder to obtain a uniformly mixed powder,

[0074] Wherein, the ratio of the first weight part to the third weight part is 1-1.5; the ratio of the second weight part to the fourth weight part is 1-1.5.

[0075] In some embodiments, the anti-crack material is selected from at least one of hollow ...

specific Embodiment

[0082]The following examples describe the present disclosure more specifically, and these examples are for illustrative purposes only, since various modifications and changes within the scope of the present disclosure will be apparent to those skilled in the art. Unless otherwise stated, all parts, percentages, and ratios reported in the following examples are based on weight, and all reagents used in the examples are commercially available or synthesized according to conventional methods, and can be directly The instruments used without further processing, as well as in the examples, are commercially available.

[0083] 【Powder and liquid ratio of polymer cement waterproof coating】

[0084] 1. Table 1 is the powder proportioning of Embodiment 1 to Embodiment 6 and Comparative Example 1.

[0085] Table 1

[0086]

[0087]

[0088] 2, table 2 is the formula ratio of the liquid preparation of embodiment 1 to embodiment 6 and comparative example 1

[0089] Table 2

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com