Self-adhesive sheet metal protective film and preparation method thereof

A metal plate and protective film technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of protective film curling damage, etc., to reduce white pollution, improve shading rate, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

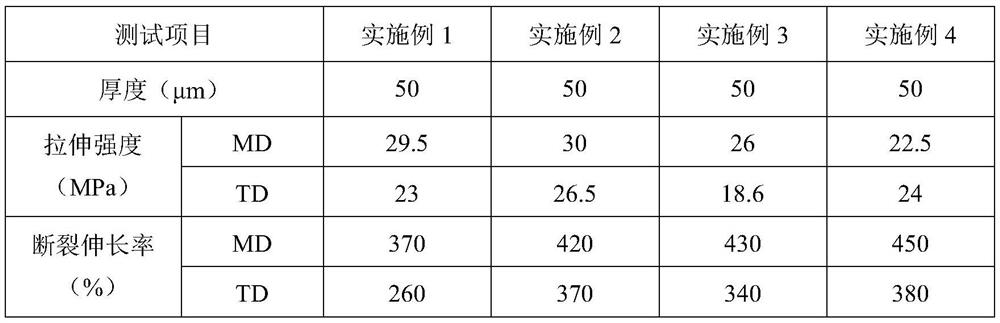

Examples

Embodiment 1

[0041] S1, material preparation:

[0042] The release layer includes by weight: 20 parts of high-pressure polyethylene, 80 parts of linear polyethylene, 3 parts of white color masterbatch, 20 parts of filler, and 6 parts of flame retardant;

[0043] The filling layer includes by weight: 20 parts of high-pressure polyethylene, 2 parts of black color masterbatch, 80 parts of calcium carbonate filler masterbatch, and 5 parts of flame retardant;

[0044] The transition layer includes by weight: 20 parts of high-pressure polyethylene, 80 parts of linear polyethylene, 3 parts of white color masterbatch, 20 parts of filler, and 6 parts of flame retardant;

[0045] The adhesive layer is ethylene-vinyl acetate copolymer, and the mass content of vinyl acetate is 18%.

[0046] Add the release layer, filling layer, transition layer, and adhesive layer into different mixers according to the mass ratio, stir and dry for 15 minutes.

[0047] S2. Shearing and heating of screw plasticizing e...

Embodiment 2

[0052] S1, material preparation:

[0053] The release layer includes by weight: 50 parts of high pressure polyethylene, 50 parts of linear polyethylene, 5 parts of white color masterbatch, 25 parts of filler, 5 parts of flame retardant,

[0054] The filling layer includes by weight: 50 parts of high pressure polyethylene, 4 parts of black color masterbatch, 100 parts of calcium carbonate filling masterbatch, 8 parts of flame retardant,

[0055] The transition layer includes by weight: 50 parts of high pressure polyethylene, 50 parts of linear polyethylene, 5 parts of black color masterbatch, 25 parts of filler, 5 parts of flame retardant,

[0056] The adhesive layer is an ethylene-vinyl acetate copolymer, and the mass content of vinyl acetate is 20%.

[0057] Add the release layer, filling layer, transition layer, and adhesive layer into different mixers according to the mass ratio and stir and dry for 15 minutes;

[0058]S2. Shearing and heating of screw plasticizing extrud...

Embodiment 3

[0063] S1, material preparation:

[0064] The release layer includes by weight: 80 parts of high pressure polyethylene, 20 parts of linear polyethylene, 8 parts of white color masterbatch, 30 parts of filler, 6 parts of flame retardant,

[0065] The filling layer includes by weight: 80 parts of high pressure polyethylene, 5 parts of black color masterbatch, 120 parts of calcium carbonate filling masterbatch, 10 parts of flame retardant,

[0066] The transition layer includes by weight: 80 parts of high pressure polyethylene, 20 parts of linear polyethylene, 8 parts of black color masterbatch, 30 parts of filler, 6 parts of flame retardant,

[0067] The adhesive layer is an ethylene-vinyl acetate copolymer, and the mass content of vinyl acetate is 21%.

[0068] Add the release layer, filling layer, transition layer, and adhesive layer into different mixers according to the mass ratio and stir and dry for 30 minutes;

[0069] S2. Shear heating of the screw plasticizing extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com