Preparation method of crude oil-water emulsion, and obtained oil-in-water emulsion

A water emulsification and crude oil technology, applied in the field of heavy oil thermal recovery, can solve the problems of poor fluidity and high crude oil viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

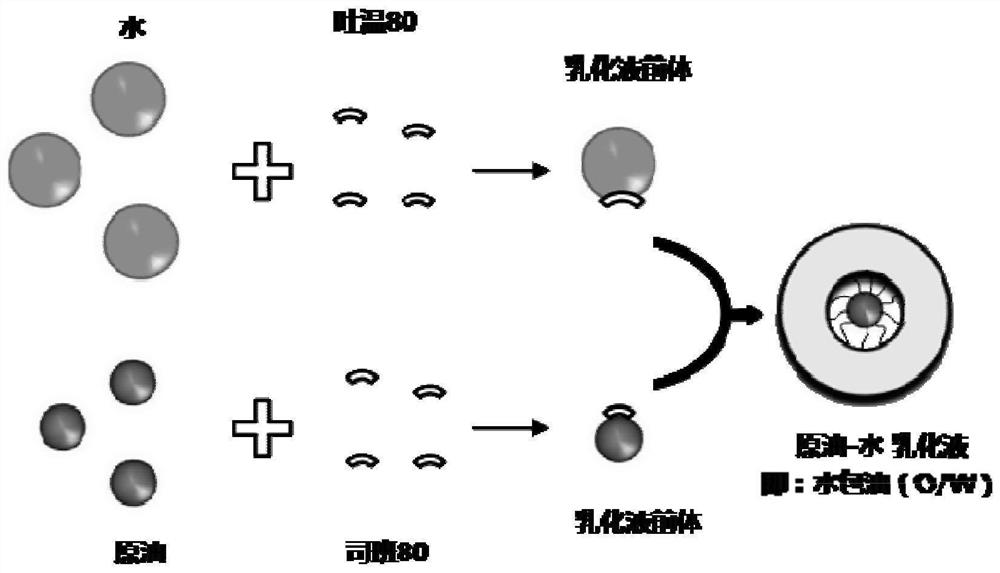

Method used

Image

Examples

Embodiment 1

[0039] 1) Span 80 and crude oil with a mass ratio of 1:25 in the water bath heating device, the water bath temperature is 45°C, and the disperser is used for stirring and dispersing. The speed of the disperser is 3000r / min, and the stirring and dispersing time is 30min to obtain the mixed liquid A ;

[0040] Mix Tween 80 with a mass ratio of 1:50 and deionized water, and stir and disperse through a disperser. The stirring and dispersing rate is 700r / min, and the stirring and dispersing time is 20min to obtain the mixed liquid B;

[0041] The mass ratio of crude oil in mixed solution A to mixed solution B deionized water is 1:4;

[0042] 2) Mix the mixed solution A and the mixed solution B to obtain the mixed solution C, emulsify at 45°C and a stirring rate of 2000r / min for 60 minutes, and obtain a crude oil-water emulsion after the end.

[0043] After testing, the crude oil-water emulsion in Example 1 has the characteristics of homogeneity, low viscosity, high fluidity and hi...

Embodiment 2

[0045] 1) Add Span 20 and crude oil with a mass ratio of 1:30 in the water bath heating device, the temperature of the water bath is 50°C, stir and disperse with a disperser, the speed of the disperser is 5000r / min, and the stirring and dispersing time is 20min to obtain a mixed liquid A;

[0046] Mix Tween 40 with a mass ratio of 1:60 and deionized water, stir and disperse through a disperser, the stirring and dispersing rate is 900r / min, and the stirring and dispersing time is 15min to obtain the mixed liquid B;

[0047] The mass ratio of crude oil in mixed solution A to mixed solution B deionized water is 3:7;

[0048] 2) Mix the mixed solution A and the mixed solution B to obtain the mixed solution C, emulsify at 50°C and a stirring rate of 2500r / min, the emulsification time is 45min, and obtain a uniformly dispersed crude oil-water emulsion after the end .

[0049] After testing, the crude oil-water emulsion of Example 2 has the characteristics of homogeneity, low viscosi...

Embodiment 3

[0051] 1) Add OP-10 and crude oil with a mass ratio of 1:27 in the water bath heating device, the temperature of the water bath is 48°C, use a disperser to stir and disperse, the speed of the disperser is 4000r / min, and the stirring and dispersing time is 25min to obtain a mixed solution A;

[0052] Mix sucrose ester S1670 with a mass ratio of 1:55 and deionized water, stir and disperse through a disperser, the stirring and dispersing rate is 800r / min, and the stirring and dispersing time is 17min to obtain the mixed solution B;

[0053] The mass ratio of crude oil in mixed solution A to mixed solution B deionized water is 1:3;

[0054] 2) Mix the mixed solution A and the mixed solution B to obtain the mixed solution C, emulsify at 46°C and a stirring rate of 2400r / min, the emulsification time is 50min, and obtain a uniformly dispersed crude oil-water emulsion after the end .

[0055] After testing, the crude oil-water emulsion of Example 3 has the characteristics of homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com